-

Setlhoa se Sintered se Hlatsoang Khase e Hloekileng Bakeng sa Lits'ebetso tse le 'Ngoe Tse Tlase tsa Phallo

Setlhopha se Sintered sa Setlhoeki sa Khase bakeng sa Likopo tse Leng, tse Tlase Phallo e Le 'ngoe E etselitsoe ho hloeka ho hoholo le lits'ebetso tsa bohloeki bo phahameng tse hlokang maemo a litšila...

Sheba lintlha -

Sefa sa Porous Metal Filter Media le OEM Sintered Stainless Steel Filter bakeng sa Khase ea Hydrogen

Mecha ea litaba ea porous metal filter ea boqapi ba hajoale e kenyelletsa yuniti e sefang e tlosang litšila ho khase ea haedrojene, le valve ea tsela e le 'ngoe e laolang ...

Sheba lintlha -

Sintered In-line Metal Gas Filter bakeng sa Sisteme ea Tlhoekiso ea Khase ea Semiconductor

Lisefa tsa khase ea tšepe e kentsoeng ka har'a mohala li sebetsa ho leleka litšila tse kenyelletsang mongobo, oksijene, carbon dioxide, carbon monoxide, hydrocarbons le carbonyls tsa tšepe ka ...

Sheba lintlha -

Sintered porous metal filter disc 20 micron bakeng sa tlhoekiso ea Khase le tlhahlobo

Finyella Karohano e Ke keng ea Bapisoa ea Khase/Solids ka Li-disc tsa HENGKO tsa Sintered Stainless Steel Filter! Sistimi ea rona ea ho sefa, e nang le sintered stainless ...

Sheba lintlha -

Sintered metal Gas / Solids Venturi Blowback (GSV) GSP filter OEM Services

Custom Sintered metal Gas/Solids Venturi Blowback (GSV) Filter ea GSP Sintered metal filters e sebelisitsoe bakeng sa ho sefa khase e chesang limela tse fapaneng ...

Sheba lintlha -

Sesefa sa Ultra Pure sa UHP se Hatelitsoeng sa Air Stainless High Pressure Inline sampling...

HENGKO Gas Sampling Filter e ka arola lintho tse tiileng le likhase ka mefuta e mengata e fapaneng ea ts'ebeliso. Lisebelisoa li kenyelletsa ho sefa, ho etsa lisampole, ho bentša ...

Sheba lintlha -

Sintered Stainless Stainless Stainless Steel Porous Metal Powder Filter e Sebelisitsoeng Bakeng sa Sampling ea Sensor ea Khase

Tlhaloso ea Lihlahisoa Karolo ea moea bakeng sa sampole ea li-sensor tsa khase, e sebelisetsoang ho fokotsa ho fetoha ha khatello Hlooho ea sampole ea khase ke g...

Sheba lintlha -

Sistimi ea Sampling bakeng sa Analyzer ea Khase - Sefa se Phahameng sa Khatello e Phahameng ea Ultra Pure UHP

HENGKO Sefahla sa khase se phahameng sa khatello e phahameng bakeng sa tšireletso e tšepahalang khahlanong le litšila. 'Maraka ona oa ho sefa, karohano le tlhoekiso o boetse o tlatselletsa ho ...

Sheba lintlha -

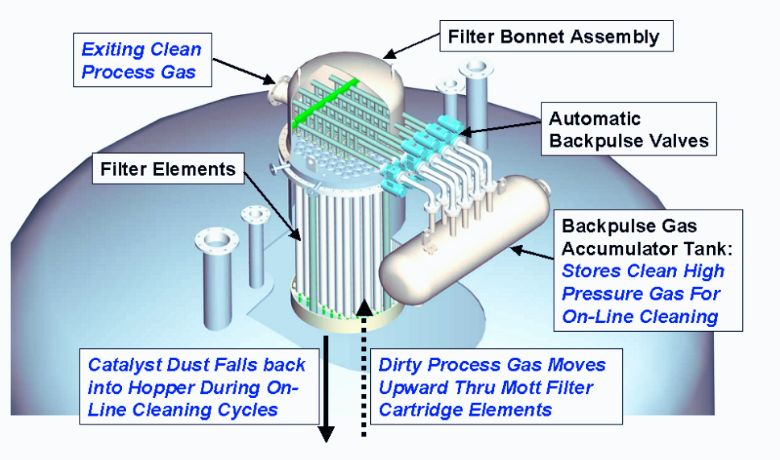

HENGKO Sintered Filter Cartridge for Process Gas and On-line Analysis

Tlhophiso ea Khase le Mehlala Bakeng sa Ts'ebetso ea Khase le Tlhahlobo ea Marang-rang Ho tlhotloa ha likhase ho bohlokoa mefuteng e mengata ea ts'ebeliso, empa ke limithara tse tharo feela ...

Sheba lintlha -

Bopaki ba ho phatloha Sintered Filtered Sensor Housing bakeng sa Ts'ebetso le Ts'ebeliso ea Khase ea Analytical...

Ntlo ea sensor ea khase ke lisebelisoa tsa tšireletso tse lumellang ho phalla ha likhase tse tukang ha li ntse li thibela ho khantša. The (sintered metal filter media) sensor ea khase ea ntlo ea ...

Sheba lintlha -

Lisebelisoa tsa Mollo oa Khase ea Khoebo ea Khoebo tse nang le Lialamo tsa Khase ea Tlhaho

Boloka Metsotsoana - Phoso ea Tšireletso ea Boloka Bophelo e lebisa liphellong tse bohloko. Tsebong ea khase, motsotsoana o mong le o mong oa bohlokoa, le ho khetha tharollo e nepahetseng ea ho fumana khase ho...

Sheba lintlha -

Mofuta oa Marang-rang oa Smart Single Industrial Gas Detector – GASH-AL01

Sesebelisoa se le seng sa khase se sebelisoa haholo ho bona khase e tukang e lutlang kapa khase e chefo e pepesehileng tikolohong. E ka sebeletsa indasteri ea petroleum ch ...

Sheba lintlha

Mefuta ea ho Filtration ea Khase

Joalo ka ha re Tseba, Ho na le mefuta e mengata e fapaneng ea tlhoekiso ea khase, ho latela ts'ebeliso e ikhethileng.

E meng ea mefuta e atileng haholo ea ho sefa khase e kenyelletsa tse latelang:

1. Filtration e felletseng:

Mofuta ona oa ho sefa o tlosa likaroloana tsohle tsa boholo bo itseng kapa tse kholoanyane. Li-filters tse felletseng li sebelisoa hangata

lits'ebetso tse mahlonoko moo le likaroloana tse nyane li ka bakang mathata, joalo ka semiconductor

indasteri le lisebelisoa tsa bongaka.

2. Filtration ea Coalescing:

Mofuta ona oa ho sefa o tlosa marotholi a mokelikeli ho tsoa khase. Li-filters tsa coalescing hangata li sebelisoa ho

lisebelisoa moo mongobo o ka bakang mathata, joalo ka tlhahiso ea oli le khase le ho

tsamaiso ea moea e hatelitsoeng.

3. Filtration ea Adsorptive:

Mofuta ona oa ho sefa o tlosa likhase le mouoane ho tsoa phallong ea khase ka adsorption. Li-filters tsa Adsorptive

hangata li sebelisoa lits'ebetsong moo taolo ea mesi e hlokahalang, joalo ka lifemeng tsa motlakase le ho

lisebelisoa tsa ho sebetsana le lik'hemik'hale.

3. Filtration ea Catalytic:

Mofuta ona oa ho sefa o sebelisa sesebelisoa ho fetola likhase tse kotsi hore e be likhase tse seng kotsi haholo. Li-filters tsa Catalytic

hangata li sebelisoa lits'ebetsong moo taolo ea mesi e hlokahalang, joalo ka likoloing le lifemeng tsa indasteri.

Ntle le mefuta ena e akaretsang ea tlhoekiso ea khase, ho boetse ho na le mefuta e mengata e ikhethileng ea tlhoekiso ea khase, joalo ka:

* HEPA (moea o sebetsang hantle haholo oa moea):

Li-filters tsa HEPA li etselitsoe ho tlosa likaroloana tse nyane haholoho tloha ho khase ea khase, ho theohela ho li-microns tse 0,3 ka bophara.

Lisefe tsa HEPA li sebelisoa hangata lipetlele le libakeng tse ling tse hloekileng.

1. ULPA (moea o kenang o tlase haholo):

Lisefe tsa ULPA li sebetsa hantle ho feta lihloela tsa HEPA, li tlosa 99.999%ea likaroloana 0,12 microns bophara

kapa kholoanyane. Li-filters tsa ULPA hangata li sebelisoa lits'ebetsong tse mahlonoko moo le tsona lilikaroloana tse nyane li ka baka mathata,

joalo ka indastering ea meriana le tlhahisong ea li-semiconductor.

2. Kemiso ea khabone e kentsoeng:

Li-filters tsa carbon tse sebetsang li sebelisoa ho tlosa mouoane oa tlhaho le litšila tse lingmolapo oa khase. E kentswe

li-filters tsa khabone hangata li sebelisoa lits'ebetsong moo taolo ea monko e hlokahalang, joalo ka holisebelisoa tsa ho hloekisa metsi a litšila

le litsing tsa ho lokisa lijo.

Mofuta oa ho hloekisa khase o molemo ka ho fetisisa bakeng sa ts'ebeliso e itseng o itšetlehile ka lintlha tse 'maloa, ho kenyelletsa le mofuta oa khase e tlhotliloeng, boholo ba likaroloana tse lokelang ho tlosoa, le boemo bo lakatsehang ba ho sefa hantle.

Likarolo tse ka Sehloohong tsa Sintered Metal Gas Filters

Sintered metal gas filter ke mofuta oa theknoloji e hloekisang khase e sebelisang lisebelisoa tsa tšepe tse sirelelitsoeng ho sefa likhase. Tse ling tsa likarolo tsa mantlha tsa ho sefa ha khase ea tšepe ea sintered li kenyelletsa tse latelang:

1. Matla a phahameng a ho sefa:Li-filters tsa tšepe tse sirelelitsoeng li na le ts'ebetso e phahameng, ho bolelang hore li ka tlosa litšila tse tsoang likhaseng.

2. Nako e telele:Li-filters tsa tšepe tse entsoeng ka sintered li entsoe ka tšepe, li etsa hore li tšoarelle nako e telele ho feta li-filters tse ling. Li khona ho mamella mocheso o phahameng le likhatello 'me li khona ho mamella ho bola.

3. Mefuta-futa:Lisefe tsa tšepe tse sirelelitsoeng li ka sebelisoa lits'ebetsong tse fapaneng, ho kenyeletsoa ho sefa moea, khase le maro.

4.Customizability:Li-filters tsa tšepe tse sirelelitsoeng li ka etsoa ka mokhoa o ikhethileng ho fihlela litlhoko tse ikhethang tsa lits'ebetso tse fapaneng. Ka mohlala, li ka etsoa ka boholo bo fapaneng le libopeho tse fapaneng ho lekana lisebelisoa tse fapaneng.

5. Ho hanyetsa lik'hemik'hale: Li-filters tsa tšepe tse sintered li hanyetsana le mefuta e mengata ea lik'hemik'hale, li etsa hore li tšoanelehe ho sebelisoa libakeng tse thata.

6. Ho mamella mocheso o phahameng: Li-filters tsa tšepe tse sintered li ka sebetsa ka mocheso o phahameng, li etsa hore li tšoanelehe bakeng sa lisebelisoa tse phahameng tsa mocheso.

7. Ho theoha ha khatello e tlaase: Li-filters tsa tšepe tse sintered li na le ho theoha ha khatello e tlaase, ho bolelang hore ha li hanyetse haholo ho phalla ha khase ka tsona. Sena se etsa hore li sebelise motlakase hantle 'me se ka thusa ho fokotsa litšenyehelo tsa ts'ebetso.

8. Nako e telele ea bophelo: Lisefe tsa tšepe tse sirelelitsoeng li na le nako e telele ea bophelo 'me ha li hloke ho nkeloa sebaka khafetsa joalo ka lihloela tse ling. Sena se ka thusa ho fokotsa litšenyehelo tsa tlhokomelo le ho fokotsa nako.

Tšebeliso e ka Sehloohong ea Sesefo sa Khase

Setlhopha sa khase se sebelisoa lits'ebetsong tse fapaneng ho tlosa litšila likhase. Tse ling tsa lits'ebetso tsa mantlha tsa tlhoekiso ea khase li kenyelletsa:

1. Mekhoa ea indasteri:Hangata ho hloekisa khase ho sebelisoa ho tlosa litšila tse kang li-particulate, mongobo le lik'hemik'hale tse tsoang likhase tse sebetsang.

2.Ho hloekisa moea: Sefefo sa khase se sebelisoa litsamaisong tsa tlhoekiso ea moea ho tlosa litšila tse joalo ka lerole, lintho tse thobang, le mouoane oa lik'hemik'hale.

3. Thepa ea bongaka: Ho hloekisa khase ho sebelisoa lisebelisoa tsa bongaka tse kang li-ventilator le mechine ea anesthesia ho tlosa litšila tse tsoang likhase tse phefumolohang.

4. Ho lokisa lijo le lino: Ho hloekisoa ha khase ho sebelisoa ho lokisa lijo le lino ho tlosa litšila tse tsoang likhaseng tse sebelisoang tlhahisong le ho pakang lijo le lino.

5. Tšireletso ea tikoloho: Ho hloekisa khase ho sebelisoa lits'ebetsong tsa ts'ireletso ea tikoloho ho tlosa litšila tse tsoang likhase tse hlahisoang ke mekhoa ea indasteri kapa likoloi.

6. Tlhahiso ea matla: Ho hloekisoa ha khase ho sebelisoa tlhahisong ea matla, joalo ka ts'ebetsong ea khase ea tlhaho le phepelong ea matla, ho tlosa litšila tse tsoang likhase tse sebelisoang e le mafura.

7. Lisebelisoa tsa laboratori: Ho hloekisa khase ho sebelisoa lisebelisoa tsa laboratori ho tlosa litšila likhase tse sebelisoang lipatlisisong tsa saense le liteko.

8. Sepakapaka:Ho hloekisoa ha khase ho sebelisoa indastering ea sepakapaka ho tlosa litšila likhase tse sebelisoang ho tsamaiseng lifofane le lits'ebetsong tse tšehetsang bophelo.

Ke Mofuta Ofe oa Khase o Hlokahalang ho Feta Khase?

Ho hloekisa khase ke ts'ebetso ea bohlokoa indastering le lits'ebetsong tse ngata. Mefuta e fapaneng ea likhase e hloka mekhoa e ikhethang ea ho sefa, ho latela litšoaneleho tsa eona tse ikhethileng le ts'ebeliso e teng. Mona ke mefuta e meng e tloaelehileng ea likhase tseo hangata li hlokang ho sefshoa:

1. Lisefe tsa Moea tsa Tlhaho :Ho hloekisa moea ke e 'ngoe ea mekhoa e tloaelehileng le e hlokahalang, haholo-holo libakeng tseo boleng ba moea bo ka amang bophelo bo botle ba batho kapa boleng ba sehlahisoa haholo. Ka mohlala, ha ho etsoa liphaposi tse hloekileng, lipetlele, kapa tsamaiso ea HVAC, ho sebelisoa lifensetere tsa moea ho tlosa lintho tse silafatsang, lintho tse thobang maikutlo le lintho tse silafatsang likokoana-hloko.

2. Lisefe tsa Turbine ea Khase:Ho sefa khase ea tlhaho ho bohlokoa indastering ea oli le khase. Mokhoa ona o thusa ho tlosa litšila le litšila tse kang lerōle, litšila, oli, metsi le li-condensate tse ka lebisang ho bola le ho senyeha ha lisebelisoa le liphaephe.

3. Sefe ea Haedrojene:Hangata ho hlokahala ho hloekisa haedrojene liseleng tsa mafura le limela tsa tlhahiso ea haedrojene. Mokhoa oa ho hloekisa o tlosa litšila tse kang carbon monoxide, carbon dioxide, le methane tse ka amang tšebetso ea lisele tsa mafura kapa ho hloeka ha haedrojene e hlahisoang.

4. Lisefe tsa oksijene:Libakeng tsa bongaka le tsa indasteri, ho hloekisa oksijene hoa hlokahala ho tlosa litšila tse ka senyang tšireletso ea mokuli kapa mekhoa ea indasteri. Ho hloekisoa ha khase ea oksijene ho tiisa hore e bolokehile ebile e sebetsa hantle bakeng sa tšebeliso ea lits'ebetso tse kang phepelo ea oksijene ea bongaka, ho seha tšepe kapa ho cheselletsa.

5. Sefa sa naetrojene:Liindastering tse kang ho paka lijo, lisebelisoa tsa elektroniki le tsa meriana, khase ea naetrojene hangata e sefshoa ho netefatsa bohloeki le ho thibela tšilafalo ea lihlahisoa. Ka mohlala, ha ho pakoa lijo, naetrojene e tlhotliloeng e ka thusa ho boloka bohloeki ka ho tlosa oksijene sebakeng se ka bakang ho senyeha ha lijo.

6. Sulfur Hexafluoride (SF6):SF6 ke khase e sireletsang matla e sebelisoang lisebelisoa tsa motlakase joalo ka li-circuit breaker le switchgear. Ho hlophisoa ha khase ena ho bohlokoa nakong ea ho hlaphoheloa le ho sebelisoa hape ho tlosa litšila tse ka amang thepa ea eona e sireletsang kapa ho senya thepa.

7. Sefe ea Carbon Dioxide (CO2) :Liindastering tse kang ho ritela le ho noa, ho hloekisa carbon dioxide ho bohlokoa ho netefatsa bohloeki ba CO2 e sebelisetsoang mekhoa ea carbonation. CO2 e sa hloekang e ka ama tatso le boleng ba sehlahisoa sa ho qetela.

8. Lisefe tsa Helium:Lits'ebetsong tse kang mechini ea MRI, helium e tlhotliloeng ho netefatsa bohloeki ba eona le ts'ebetso e nepahetseng ea lisebelisoa. Litšila tse ka har'a helium li ka baka ho se sebetse hantle ha pholiso 'me tsa senya lisebelisoa.

Lipotso tsa Sefe ea Khase

1. Sefe ea Khase ke Eng, Hona Ke Hobane'ng ha e le Bohlokoa?

Ho hloekisoa ha khase ho bolela mokhoa oa ho tlosa litšila ho tsoa khase. Mabaka a mang a kenyelletsa ho ntlafatsa boleng ba khase, ho sireletsa lisebelisoa hore li se ke tsa senyeha ke lintho tse silafatsang, le ho netefatsa polokeho ea basebetsi. Ho hloekisa khase ke ts'ebetso ea bohlokoa liindastering tse ngata, ho kenyeletsoa ts'ebetso ea lik'hemik'hale, tlhahiso ea meriana, tlhahiso ea oli le khase, le tlhahiso ea matla.

2. Sefahla sa khase ea sintered se sebetsa joang setšoantšo sa moralo?

Lisefa tsa khase ea tšepe e sirelelitsoeng li sebetsa holima melao-motheo ea ho tlhotla ka botebo le ho tlhotla bokaholimo. Li entsoe ka ho hatella liphofshoana tsa tšepe hore li be sebopeho se hlalositsoeng le ho futhumatsa thepa e kopantsoeng (ntle le ho fihla moo ho qhibilihang) ho etsa mehaho e matla le e nang le masoba.

Mona ke tlhaloso e nolofalitsoeng ea hore na lihloela tsa khase ea sintered li sebetsa joang:

-

Inlet:Khase e sa sefshoang e kenngoa ka har'a sefe ea tšepe e sirelelitsoeng. Khase ena e ka ba le litšila tse fapaneng joalo ka lerole, li-particulate kapa litšila tse ling ho latela mohloli le ts'ebeliso ea khase.

-

Mokhoa oa ho Filtration:Ha khase e feta ka har'a sefe ea tšepe e nang le masoba, litšila li qabeletsoe ka har'a marang-rang a rarahaneng a masoba. Filtration e ka etsoa ka litsela tse peli:

-

Sefeta se Tebileng:Ts'ebetsong ena, litšila li ts'oaroa 'me li bolokoa ho pholletsa le botebo ba mecha ea litaba. E nepahetse bakeng sa ho tlosa likaroloana tse nyane mme e fana ka bokhoni bo phahameng ba ho ts'oara litšila.

-

Sefe ea Bokaholimo:Ts'ebetsong ena, litšila li qabeletsoe ka holim'a sefe. E sebetsa hantle bakeng sa likaroloana tse kholoanyane 'me e li thibela ho feta ka sefeng.

-

-

Outlet:Khase e hloekisitsoeng, e se nang litšila, ebe e tsoa ka har'a sefe 'me e tsoela pele ho ea ts'ebetsong e reriloeng, ebang ke ts'ebetso ea tlhahiso, sesebelisoa se itseng, kapa tsamaiso ea indasteri.

Lisefe tsa tšepe tse sirelelitsoeng li tsebahala haholo ka ho tšoarella ha tsona, matla a holimo a mochini, le ho hanyetsa mocheso o phahameng. Li ka hloekisoa le ho sebelisoa hape ka makhetlo a mangata, e leng se tlatsetsang ho boloka litšenyehelo le ho boloka tikoloho. Ba boetse ba khona ho sebetsana le phapang ea khatello e phahameng, e etsang hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng tse thata.

A na u hloka tharollo e sebetsang hantle ea ho sefa bakeng sa ts'ebeliso ea hau e ikhethileng? Ikopanye le sehlopha sa rona sa HENGKO hoka@hengko.com. Re se re ikemiselitse ho fana ka likeletso tsa litsebi le litharollo tse etselitsoeng ho fihlela litlhoko tsa hau.

3. Melemo ea ho sebelisa sintered tšepe bakeng sa filtara khase ke efe?

Ho na le melemo e mengata ea ho sebelisa sintered metal bakeng sa ho sefa khase:

1.) Matla a phahameng le ho tšoarella:Li-filters tsa tšepe tse sintered li matla ebile ha li khone ho senya, li etsa hore li tšoanelehe bakeng sa lisebelisoa tse phahameng tsa khatello le mocheso o phahameng.

2.)Sebaka se phahameng:Sebopeho sa porous sa li-filters tsa tšepe tsa sintered se fana ka sebaka se seholo sa holim'a hore litšila li tšoasoe, ho eketsa bokhoni ba tsona ba ho hloekisa.

3.)Ho hanyetsa lik'hemik'hale:Lisefe tsa tšepe tse sirelelitsoeng li hanela lik'hemik'hale tse ngata 'me li ka sebelisoa ka likhase tse senyang.

4.)Customizability:Li-filters tsa tšepe tse sirelelitsoeng li ka etsoa ka boholo bo fapaneng, libopeho le litlhophiso ho fihlela litlhoko tse khethehileng tsa ho sefa.

5. Ke liindasteri life tse atisang ho sebelisa sintered metal gas filtration?

Sintered metal gas filtration hangata e sebelisoa liindastering tse fapaneng, ho kenyeletsoa ts'ebetso ea lik'hemik'hale, tlhahiso ea meriana, tlhahiso ea oli le khase, tlhahiso ea matla le tlhoekiso ea moea. Liindastering tsena, li-filters tsa tšepe tsa sintered li sebelisoa ho tlosa litšila tse tsoang melapong ea khase ho sireletsa lisebelisoa, ho ntlafatsa boleng ba sehlahisoa le ho netefatsa polokeho ea basebetsi.

6. Boholo le sebōpeho sa sefe ea sintered tšepe se ama ts'ebetso ea sona joang?

Boholo le sebōpeho sa filthara ea tšepe e sintered e ka ama ts'ebetso ea eona haholo. Sefefo se seholo se tla ba le sebaka se seholoanyane mme se ka khona ho sefa litšila tse ngata, empa hape se ka ba le ho theoha ho hoholo ha khatello, ho ka fokotsang sekhahla sa phallo ea khase. Ka mokhoa o ts'oanang, sebopeho sa filthara se ka ama ts'ebetso ea sona. Mohlala, sefe e nang le pleated e kanna ea ba le sebaka se holimo mme sa sebetsa hantle haholo ho ts'oara litšila, empa hape se ka ba le ho theoha ho hoholo ha sefa ho feta sefe se sa keneng.

7. Na lihloela tsa khase ea tšepe e sirelelitsoeng li ka sebelisoa ka likhase tse senyang kapa tse senyang?

Li-filters tsa tšepe tse entsoeng ka sintered li ka sebelisoa ka likhase tse senyang kapa tse senyang. Lisefe tsa tšepe tse sirelelitsoeng li hanana le lik'hemik'hale tse ngata 'me li khona ho mamella mocheso o phahameng, li etsa hore li tšoanele libaka tse thata. Leha ho le joalo, ho bohlokoa ho khetha filthara ea tšepe e sintered e lumellanang le likhase tse ikhethileng tse sebelisoang le ho boloka sefahla hantle ho netefatsa bophelo ba sona bo bolelele.

8. U hlokomela joang le ho hloekisa lihloela tsa khase tsa tšepe tse sirelelitsoeng hantle joang?

Tlhokomelo e nepahetseng le ho hloekisoa ha li-filters tsa tšepe tse sintered ke tsa bohlokoa ho netefatsa hore li sebetsa le ho phela nako e telele. Litaelo tse akaretsang tsa ho boloka lihloela tsa tšepe tse sirelelitsoeng ke tsena:

Latela likhothaletso tsa moetsi bakeng sa tlhokomelo le tlhoekiso ea sefe.

Kamehla hlahloba lihloela bakeng sa matšoao a tšenyo kapa tšilafalo e feteletseng.

Sebelisa moea o hatelitsoeng o hloekileng, o omileng ho butsoela.

9. Mefuta e fapaneng eali-filters tsa tšepe tsa tšepe tse sinterede fumaneha?

Ho na le mefuta e mengata ea li-filters tsa tšepe tse sintered tse fumanehang, ho kenyelletsa:

1. Li-filters tse pentiloeng:Li-filters tsena li na le sebaka se seholo 'me li entsoe ka wrinkles kapa mameno a li-filters tsa media. Hangata li sebelisoa lits'ebetsong tsa phallo e phahameng mme li ka etsoa ka boholo le libopeho tse fapaneng.

2. Lisefe tse tebileng:Li-filters tsena li entsoe ka lera la phofo ea tšepe e sirelelitsoeng e koahetsoeng kapa e phuthetsoe ho pota-pota mohaho oa tšehetso. Lintho tse silafatsang li qabeletsoe ka hare ho botebo ba sefe ho e-na le holim'a metsi.

3. Lisefa tsa skrine:Li-filters tsena li entsoe ka letlooeng la lithapo tsa tšepe tse sirelelitsoeng kapa likhoele 'me li sebelisetsoa ho tlosa likaroloana tse kholo tsa khase.

4. Lisefa tsa Membrane:Li-filters tsena li na le lera le tšesaane la tšepe e sirelelitsoeng holim'a mohaho oa ts'ehetso 'me li sebelisetsoa ho tlosa likaroloana tse nyenyane tse tsoang melapong ea khase.

10. U khetha sefe se nepahetseng sa sintered metal gas bakeng sa kopo ea hau?

Ho na le lintlha tse 'maloa tse lokelang ho nahanoa ha u khetha filthara ea khase ea sintered metal, ho kenyelletsa:

*Mofuta oa khase e tlhotliloeng:

Likhase tse fapaneng li ka hloka li-filters tse fapaneng kapa media media.

* Lintho tse silafatsang li tlosoa:

Boholo le mofuta oa litšila li tla khetholla boholo ba pore le sebaka se ka holimo sa sefe se hlokahalang.

* Sekhahla sa phallo ea khase:

Sesefa se tlameha ho sebetsana le sekhahla se hlokahalang sa phallo ntle le ho baka ho theoha ho feteletseng.

* Thempereichara ea ts'ebetso le khatello:

Sefahla se tlameha ho khona ho mamella mocheso oa ts'ebetso le khatello ea sistimi.

* Khokahano ea lik'hemik'hale ea filthara:

Sesefa se tlameha ho hanana le lik'hemik'hale tse ka har'a khase.

11. Mefokolo ea ho sefa khase ea tšepe ea sintered ke efe?

Tse ling tsa mefokolo ea ho sefa ha khase ea sintered metal e kenyelletsa tse latelang:

1. Ho theoha ha khatello e phahameng:Li-filters tsa tšepe tse sintered li ka ba le ho theoha ha khatello e phahameng, ho fokotsa sekhahla sa phallo ea khase.

2. Ho tlosoa ho fokolang ha likaroloana tse nyenyane:Lisefe tsa tšepe tse sirelelitsoeng li ka 'na tsa se ke tsa tlosa likaroloana tse nyane, joalo ka tse nyane ho feta masoba a sefe.

3. Litšebelisano tse fokolang tsa lik'hemik'hale:Le hoja li-filters tsa tšepe tse entsoeng ka sintered li hanyetsa lik'hemik'hale tse ngata, li ka 'na tsa se ke tsa tšoanela likhase tsohle.

12. Sefate sa khase ea sintered se bapisoa joang le mefuta e meng ea ho sefa khase?

Sintered metal gas filtration e na le melemo e mengata ho feta mefuta e meng ea khase, ho kenyelletsa:

1. Matla a phahameng le ho tšoarella:Li-filters tsa tšepe tse sintered li matla ebile ha li khone ho senya, li etsa hore li tšoanelehe bakeng sa lisebelisoa tse phahameng tsa khatello le mocheso o phahameng.

2. Sebaka se phahameng:Sebopeho sa porous sa li-filters tsa tšepe tsa sintered se fana ka sebaka se seholo sa holim'a hore litšila li tšoasoe, ho eketsa bokhoni ba tsona ba ho hloekisa.

3.Customizability:Li-filters tsa tšepe tse sirelelitsoeng li ka etsoa ka boholo bo fapaneng, libopeho le litlhophiso ho fihlela litlhoko tse khethehileng tsa ho sefa.

Leha ho le joalo, filthara ea khase ea sintered e kanna ea se be khetho e ntle ka ho fetisisa. Ka mohlala, lihloela tse ling, tse kang activated carbon filters, li ka atleha ho tlosa lintho tse silafatsang kapa tse loketseng ho sebelisoa le likhase tse itseng.

13. Na ho na le menahano ea polokeho eo u lokelang ho e ela hloko ha u sebelisa li-filters tsa tšepe tse sintered?

E, ho na le lintlha tse 'maloa tsa polokeho tseo u lokelang ho li ela hloko ha u sebelisa li-filters tsa tšepe tse sintered:

Latela litaelo tsa moetsi mabapi le ho tšoara le ho kenya lihloela.

E-ba hlokolosi ha u tšoara li-filters, kaha li ka 'na tsa e-ba bohale kapa li na le mathōko a makukuno.

Ha u tšoara li-filters, apara lisebelisoa tse sireletsang, tse kang liatlana le likhalase tsa tšireletso.

Sireletsa li-filters ka nepo ho li thibela hore li se ke tsa lokoloha kapa tsa lahleha nakong ea ts'ebeliso.

Hlahloba lihloela khafetsa bakeng sa matšoao a tšenyo kapa tšilafalo e feteletseng 'me u li fetole ha ho hlokahala.

Latela mekhoa e nepahetseng ea ho hloekisa le ho boloka li-filters ho netefatsa hore li sebetsa le ho phela nako e telele.

Ela hloko ho lumellana ha lik'hemik'hale tsa li-filters 'me u li sebelise feela ka likhase tseo li etselitsoeng ho sebetsana le tsona.

Ke tšepa hore boitsebiso bona bo thusa! Ntsebise haeba u na le lipotso tse ling.

Are you interested in our sintered metal gas filters and have questions about our products? We'd love to help! Email us at ka@hengko.com, and we'll assist you. Our team of experts is here to answer any questions and help you find the right solution for your gas filtration needs. Don't hesitate to reach out – we look forward to hearing from you!

Bakeng sa Lihlahisoa tse ling tsa Lisefa tsa Khase, U ka boela ua sheba Joalo Latela Video.

Li-filters tsa Sintered Metal li ka U Thusa ho Sefa Bongata ba Khase Betere, Mohlomong U ka Lekola lintlha le ho Odara Mehlala e meng ea ho Lekola,

Any more questions for the Gas Filtration and Custom Service, Please feel free to contact us by email ka@hengko.com or send

ho botsa ka mokhoa o latelang. Kea leboha!