Joalo ka ha re Tseba ho fihlela Joale, theknoloji ea Filtration e bapala karolo ea bohlokoa likarolong tse ngata tsa bophelo ba rona le indastering,

ho ama ntho e 'ngoe le e 'ngoe ho tloha moeeng oo re o hemang ho ea metsing ao re a noang le lihlahisoa tseo re li sebelisang. Ke ts'ebetso

se arolang makumane a fanyehiloeng ho lero (gase kapa lero) ka ho a fetisa ka mokoallo o nang le masoba o bitsoang sefe.

Filtration ke ea bohlokoa ka mabaka a fapaneng:

* Tlhoekiso:

Ho tlosa litšila tse tsoang marong le likhase, ho li etsa hore li bolokehe ho sebelisoa kapa ho sebelisoa mekhoeng e fapaneng.

* Tshireletso:

Ho thibela likaroloana tse kotsi ho kena lisebelisoa le litsamaiso tse hlokolosi, ho netefatsa hore li sebetsa hantle

le ho lelefatsa bophelo ba bona.

* Tšireletso ea tikoloho:

Ho tlosa litšila moeeng le metsing, ho kenya letsoho ho hloekileng ha tikoloho.

* Ho hlaphoheloa ha lisebelisoa:

Ho arola lisebelisoa tsa bohlokoa ho maro, ho li nolofalletsa ho sebelisoa hape le ho fokotsa litšila.

* Boleng ba sehlahisoa:

Ho etsa bonnete ba hore lihlahisoa li finyella litekanyetso tse lakatsehang tsa bohloeki le ho hlaka.

Sebakeng sa theknoloji ea filtration, re tsepamisa maikutlo ho

mefuta e 'meli e fapaneng:Khase le Mokelikeli.

Leha ho le joalo, ke habohlokoa ho hlokomela hore hase likhase tsohle le lino tse nang le metsi tse tšoanang, 'me ka hona, li hloka ho lokisoa.

mekhoa ea ho sefaho netefatsa bohloeki le boleng bo phethahetseng. Mokhoa ona o hlophisitsoeng ke senotlolo sa ho fumana se molemohali

khase e ka bang teng kapa lero bakeng sa tse latelangmekhoa ea tlhahiso.

Ka ho utloisisa le ho kenya ts'ebetsong mekhoa e khethehileng ea ho hloekisa mefuta e fapaneng ea likhase le lino,

re ka khona haholontlafatsa bohlwahlwa le bohlwahlwa ba maikemisetso a rona a tlhahiso.

Tlhophiso ea Khase

Ho hloekisoa ha khase ke mokhoa oa ho tlosa likaroloana tse sa batleheng le litšila tse tsoang khase. E ea bapala

karolo ea bohlokoa lits'ebetsong tse fapaneng tse kang tlhoekiso ea moea, ts'ebetso ea khase ea indasteri, le ts'ireletso e hlokolosi

thepa. Mona ke mefuta e meng ea mantlha ea mahlale a ho sefa khase:

1. Lisefe tsa Mechini:

Li-filters tsena li nka likaroloana ho latela boholo ba tsona. Hangata ba sebelisa letlooeng kapa lera le nang le li-pores

di nyane hofeta le makumane a tlokoang. Ha khase e feta ka har'a sefe, likaroloana li qabeletsoe

bokahodimong ba lera.

Mefuta ea Lisefe tsa Mechini:

* Lifilimi tse tebileng:

Tsena li na le sebopeho se teteaneng, se nang le fiber e thibelang likaroloana tse ka har'a lihlopha tsa tsona.

Li sebetsa hantle bakeng sa ho tlosa likaroloana tse kholoanyane empa li ka ba le ho theoha ha khatello e phahameng.

* Lifilimi tsa Membrane:

Tsena li na le lera le lesesaane, le nang le masoba le lumellang limolek'hule tsa khase hore li fete ha li ntse li boloka likaroloana tse kholoanyane.

Ka tloaelo li sebetsa hantle ho feta lihloela tse tebileng 'me li na le khatello e tlase.

2. Lisefe tsa Adsorption:

Lisefe tsena li sebelisa lisebelisoa tse kang khabone e kentsoeng ho ts'oara limolek'hule. Thepa ea adsorbent e na le e kholo

sebaka se ka hodimo se nang le masoba a hohelang le ho tshwara dimolekhule tsa kgase. Ha khase e ntse e feta sefeneng,

limolek'hule tse sa batleheng li adsorbed holim'a adsorbent.

Mefuta ea li-filters tsa Adsorption:

* Li-filters tsa khabone tse kentsoeng:

Ena ke mofuta o atileng haholo oa li-filters tsa adsorption. Activated carbon ke a

lintho tse nang le porous tse ngata tse ka adsorb mefuta e mengata ea likhase.

* Lifilimi tsa sieve ea molek'hule:

Tsena li sebelisa lisebelisoa tsa zeolite ho khetha limolek'hule tse khethehileng.

3. Lisefe tsa Lik'hemik'hale:

Lisefe tsena li sebelisa lintho tse sebetsang ho fokotsa likhase tse kotsi. The chemical reactions converts the

khase e kotsi sehlahisoang se hlokang kotsi se ka lokolloang kapa ho lahloa ka mokhoa o bolokehileng.

Mefuta ea Lisefe tsa Lik'hemik'hale:

* Lisefe tsa Scrubber: Tsena li sebelisa tharollo ea mokelikeli ho monya le ho arabela ka khase e sa batleheng.

* Lisefe tsa Chemisorption: Tsena li sebelisa lisebelisoa tse tiileng ho arabela le ho tlosa khase e sa batleheng.

Ts'ebeliso ea Sefe ea Khase:

* Ho hloekisa moea:

Ho tlosa lerōle, lintho tse thobang, le lintho tse silafatsang moeeng o ka hare le o ka ntle.

* Ts'ebetso ea khase ea indasteri:

Ho arola litšila ho oli le khase ho hlahisa libeso tse hloekileng.

* Ho sireletsa lisebelisoa tse hlokolosi:

Ho thibela likaroloana tse kotsi ho kena lisebelisoa tse bobebe.

* Likopo tsa bongaka:

Ho fana ka moea o hloekileng bakeng sa mekhoa ea bongaka.

* Tšireletso ea tikoloho:

Ho tlosa litšila tse tsoang liindastering.

Ho khetha theknoloji e nepahetseng ea ho hloekisa khase ho itšetlehile ka lintlha tse 'maloa, ho kenyelletsa:

* Boholo le mofuta oa likaroloana tse lokelang ho tlosoa

* Boemo bo lakatsehang ba bohloeki

* Sekhahla sa phallo ea khase

* Theko le ho rarahana ha tšebetso

Ho bohlokoa ho buisana le setsebi se tšoanelehang sa ho hloekisa ho fumana mofuta o nepahetseng oa sefe bakeng sa hau

ditlhoko tse itseng.

Mokelikeli oa Mokelikeli

Mokelikeli o hloekisang ke mokhoa oa ho tlosa likaroloana tse sa batleheng le litšila tse tsoang molapong oa metsi.

Ho bohlokoa bakeng sa lits'ebetso tse fapaneng, ho kenyelletsa kalafo ea metsi, ts'ebetso ea lik'hemik'hale, lijo le

tlhahiso ea seno. Mona ke mefuta e meng ea mantlha ea mahlale a filtration a metsi:

1. Lisefe tsa Bokaholimo:

Lisefe tsena li tšoasa likaroloana ka holim'a sesefa. Hangata ba sebelisa letlooeng kapa skrineng

masoba a manyane hofeta makumane a tla ntšoa. Ha mokelikeli o feta har'a sefe, likaroloana

li qabeletsoe ka holim'a skrine.

Mefuta ea li-Filters tsa Surface:

* Lifilimi tsa skrineng:

Ena ke mofuta o bonolo ka ho fetisisa oa sefe ea holim'a metsi. Li entsoe ka letlooeng la tšepe le nang le masoba

tse kgolo ka ho lekaneng ho dumella lero ho feta empa tse nyane ho lekana ho tshwasa makumane a maholo.

* Lifilimi tsa cartridge:

Tsena li na le mecha ea phatlalatso e entsoeng ka pampiri, lesela kapa lisebelisoa tse ling.

Li fumaneha ka mefuta e fapaneng ea boholo ba pore ho tlosa boholo bo fapaneng ba likaroloana.

2. Lisefe tse tebileng:

Li-filters tsena li nka likaroloana ka har'a matrix a thepa ea sefe. Hangata li entsoe ka botenya,

lisebelisuoa tsa fibrous tse tšoasang likaroloana ka har'a lihlopha tsa tsona. Li-filters tse tebileng li sebetsa hantle bakeng sa ho tlosa tse nyane

likaroloana empa e ka ba le ho theoha ha khatello e phahameng.

Mefuta ea Lisefe tse tebileng:

* Lifilimi tse tebileng:Tsena li entsoe ka thepa e kang selulose, likhoele tsa khalase kapa likhoele tsa maiketsetso.

Li sebetsa hantle bakeng sa ho tlosa mefuta e mengata ea boholo ba likaroloana, ho kenyeletsa libaktheria le likokoana-hloko.

* Lisefa tsa maqeba:Tsena li entsoe ka ho sokela lesela la fibrous ho potoloha khubu.

Li fumaneha ka mefuta e fapaneng ea boholo le boholo ba pore.

3. Lisefe tsa Membrane:

Li-filters tsena li sebelisa li-membrane tse tšesaane tse nang le boholo bo khethehileng ba pore ho lumella limolek'hule tse nyane ho feta masoba

ho feta. Li sebetsa hantle bakeng sa ho tlosa likaroloana tse nyane haholo, ho kenyeletsoa libaktheria, livaerase,

le limolek'hule tse qhibilihisitsoeng.

Mefuta ea Lisefe tsa Membrane:

* Microfiltration:

pore boholo ba 0.1 ho 10 microns 'me li sebelisetsoa ho tlosa libaktheria, likokoana-hloko le likaroloana tse ling tse kholo.

* Ultrafiltration:

pore boholo ba 0.01 ho 0.1 microns 'me li sebelisetsoa ho tlosa likokoana-hloko, liprotheine le likaroloana tse ling tse nyenyane.

* Nanofiltration:

pore boholo ba 0.001 ho 0.01 microns 'me li sebelisetsoa ho tlosa limolek'hule tse qhibilihisitsoeng joalo ka letsoai le tsoekere.

* Fetola osmosis:

tse nyane ka ho fetisisa tsa li-filters tsa membrane (0.0001 microns) 'me li sebelisetsoa ho tlosa hoo e batlang e le.

limolek'hule tsohle tse qhibilihisitsoeng ho tsoa metsing.

Lisebelisoa tsa ho Filtration ea Liquid:

* Phekolo ea metsi:

Ho tlosa litšila metsing a nooang, ho hloekisa metsi a litšila.

* Ho sebetsana le lik'hemik'hale:

Ho arola li-reactants, lihlahisoa, le li-catalyst nakong ea liphetoho tsa lik'hemik'hale.

* Indasteri ea lijo le lino:

Ho hlakisa le ho hloekisa lino, ho tlosa lintho tse tiileng ho oli,le ho arola likarolo

ts'ebetsong ea lijo.

* Tlhahiso ea meriana:

Ho hloekisa meriana le ho hloekisa lihlahisoa tsa likokoana-hloko.

* Ho sebetsa ha oli le khase:

Ho arola metsi le litšila tse ling ho oli le khase.

Ho khetha theknoloji e nepahetseng ea ho hloekisa metsi ho itšetlehile ka lintlha tse 'maloa, ho kenyelletsa:

* Boholo le mofuta oa likaroloana tse lokelang ho tlosoa

* Boemo bo lakatsehang ba bohloeki

* Sekhahla sa phallo ea mokelikeli

* Ho tsamaellana ha lik'hemik'hale tsa mokelikeli le lintho tse sefang

* Theko le ho rarahana ha tšebetso

Kahoo ho bohlokoa ho buisana le setsebi se tšoanelehang sa ho sefa ho fumana mofuta o nepahetseng oa sefe bakeng sa hau

ditlhoko tse itseng.

Ligase tse Khethehileng le Ho Hloekisa Mekelikeli e Khethehileng

Ho sefa ha likhase tse khethehileng le lino ho hlahisa mathata a ikhethang ka lebaka la thepa ea tsona e kotsi,

litlhoko tse phahameng tsa bohloeki, kapa lihlopha tse rarahaneng. Mona ke karohano ea mathata le

litharollo tse amehang:

Mathata:

* Likhase le lino tse senyang kapa tse sebetsang:

Tsena li ka senya lisebelisoa tsa setso tsa filthara, tse hlokang lisebelisoa tse ikhethang joalo ka Hastelloy kapa PTFE.

* Litlhoko tse phahameng tsa bohloeki:

Liindastering tse kang tsa meriana le li-semiconductors, esita le lits'ila li ka khona haholo

tšusumetso boleng ba sehlahisoa.

Ho fihlella le ho boloka maemo a phahameng joalo a bohloeki ho hloka mekhoa e thata ea ho sefa.

* Liqapi tse rarahaneng:

Mekelikeli e meng e na le likarolo tse ngata tse nang le boholo bo fapaneng le thepa,

ho etsa hore karohano le tlhoekiso di be thata ho feta.

Litharollo:

* Lisebelisoa tse khethehileng:

Lisefe tse entsoeng ka thepa e hananang le ho bola joalo ka lialloi tsa tšepe, lipolima tse kang PTFE (Teflon), kapa lirafshoa

e ka mamella lik'hemik'hale tse bohale le tikoloho e mabifi.

* Mekhoa e matla ea ho sefa:

Mekhoa e kang ho hloekisa ka mekhahlelo e mengata, ultrafiltration, le nanofiltration e ka finyella maemo a phahameng a bohloeki.

ka ho tlosa le makumane a manyane le ditshila.

* Meralo e tsoetseng pele ea li-filters:

Lifilimi tsa Membrane tse nang le boholo bo nepahetseng ba pore kapa li-cartridges tse entsoeng ka mokhoa o khethehileng li ka tlosa ka boikhethelo.

likarolo tse itseng tse ipapisitseng le boholo le thepa ea tsona.

* Taolo le ts'ebetso ea ts'ebetso:

Tlhokomelo ea nako ea 'nete ea khatello, sekhahla sa phallo, le maemo a bohloeki li thusa ho netefatsa ts'ebetso e nepahetseng le

ho kena dipakeng ka nako ha ho hlaha diphapang.

* Adsorption le filthara ea lik'hemik'hale:

Maemong ao karohano e rarahaneng e hlokahalang, mekhoa e meng e kang adsorption e kentsoeng

li-filters tsa carbon kapa tsa lik'hemik'hale li ka sebelisoa ho tlosa litšila tse itseng.

Mekhoa e tsoetseng pele ea ho Filtration:

* Chromatography ea Khase:

Ho arola le ho khetholla likarolo tse sa fetoheng ka har'a motsoako oa khase ho sebelisa kholomo e nang le thepa e khethehileng ea adsorbent.

* High-Performance Liquid Chromatography (HPLC):

E sebelisa khatello e phahameng ho arola likarolo tsa metsi ho ipapisitsoe le tšebelisano ea tsona le mohato o emeng.

* Membrane Distillation:

E sebelisa li-membrane ho arola likarolo ho ipapisitsoe le ho feto-fetoha ha tsona, e lumellang karohano e baballang matla ea maro a hloekileng.

* Electrostatic Precipitation:

E sebelisa sebaka sa motlakase ho tjhaja likaroloana, ho li hohela ho bokella lipoleiti le ho li tlosa ka nepo ho tsoa phallong ea khase.

Mehlala ea Ligase tse Khethehileng le Mekelikeli:

* Hydrofluoric acid:

E senya haholo, e hloka li-filters tse khethehileng tsa PTFE.

* Lik'hemik'hale tsa tšebetso ea semiconductor:

Ho hlokahala bohloeki bo phahameng haholo, bo hlokang ho sefa ka mekhahlelo e mengata ka ho beha leihlo ka thata.

* Biopharmaceuticals:

E na le kutloelo-bohloko ho litšila 'me e hloka li-filters tse khethehileng bakeng sa tlhoekiso.

* Likhase tse chefo:

Ho hlokahala li-filters tse khethehileng le mekhoa ea ho sebetsana le mekhoa ea ho etsa bonnete ba polokeho.

Bohlokoa:

Ho sefa likhase le lino tse khethehileng ka katleho ho bohlokoa bakeng sa ho netefatsa polokeho, boleng le ts'ebetso.

ea mekhoa e fapaneng ho pholletsa le liindasteri. Ho sefa ka tsela e fosahetseng ho ka lebisa tšilafalong ea sehlahisoa,

tshenyo ya thepa, dikotsi tsa polokeho, le dikotsi tsa tikoloho.

Ho Hloekisa Mocheso o Phahameng le Khatello e Phahameng ea Likhase

Mocheso o phahameng oa mocheso le khatello e phahameng (HTHP) ea ho hloekisa khase e baka mathata a ikhethang ka lebaka la ho feteletseng

maemo a hlokang moralo o ikgethileng le ho nahanoa ka thepa.

Mona ke kakaretso ea likarolo tsa bohlokoa:

Lintlha tsa Moralo:

* Khatello ea ho hanyetsa:

Sefa matlo le likarolo li tlameha ho mamella khatello e kholo ntle le deformation kapa ho phatloha.

* Mamello ea mocheso:

Lisebelisoa li hloka ho boloka matla le botšepehi ba tsona mochesong o phahameng ntle le ho qhibiliha kapa ho theola seriti.

* Corrosion resistance:

Likarolo tsa filthara li tlameha ho hana ho bola ho tsoa khase e itseng e sefuoang.

* Phallo e sebetsang hantle:

Moralo o hloka ho fokotsa ho theoha ha khatello ha o ntse o boloka ts'ebetso e phahameng ea ho sefa.

* Bohloeki le nchafatso:

Li-filters tse ling li hloka ho hloekisoa kapa ho nchafatsoa ho boloka ts'ebetso, 'me moralo o lokela ho lumellana le lits'ebetso tsena.

Lintlha tsa bohlokoa:

* Metal alloys:

Litšepe tse sa hloekang, Hastelloy, le Inconel ke likhetho tse tloaelehileng ka lebaka la matla a tsona a phahameng, ho hanyetsa mocheso le ho hanyetsa ho bola.

* Ceramics:

Alumina, zirconia, le silicon carbide li loketse mocheso o phahameng haholo 'me li fana ka khanyetso e ntle ea lik'hemik'hale.

* Likhoele tsa khalase:

Lithapo tsa khalase tsa borosilicate li fana ka ho hanyetsa mocheso o phahameng le katleho e ntle ea ho hloekisa.

* Li-polymer tse khethehileng:

PTFE le li-polymer tse ling tse sebetsang hantle haholo li ka sebelisoa bakeng sa lits'ebetso tse ikhethileng tse hlokang khanyetso ea lik'hemik'hale le ho fetoha habonolo.

Lintlafatso tsa Theknoloji:

Ho hlahile mahlale a macha a 'maloa ho rarolla mathata a tlhoekiso ea khase ea HTHP:

* Lintho tsa sefahla sa ceramic:

Tsena li fana ka khanyetso e phahameng ea mocheso (ho fihla ho 1800 ° C) 'me li ka etsoa ka boholo bo itseng ba pore

ho fihlella tshebetso e lakatsehang ya ho tlhotla.

E entsoe ka li-porous metal powders, li-filters tsena li fana ka matla a phahameng, ho hanyetsa mocheso o motle,

mme e ka hlwekiswa le ho ntjhafatswa ka bokgabane.

* Lifilimi tsa ho itlhoekisa:

Tsena li kenyelletsa mekhoa e kang ho phunya ka morao kapa ho phalla ho khutlela morao ho tlosa ka bo eona

litšila, ho fokotsa litlhoko tsa tlhokomelo.

* Lifilimi tsa Membrane:

Li-membrane tse hanyetsanang le mocheso o phahameng tse nang le boholo bo nepahetseng ba pore li ka sebelisoa bakeng sa katleho e phahameng

ho tlhotla likarolo tse itseng tsa khase.

Mehlala ea Lisefe tsa HTHP:

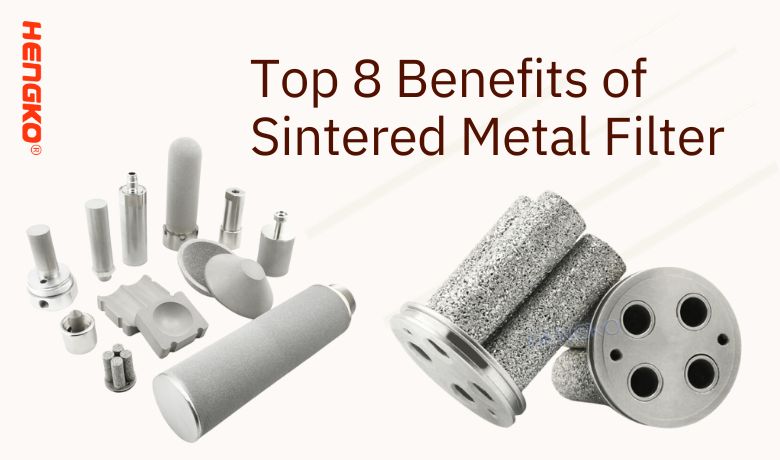

- Sintered metal filters:

- Lintho tsa Sesefa sa Ceramic:

- Lisefa tsa membrane tsa mocheso o phahameng:

Lisebelisoa:

Ho hloekisa khase ea HTHP ho bohlokoa liindastering tse fapaneng:

* Ho hlahisa matla:

Ho tlosa lintho tse itseng ho tsoa moeeng o kenang oa turbine ho sireletsa li-turbine le ho ntlafatsa ts'ebetso.

* Ho sebetsana le lik'hemik'hale:

Ho sefa likhase tse chesang le mouoane ka liphetoho tsa lik'hemik'hale ho tlosa litšila le ho netefatsa boleng ba sehlahisoa.

* Indasteri ea peterole:

Ho arola likarolo tsa khase ho tloha lits'ebetsong tsa ho hloekisa le ho sebetsa.

* Indasteri ea tšepe le tšepe:

Ho sefa likhase tse chesang tse tsoang liboping le licheso ho laola tšilafalo ea moea.

* Sepakapaka:

Ho sireletsa lisebelisoa tse hlokolosi ho tsoa leroleng le litšila libakeng tse nang le mocheso o phahameng.

Qetello:

Mocheso o phahameng le khatello e phahameng ea khase e hloekisang e hloka moralo o hlokolosi le khetho ea

lisebelisoa ho netefatsa ts'ebetso e sireletsehileng le e sebetsang.

Ka ho utloisisa mathata le ho sebelisa theknoloji e tsoetseng pele, liindasteri li ka atleha

sefa likhase tsa HTHP bakeng sa lits'ebetso tse fapaneng,ho kenya letsoho ntlafatsong ea ts'ebetso, tikoloho

tshireletso, le polokeho ya tshebetso.

Mocheso o Phahameng le ho Hloekisa Liquids tsa Khatello e Phahameng

Mekelikeli ea mocheso o phahameng le khatello e phahameng (HTHP) e hlahisa mathata a ikhethang bakeng sa ho sefa ka lebaka la

maemo a feteletseng a ka amang tshebetso haholo.

Mona ke kakaretso ea mathata le litharollo tsa bohlokoa:

Mathata:

* Liphetoho tsa viscosity:

Ha mocheso o ntse o eketseha, viscosity ea lino e fokotseha, e leng ho nolofalletsang lintho tse ling tse silafatsang

ho feta sefeneng.

* Katoloso ea mocheso:

Likarolo tsa mokelikeli le filthara li atoloha ka lebelo le fapaneng ka lebaka la liphetoho tsa mocheso, mohlomong

e amang tshebetso ya ho tlhotla le ho baka ho dutla.

* Litlamorao tsa khatello:

Khatello e phahameng e ka kopanya mecha ea litaba, ea fokotsa porosity le katleho ea eona. Ho feta moo,

e ka baka khatello ea maikutlo holim'a matlo a filthara le litiiso, tse lebisang ho hloleheng ho ka bang teng.

* Tšebelisano ea lik'hemik'hale:

Lithempereichara tse phahameng le likhatello li ka eketsa ts'ebetso ea lik'hemik'hale ea mokelikeli, e hlokang ho khethehileng

lisebelisoa bakeng sa filthara ho netefatsa botšepehi ba eona le ho thibela tšilafalo.

* Corrosion:

Motsoako oa mocheso o phahameng, khatello, le maro a ka 'nang a senya li ka potlakisa ho bola

ea likarolo tsa sefe, ho fokotsa nako ea bophelo ba bona le ho beha ts'ebetso ea bona kotsing.

Litharollo le Mekhoa:

Ho hlola mathata ana, ho sebelisoa litharollo le mekhoa e mengata ho HTHP filthara ea metsi:

* Mecha ea litaba ea filthara e khethehileng:

Lisebelisoa tse hanyetsanang le mocheso o phahameng joalo ka letlooeng la tšepe e sa hloekang, phofo ea tšepe e kentsoeng, le ceramic

likhoele li sebelisoa ho mamella maemo a feteletseng.

* Filtration ea mekhahlelo e mengata:

Ho kenya ts'ebetsong li-filters tse ngata tse nang le boholo bo fapaneng ba pore ho ka sebetsana le boholo bo fapaneng ba likaroloana le ho finyella

bokgabane bo phahameng ka kakaretso.

* Taolo ea mocheso:

Ho boloka mocheso o tsitsitseng nakong eohle ea ho hloekisa ho thusa ho fokotsa liphello tsa mocheso

ho atolosoa le ho fetoha ha viscosity.

* Matlo a hananang le khatello:

Matlo a matla a entsoeng ka thepa ea matla a phahameng joalo ka tšepe e sa hloekang kapa titanium e etselitsoe ho

mamella khatello e phahameng le ho thibela ho dutla.

* Litiiso tse hanyetsanang le lik'hemik'hale:

Litiiso tse khethehileng tse entsoeng ka thepa e kang Teflon kapa Viton li sebelisoa ho netefatsa hore li lumellana le

mokelikeli o itseng le ho thibela ho dutla le ha mocheso le kgatello di phahame.

* Lifilimi tsa ho itlhoekisa:

Tsena li kenyelletsa mekhoa e kang ho phunya ka morao kapa ho phalla ka morao ho tlosa litšila tse bokelletsoeng

ka tsela e iketsang, ho fokotsa litlhoko tsa tlhokomelo le ho netefatsa ts'ebetso e tsitsitseng.

Mehlala ea HTHP Liquid Filters:

* Li-filters tsa tšepe tse sirelelitsoeng:

* Lintho tsa sefahla sa ceramic:

* Lifilimi tsa tšepe tsa tšepe:

* Lifilimi tsa membrane tsa mocheso o phahameng:

Lisebelisoa:

HTHP filthara ea metsi e bapala karolo ea bohlokoa liindasteri tse fapaneng:

* Ho sebetsana le lik'hemik'hale:

Ho arola likarolo tse amanang le lik'hemik'hale, ho hloekisa lintho tse tiileng le litšila.

* Indasteri ea peterole:

Ho lokisa oli e tala le khase ea tlhaho, ho sefa litšila pele ho ts'ebetso e tsoelang pele.

* Ho hlahisa matla:

Ho hloekisa mouoane le metsi ka har'a li-boilers le li-turbine ho ntlafatsa ts'ebetso le ho thibela tšenyo ea lisebelisoa.

* Indasteri ea tšepe le tšepe:

Ho sefa litšepe tse qhibilihisitsoeng le li-alloys ho tlosa litšila le ho finyella thepa e lakatsehang.

* Indasteri ea lijo le lino:

Ho thibela metsi le ho tlosa litšila ho netefatsa polokeho le boleng ba sehlahisoa.

Qetello:

Ho sefa metsi a mocheso o phahameng le a khatello e phahameng ho hloka theknoloji e khethehileng le ka hloko

ho nahanela maemo a feteletseng a amehang. Ka ho kenya ts'ebetsong litharollo le mekhoa e nepahetseng,

HTHP filtration e ka etsoa ka katleho liindastering tse fapaneng, ho netefatsa boleng ba sehlahisoa, polokeho, le

bokgabane ba tshebetso.

'Me qetellong, re thathamisa tlhokahalo e khethehileng ea khase le metsi ho etsa filtration

Ligase tse Khethehileng le Liquids tse Hlokang Sefello ho Tlhahiso ea Liindasteri

Ligase tse Khethehileng:

* Hydrofluoric acid (HF):

E senya haholo lisebelisoa tse ngata, e hlokang li-filters tse khethehileng tse entsoeng ka Teflon (PTFE) kapa tse ling.

li-polymer tse hanyetsanang.

* Silane (SiH4):

E tukang haholo ebile e le pyrophoric, e hlokang mekhoa e khethehileng ea ho sebetsana le li-filters tse etselitsoeng

ts'ebetso e bolokehileng.

Chlorine (Cl2):

E chefo ebile e senya, e hloka lisebelisoa tse khethehileng joalo ka Hastelloy kapa Inconel bakeng sa lihloela le lisebelisoa tsa ho sebetsana.

Amonia (NH3):

E chefo ebile e senya, e hlokang lihloela tse entsoeng ka tšepe e sa hloekang kapa lisebelisoa tse ling tse manganga.

Hydrogen sulfide (H2S):

E chefo haholo ebile e ka cha, e hloka li-filters tse khethehileng le mehato ea tšireletso.

Sulfur dioxide (SO2):

E senya ebile e chefo, e hlokang lihloela tse entsoeng ka tšepe e sa jeleng paate kapa lisebelisoa tse ling tse hanyetsanang.

Liquid tse Khethehileng:

* Lik'hemik'hale tse hloekileng haholo:

E sebelisoa indastering ea semiconductor le ea meriana, e hlokang maemo a holimo haholo a bohloeki le

li-filters tse khethehileng tse kang li-membrane filters kapa li-multi-stage filtration systems.

* Biopharmaceuticals:

E baballa litšila 'me e hloka lihloela tse khethehileng tse etselitsoeng tlhoekiso le ho netefatsa boleng ba sehlahisoa.

* Litšepe tse qhibilihisitsoeng le lialloys:

Lithempereichara tse phahameng le monyetla oa ho tiisa li hloka li-filters tse khethehileng tse entsoeng ka thepa ea refractory joalo ka

li-ceramics kapa li-alloys tsa mocheso o phahameng.

* Matsoai a qhibilihisitsoeng:

E senya haholo 'me e hloka lisebelisoa tse khethehileng tse kang Hastelloy kapa Inconel bakeng sa li-filters le lisebelisoa tsa ho tšoara.

* Li-slurries le li-pastes:

Viscosity e phahameng le tlhaho ea abrasive e hloka meralo e khethehileng ea filthara le lisebelisoa ho netefatsa ho sefa hantle

le ho thibela ho koala.

* Mekelikeli e chefo le e kotsi:

E hloka mekhoa e khethehileng ea ho sebetsana le li-filters tse etselitsoeng ho thibela ho lutla le ho pepesehela lintho tse kotsi.

Hlokomela:

Lena ha se lethathamo le felletseng, 'me mofuta o ikhethileng oa khase e khethehileng kapa mokelikeli o hlokang ho hloekisoa o tla ipapisa le

mokhoa o khethehileng oa tlhahiso ea indasteri.

O na le Morero o Khethehileng oa ho Filtration ea Khase kapa Mokelikeli?

HENGKO utloisisa hore phephetso e 'ngoe le e' ngoe ea ho sefa e ikhethile, haholo ha ho tluoa tabeng ea ho sebetsana ka mokhoa o khethehileng

likhase le maro. Boitseanape ba rona ba ho etsa li-filters ho fihlela litlhoko tse ikhethileng bo re khetholla indastering.

Haeba u hloka litharollo tse khethehileng tsa ho sefa, re mona ho u thusa. Hore na ke ea ts'ebeliso e ikhethang

kapa tikoloho e phephetsang, sehlopha sa rona se hlomeletsoe ho rala le ho etsa lihloela tse kopanang le uena

hantle ditlhoko.

Se ke oa lumella mathata a ho sefa hore a u fokolise. Ikopanye le rona bakeng sa OEM (Moetsi oa Lisebelisoa tsa Pele)

litšebeletso tse etselitsoeng litlhoko tse khethehileng tsa morero oa hau.

Ikopanye le rona kajeno hoka@hengko.com ho buisana ka morero oa hau le hore na re ka u thusa joang ho phethahatsa maikutlo a hau.

Re ikemiseditse ho fana ka filthara ya maemo a hodimo, e itlhophilenglitharollo tse u thusang ho fumana liphetho tse nepahetseng.

Nako ea poso: Dec-08-2023