Li-discs tsa tšepe tse nang le li-porous, tse khetholloang ke sebopeho sa tsona sa pore tse hokahaneng, li hlahile e le lisebelisoa tsa phetoho tse nang le mefuta e mengata ea likopo. Li-discs tsena, tse entsoeng ka litšepe tse fapaneng, li fana ka motsoako o ikhethang oa thepa e etsang hore e be ea bohlokoa haholo liindastering tse fapaneng. Bohlokoa ba tsona bo ho bokhoni ba tsona ba ho ipabola ka ho sefa, ho ajoa ha mokelikeli, le ho hasana ha khase, ha li ntse li boloka nako e telele le botsitso tlas'a maemo a feteletseng.

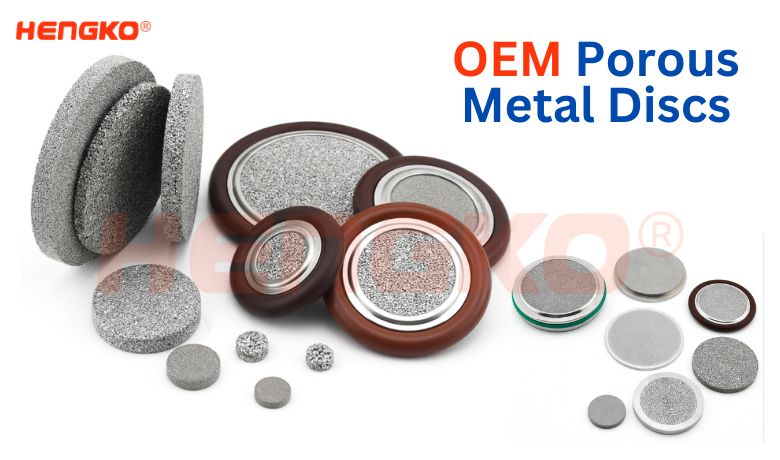

Li-Porous Metal Discs: Ho Shebella ho Fetoha ha Tsona

Li-discs tsa tšepe tsa porous li entsoe ka mekhoa e fapaneng, ho kenyelletsa le sintering, etching, le electrospinning. Ts'ebetso tsena li lumella taolo e nepahetseng holim'a boholo ba pore le kabo, e nolofalletsang tlhophiso ea thepa ea disc hore e lumellane le lits'ebetso tse ikhethileng. Porosity, ho tloha ho 30% ho ea ho 90%, e etsa qeto ea ho khona ha disc, ho susumetsa bokhoni ba eona ba ho sefa kapa ho aba maro le likhase.

Tlhahlobo e Bapisang: Li-Porous Metal Discs khahlano le Lisebelisoa tsa Setso

Ho ananela bohlokoa baporousli-disc tsa tšepe, a re li bapise le lisebelisoa tsa setso tse sebelisoang liindastering tse fapaneng.

Tlhophiso

Sebakeng sa ho sefa, li-discs tsa tšepe tse nang le porous li hlahella ka katleho ea tsona e phahameng le ho tšoarella. Sebopeho sa tsona se rarahaneng sa pore se tšoasa litšila ka nepo e makatsang, esita le maemong a submicron. Ho feta moo, ho hanyetsa ha bona ho kutu le mocheso o phahameng ho etsa hore e be sebaka se loketseng tikolohong e thata. Ha ho bapisoa le li-filters tsa pampiri kapa tsa polymer, li-discs tsa tšepe tse nang le porous li fana ka nako e telele ea bophelo le litšenyehelo tse fokotsehileng tsa tlhokomelo.

Kabo ea Mokelikeli

Li-discs tsa tšepe tsa porous li ipabola lits'ebetsong tsa kabo ea mokelikeli, ho netefatsa phallo e ts'oanang le ho thibela mocha. Pore geometry ea bona e laoloang e lumella taolo e nepahetseng holim'a sekhahla sa phallo le kabo ea khatello. Sena se li etsa hore li tšoanelehe bakeng sa lits'ebetso tsa ts'ebetso ea lik'hemik'hale, meriana, le sebaka sa sefofane, moo ho tsamaisoa ha metsi ho leng bohlokoa. Lisebelisoa tsa setso tse kang lipoleiti tse nang le perforated kapa meshes ea terata hangata li sokola ho fihlela boemo bo ts'oanang ba ho nepahala le ho tsitsa.

Phallo ea Khase

Li-porous metal discs li bapala karolo ea bohlokoa ts'ebelisong ea khase, ho thusa phapanyetsano e ntle ea khase le ho khothaletsa tšebetso ea lik'hemik'hale. Pore ea bona e phahameng le sebopeho sa pore se hokahaneng se fokotsa ho hanyetsa ho ata, ho lumella likhase hore li kenelle ka har'a disc ka potlako. Sena se etsa hore e be likarolo tsa bohlokoa liseleng tsa mafura, libeteri le lisensara tsa khase, moo matla a phallo ea khase e leng a bohlokoa haholo. Lisebelisoa tsa setso tse kang li-ceramics tsa porous kapa lifilimi tsa polymer hangata li bonts'a matla a tlase a khase le botsitso bo fokolang tlas'a khatello e phahameng kapa maemo a mocheso.

Qetello: Li-Porous Metal Discs - Boitsebiso ba Bokamoso

Li-discs tsa tšepe tse nang le porousli itlhomme ka thata joalo ka thepa ea bohlokoa, li fetola liindasteri tse fapaneng ka motsoako oa tsona o ikhethang oa thepa. Bokhoni ba bona bo phahameng ba ho sefa, kabo e ikhethang ea mokelikeli, le phallo e ntle ea khase li etsa hore e be tsa bohlokoa haholo bakeng sa lits'ebetso tse fapaneng. Ha tsoelo-pele ea thekenoloji le lits'ebetso tse ncha li hlaha, li-porous metal discs li mothating oa ho bapala karolo ea bohlokoa le ho feta ho bopeng bokamoso ba boenjiniere le tlhahiso.

1. Ho Utloisisa Li-Porous Metal Discs

1.1 Tlhaloso ea Porous Metal Discs

Li-discs tsa tšepe tsa porous ke sehlopha sa lisebelisoa tse entsoeng ka boenjiniere tse khetholloang ke marang-rang a tsona a hokahaneng a pores. Li-pores tsena, ho tloha ka boholo ho tloha ho li-micrometer ho ea ho limilimithara, li lumella marotholi le likhase tse laoloang ha li ntse li sefa litšila ka katleho. Li-discs tsa tšepe tse nang le porous li atisa ho etsoa ka tšepe e kang tšepe e sa hloekang, boronse le nickel, e fanang ka motsoako oa matla, ho tšoarella le ho hanyetsa ho bola.

1.2 Mekhoa ea Tlhahiso ea Li-porous Metal Discs

Ho sebelisoa mekhoa e mengata ho etsa li-disc tsa tšepe tse porous, e 'ngoe le e 'ngoe e na le melemo le mefokolo ea eona. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa:

1. Sintering: Sintering e kenyelletsa ho hatella phofo ea tšepe hore e be sebopeho se lakatsehang ebe e futhumatsa mocheso o ka tlase ho ntlha ea ho qhibiliha. Ts'ebetso ena e lumella likaroloana tsa tšepe hore li kopane, ho theha sebopeho sa porous.

2. Etching: Etching e kenyelletsa ho khetha ho tlosa thepa ho tloha karolong e ka tlaase ea tšepe ho etsa li-pores. Mokhoa ona o fana ka taolo e nepahetseng holim'a boholo ba pore le kabo.

3. Electrospinning: Electrospinning e sebelisa sebaka sa motlakase ho hula likhoele tse ntle ho tsoa motsoako oa polymer. Likhoele tsena li ka basinteredkapa se kopantsweng mmoho ho etsa diski e tshepe e porous.

1.3 Melemo ea Porous Metal Discs

Li-discs tsa tšepe tse nang le porousfana ka melemo e mengata ho feta lisebelisoa tsa setso tse kang pampiri, polymer, kapa lifilthara tsa ceramic:

1. Katleho e Phahameng ea Filtration: Li-discs tsa tšepe tse nang le porous li ka hloekisa ka katleho litšila tse nyenyane haholo, ho ea ho li-submicron.

3. Reusability le Sustainability: Li-discs tsa tšepe tse porous li ka hloekisoa le ho sebelisoa hape ka makhetlo a mangata, ho fokotsa tšusumetso ea tikoloho.

4. Ho feto-fetoha ha maemo le ho Customization: Li-discs tsa tšepe tse porous li ka etsoa ho latela boholo ba pore, porosity, le sebopeho sa thepa ho lumellana le lits'ebetso tse itseng.

5. Biocompatibility: Li-discs tse ling tsa tšepe tse nang le porous li na le biocompatible, li etsa hore li tšoanelehe bakeng sa lisebelisoa tsa bongaka le tsa meriana.

2. Mefuta e mengata ea li-Porous Metal Discs ?

Li-discs tsa tšepe tsa porous li arotsoe ho latela boholo ba pore, porosity le sebopeho sa thepa.

Mona ke mefuta e meng e tsebahalang haholo:

1. Sintered Porous Metal Discs:

Li-discs tsena li entsoe ka phofo ea tšepe ea sintering ka mocheso o phahameng.

Li-discs tse hlahisoang li na le boholo ba pore le ho ajoa, ho li etsa

e loketseng bakeng sa lits'ebetso tsa filtration.

2. Etched Porous Metal Discs:

Li-discs tsena li entsoe ka ho khabisa paterone letlapeng le tiileng la tšepe.

Mokhoa ona o lumella ho laola ka nepo boholo ba pore le sebopeho,

ho etsa hore di lokele dikopo

moo ho hlokehang ho nepahala ho phahameng.

3. Electrospun Porous Metal Discs:

Li-discs tsena li entsoe ka electrospinning tharollo ea nanoparticles ea tšepe holim'a substrate.

Li-discs tse hlahisoang li na le porosity e phahameng haholo le sebopeho sa pore se sa tloaelehang, se etsang hore se tšoanelehe

bakeng sa lits'ebetso moo phallo ea khase e leng bohlokoa.

4. Li-Pad Porous Metal Discs:

Li-discs tsena li na le gradient ea boholo ba pore ho tloha holimo ho ea kahare.

Sekhahla sena se lumella ho sefa ho eketsehileng, kaha likaroloana tse kholoanyane li qabeletsoe

bokantle bo bokantle

le likaroloana tse nyane li qabeletsoe ka hare ho bokaholimo.

5. Multilayer Porous Metal Discs:

Li-discs tsena li entsoe ka ho beha li-discs tse 'maloa tsa boholo bo fapaneng ba pore hammoho.

Sena se lumella hore ho thehoe mekhoa e rarahaneng ea ho hloekisa e ka tlosang bophara

mefuta e mengata ea litšila.

6. Wicking Porous Metal Discs:

Li-discs tsena li etselitsoe ho khantša maro ka har'a li-pores.

Sena se etsa hore li be molemo bakeng sa likopo moo ho leng bohlokoa ho

abela maro ka ho lekana,

joalo ka liseleng tsa mafura le libeteri.

7. Li-Porous Metal Discs bakeng sa Likopo tsa Biomedical:

Li-discs tsena li entsoe ka thepa e lumellanang le biocompatible, joalo ka titanium le tšepe e sa hloekang.

Li sebelisoa lits'ebetsong tse fapaneng tsa bongaka, joalo ka li-implants tsa masapo le mekhoa ea ho fana ka lithethefatsi.

3. Tlhahlobo e Bapisang le Sesefa sa Tloaelo sa Disc

1. Tshebetso

Li-discs tsa tšepe tsa porous li fana ka melemo e mengata ea ts'ebetso ho feta lisebelisoa tsa setso mabapi le ho tšoarella, bokhoni le ts'ebetso.

| Sebopeho | Li-porous Metal Discs | Lisebelisoa tsa Setso |

|---|---|---|

| Ho tšoarella | Phahameng | Tlase |

| Katleho | Phahameng | E itekanetseng |

| Tshebetso | Phahameng | E itekanetseng |

Li-discs tsa tšepe tsa porous li tšoarella ka mokhoa o makatsang 'me li khona ho mamella maemo a thata, mocheso o phahameng le likhatello tse feteletseng. Sena se etsa hore e be tse loketseng bakeng sa lits'ebetso moo lisebelisoa tsa setso li neng li ka nyenyefatsa kapa tsa hloleha kapele. Ho feta moo, li-porous metal discs li fana ka ts'ebetso e phahameng haholo mabapi le ho sefa, kabo ea mokelikeli le phallo ea khase. Sebopeho sa bona se rarahaneng sa pore se lumella hore ho be le taolo e nepahetseng holim'a likhahla tsa phallo le kabo ea khatello, e leng se lebisang ho ntlafatso ea ts'ebetso mefuteng e mengata ea likopo.

2. Theko-e sebetsang hantle

Le hoja li-discs tsa tšepe tse nang le li-porous li ka 'na tsa e-ba le litšenyehelo tse phahameng tsa pele ha li bapisoa le thepa ea setso, litšenyehelo tsa bona tsa nako e telele hangata li phahametse. Ho tšoarella ha tsona le ho sebelisoa hape ho fokotsa tlhoko ea ho nchafatsoa khafetsa, 'me litlhoko tsa bona tse tlase tsa tlhokomelo li fokotsa litšenyehelo tsa ts'ebetso.

| Sebopeho | Li-porous Metal Discs | Lisebelisoa tsa Setso |

|---|---|---|

| Litšenyehelo tsa Pele | E itekanetseng | Tlase |

| Litšenyehelo tsa Tlhokomelo | Tlase | E itekanetseng |

| Lipolokelo tsa nako e telele | Phahameng | E itekanetseng |

Ha nako e ntse e ea, chelete ea ho boloka litšenyehelo tse fokotsehileng tsa tlhokomelo le lits'enyehelo tse ncha li ka feta matsete a holimo a pele ho li-discs tsa tšepe tsa porous. Sena se etsa hore e be tharollo e theko e tlaase bakeng sa likopo moo ho ts'epahala le ts'ebetso ea nako e telele e leng tsa bohlokoa.

3.Phello ea Tikoloho

Li-discs tsa tšepe tsa porous li fana ka melemo e mengata ea tikoloho ho feta lisebelisoa tsa setso. Ho tšoarella ha tsona le ho sebelisoa hape ho fokotsa tlhahiso ea litšila, 'me bokhoni ba tsona ba ho sebelisoa hape bo fokotsa sebaka sa bona sa tikoloho. Ho phaella moo, li-discs tsa tšepe tsa porous li ka sebelisoa ho etsa lihlahisoa tse tsitsitseng haholoanyane, tse kang lisele tsa mafura le libeteri, tse tlatsetsang bokamoso bo botala.

| Sebopeho | Li-porous Metal Discs | Lisebelisoa tsa Setso |

|---|---|---|

| Moshoelella | Phahameng | Tlase |

Li-discs tsa tšepe tsa porous ke khetho e tsitsitseng ea thepa e ka thusang ho fokotsa tšusumetso ea tikoloho le ho khothalletsa moruo o chitja haholoanyane. Ho tšoarella ha tsona, ho sebetsa hape, le ho sebelisoa hape ho li etsa khetho e nang le boikarabelo tikolohong bakeng sa lits'ebetso tse fapaneng.

Qetellong, li-discs tsa tšepe tsa porous li fana ka motsoako o qobellang oa ts'ebetso, ts'ebetso ea litšenyehelo, le ts'ebetso ea tikoloho. Ho tšoarella ha bona ho holimo, ho sebetsa hantle, le ts'ebetso ea bona e ba etsa khetho e nepahetseng bakeng sa lits'ebetso tse batlang, athe poloko ea bona ea nako e telele ea litšenyehelo le melemo ea tikoloho e ba etsa letsete le tsitsitseng. Ha tsoelo-pele ea theknoloji le lits'ebetso tse ncha li hlaha, li-disc tsa tšepe tse porous li se li loketse ho bapala karolo ea bohlokoa le ho feta ho bopeng bokamoso ba boenjiniere le tlhahiso.

4. Likopo le Lipapiso tse Ikemetseng tsa Indasteri

Sepakapaka

Li-porous metal discs li bapala karolo ea bohlokoa lits'ebetsong tsa sepakapaka, haholo lits'ebetsong tsa filtration le likarolo tsa enjine. Bokhoni ba tsona ba ho mamella mocheso o feteletseng, likhatello, le ho thothomela ho etsa hore e be tse loketseng tikolohong ena e boima.

Sistimi ea ho Filtration

Li-discs tsa tšepe tsa porous li sebelisoa mekhoeng e fapaneng ea ho sefa ho pholletsa le lifofane, ho kenyelletsa:

*Tlhahiso ea Mafura:

Likarolo tsa Enjene

Li-discs tsa tšepe tsa porous li boetse li sebelisoa likarolong tse sa tšoaneng tsa enjene, ho akarelletsa:

* Li-Liner tsa Combustor:

Tsa makoloi

Li-discs tsa tšepe tsa porous li fumana lits'ebetso tse ngata indastering ea likoloi, haholo-holo lits'ebetsong tsa ho ntša metsi le ho sefa.

Sistimi ea Exhaust

* Liphetoho tsa Catalytic:

* Li-mufflers:

Tlhophiso

-

*Air Filtration: Porous metal discs filter moea o kenang enjeneng, o thibela tšilafalo ea likarolo tse hlokolosi le ho netefatsa ts'ebetso e nepahetseng ea enjine.

-

* Filtration ea oli: Ba sefa oli ea enjine, ba tlosa litšila le ho netefatsa hore likarolo tsa enjine li tlotsoa ka nepo.

Tšebeliso ea Lik'hemik'hale

Li-discs tsa tšepe tsa porous li phetha karolo ea bohlokoa ts'ebetsong ea lik'hemik'hale, haholo-holo ho catalysis le mekhoa ea karohano.

Catalysis

-

* Litšehetso tsa Catalyst: Li-discs tsa tšepe tse nang le porous li fana ka sebaka se phahameng bakeng sa li-catalysts, tse nolofalletsang lik'hemik'hale tse sebetsang hantle. Li khothaletsa kabo e tšoanang ea likaroloana tsa catalyst le ho ntlafatsa phetisetso ea bongata lipakeng tsa li-reactants le li-catalyst.

-

Li-Reactors tsa Bed-Fixed: Li sebetsa e le thepa ea ho paka ka har'a li-reactor tse nang le bethe e tsitsitseng, tse tsamaisang puisano e laoloang pakeng tsa li-reactants le li-catalyst. Sebopeho sa bona sa pore se ts'oanang se netefatsa phallo e nepahetseng le katleho ea karabelo.

Mekhoa ea ho arohana

-

* Filtration: Li-porous metal discs li sebelisoa mekhoeng ea ho hloekisa ho tlosa litšila lihlahisoa tse fapaneng tsa lik'hemik'hale. Boholo ba bona bo laoloang ba pore bo lumella karohano e khethehileng ea lintho tse tiileng ho tsoa ho metsi.

-

* Karohano ea Membrane: Li sebelisoa mekhoeng ea karohano ea lera, joalo ka phallo ea khase le mouoane. Sebopeho sa bona sa porous se lumella karohano e khethehileng ea likhase kapa metsi ho latela thepa ea bona ea limolek'hule.

Lisebelisoa tsa Bongaka

Li-discs tsa tšepe tse nang le porous li fumane botumo bo botle lits'ebetsong tsa lisebelisoa tsa bongaka, haholo-holo ho li-implants le tsamaiso ea filtration.

Li-implants

-

* Li-implants tsa Lesapo: Li-discs tsa tšepe tse porous li sebelisoa ho kenngoa ha masapo, joalo ka li-implants tsa masapo le li-implants tsa meno. Sebopeho sa bona sa porous se khothalletsa ho kenngoa ha masapo le ho kopanya ha masapo, ho netefatsa botsitso le ts'ebetso ea nako e telele.

-

* Li-Scaffolds tsa Boenjiniere ba Tissue: Li sebetsa e le scaffolds bakeng sa boenjiniere ba lisele, ho fana ka moralo o tšehetsang kholo ea lisele le tsosoloso ea lisele. Sebopeho sa tsona sa porous se lumella ho kenella ha lisele le ho hasana ha limatlafatsi, ho khothalletsa ho thehoa ha lisele.

Sistimi ea ho Filtration

*Tlhahiso ea Mali:

*Sistimi ea phepelo ea lithethefatsi:

Likarolo tsa Sintered Porous Metal Discs

| Sebopeho | Boleng |

|---|---|

| Lintho tse bonahalang | Tšepe e se nang tšepe, boronse, nickel |

| Mokhoa oa ho Etsa | Sintering |

| Boholo ba Pore | Li-micrometer ho isa ho limilimithara |

| Porosity | 30% ho isa ho 90% |

| Melemo | Ho tšoarella ho hoholo, ho sebetsa hantle le ho sebetsa; Reusability; Biocompatibility (bakeng sa lisebelisoa tse itseng) |

| Mefokolo | Litšenyehelo tse phahameng tsa pele ha li bapisoa le thepa ea setso |

Sintered porous metal discs e ntse e ata ka ho eketsehileng ka likopo tsa indasteri ka lebaka la

thepa ea bona e ikhethang le melemo.

Li entsoe ka sintering tšepe phofo ka mocheso o phahameng, e leng se bōpa e porous sebopeho le

pore e lekanang le boholo le kabo.

Sebopeho sena se li etsa hore li tšoanelehe bakeng sa lits'ebetso tse fapaneng, ho kenyelletsa:

* Filtration:

Sintered porous metal discs e ka sebelisoa ho sefa mefuta e mengata ea maro, ho kenyelletsa le maro, likhase le li-slurries.

Li sebetsa hantle ho tloseng lintho tse silafatsang marong ana, e leng se etsang hore e be tse loketseng ho sebelisoa indastering

ditsamaiso tse hlokang maemo a hodimo a bohloeki.

* Kabo ea metsi:

Sintered porous metal discs e ka sebelisoa ho arola metsi ka mokhoa o lekanang ka holim'a metsi.

Sena se etsa hore e be tse loketseng lits'ebetso tse joalo ka lisele tsa mafura le libeteri,

moo ho leng bohlokoa ho aba maro ka ho lekana ho eketsa ts'ebetso.

* Phetiso ea mocheso:

Sintered porous metal discs e ka sebelisoa ho fetisa mocheso ho tloha holim'a metsi ho ea ho o mong.

Li sebetsa hantle ha li tsamaisa mocheso, li etsa hore e be tse loketseng lits'ebetso tse kang li-heaters le licheso tsa mocheso.

Ntle le thepa ea bona e sebetsang, li-discs tsa tšepe tse sintered li boetse li fana ka tse 'maloa

melemo ho feta lisebelisoa tsa setso, joalo ka:

* Ho tšoarella ho phahameng:

Sintered porous metal discs ba nako e telele haholo le ka mamella maemo a thata.

Li khona ho mamella ho bola, khoholeho le ho senyeha ha tsona.

Bothata bo le bong feela bo boholo ba li-disc tsa sintered porous metal ke litšenyehelo tsa bona tsa pele tse phahameng ha li bapisoa le thepa ea setso. Leha ho le joalo, ho boloka litšenyehelo tsa bona tsa nako e telele, ka lebaka la ho sebelisoa hape le ho tšoarella ha bona, ho ka fokotsa litšenyehelo tsena tsa pele.

Ka kakaretso, li-discs tsa tšepe tse sintered porous ke lisebelisoa tse tenyetsehang le tsa bohlokoa tse ka sebelisoang mefuteng e mengata ea lits'ebetso tsa indasteri. Mehaho le melemo ea bona e ikhethang e ba etsa khetho e nepahetseng bakeng sa lits'ebetso tse hlokang nako e telele, bokhoni le ts'ebetso.

Lithuto le Mehlala ea 'Nete ea Lefatše

mona ho na le liphuputso tse qaqileng tse totobatsang katleho ea li-disc tsa porous metal lits'ebetsong tse ikhethileng, hammoho le papiso le maemo ao lisebelisoa tsa setso li sebelisitsoeng maemong a tšoanang:

Thuto-pale 1: Tlhophiso ea Lisele Tsa Mafura

Bothata: Liseleng tsa peterole, litšila tsa khase li ka koala li-electrode le ho fokotsa ts'ebetso. Lisefe tsa khale tsa pampiri li sebelisoa hangata ho tlosa litšila tsena, empa li ka koaleha kapele, 'me li hloka ho nkeloa sebaka khafetsa.

Tharollo: Li-porous metal discs li ka sebelisoa ho sefa phallo ea khase liseleng tsa mafura. Pore ea bona e phahameng le boholo bo laoloang ba pore bo ba lumella ho tlosa litšila ka katleho ntle le ho fokotsa haholo phallo ea khase. Ho phaella moo, li-porous metal discs li tšoarella haholo 'me li ka mamella tikoloho e thata ea sele ea mafura.

Liphello: Tšebeliso ea li-porous metal discs liseleng tsa mafura li lebisitse ho ntlafatso e kholo ea katleho le ho fokotsa litšenyehelo tsa tlhokomelo. Phuputsong e 'ngoe, tšebeliso ea li-discs tsa tšepe tse nang le porous e ile ea eketsa katleho ea lisele tsa mafura ka 10% le ho fokotsa litšenyehelo tsa tlhokomelo ka 50%.

Papiso: Ha ho bapisoa le li-filters tse tloaelehileng tsa pampiri, li-discs tsa tšepe tse porous li fana ka melemo e mengata. Li tšoarella nako e telele, li sebetsa hantle, 'me ha li hloke ho nkeloa sebaka khafetsa. Sena se etsa hore e be tharollo e bolokang chelete e ngata bakeng sa ho hloekisa lisele tsa mafura.

Thuto-pale ea 2: Li-Mufflers tsa Exhaust System

Bothata: Li-mufflers tsa setso tsa khale li sebelisa fiberglass kapa boea ba ceramic e le thepa e monyang molumo. Leha ho le joalo, lisebelisoa tsena li ka senyeha ha nako e ntse e ea 'me tsa se ke tsa sebetsa hantle. Ho feta moo, e ka ba kotsi ea mollo.

Tharollo: Li-discs tsa tšepe tse nang le porous li ka sebelisoa e le lisebelisoa tse monyang molumo ka har'a li-mufflers tsa sistimi. Sebopeho sa tsona se nang le masoba ka katleho se monya le ho qhala maqhubu a molumo. Ho phaella moo, li-discs tsa tšepe tsa porous li tšoarella haholo 'me li khona ho mamella mocheso o phahameng le likhatello tsa tsamaiso ea ho qeta nako.

Liphello: Tšebeliso ea li-discs tsa tšepe tse nang le porous ho li-mufflers tsa tsamaiso ea exhaust li lebisitse ho fokotseha ho hoholo ha lerata. Phuputsong e 'ngoe, tšebeliso ea li-porous metal discs e ile ea fokotsa tlhahiso ea lerata ho fihla ho 10 dB.

Papiso: Ha ho bapisoa le lisebelisoa tsa setso tse monyang molumo, li-discs tsa tšepe tse porous li fana ka melemo e mengata. Li tšoarella nako e telele, li sebetsa hantle haholo ho fokotsa ho ntšoa ha lerata, 'me ha li na kotsi ea mollo. Sena se etsa hore e be tharollo e lakatsehang haholoanyane bakeng sa li-mufflers tsa sistimi ea ho khathala.

Thuto-pale ea 3: Ho Sefa Mali ho Hemodialysis

Bothata: Ka hemodialysis, mali a tšeloa ka sefeng ho ntša litšila. Lisefe tsa setso tsa dialysis hangata li sebelisa li-membrane tsa cellulose joalo ka lintho tse sefang. Leha ho le joalo, li-membrane tsa cellulose li ka tšoaetsoa habonolo 'me ho ka ba thata ho li hloekisa.

Tharollo: Li-discs tsa tšepe tse nang le porous li ka sebelisoa e le lintho tse sefang ka har'a li-filters tsa hemodialysis. Bongata ba tsona bo laoloang ba pore bo li lumella ho khetha ho tlosa litšila tse tsoang maling ha li ntse li boloka likarolo tsa bohlokoa tsa mali. Ho phaella moo, li-discs tsa tšepe tse porous li tšoarella haholo 'me li ka hloekisoa habonolo.

Liphello: Tšebeliso ea li-discs tsa tšepe tse nang le porous ho li-filters tsa hemodialysis li lebisitse ho ntlafatso e kholo ea boleng ba phekolo ea dialysis. Phuputsong e 'ngoe, tšebeliso ea li-porous metal discs e fokolitse maemo a litšila maling ho fihlela ho 50%.

Papiso: Ha ho bapisoa le li-membrane tsa setso tsa cellulose, li-discs tsa tšepe tse porous li fana ka melemo e mengata. Li tšoarella nako e telele, li sebetsa hantle ho tlosa litšila, 'me li ka hloekisoa habonolo. Sena se etsa hore e be tharollo e lakatsehang haholoanyane bakeng sa li-filters tsa hemodialysis.

Lithuto tsena li bonts'a katleho ea li-discs tsa tšepe tse nang le porous lits'ebetsong tse fapaneng. Lintho tsa bona tse ikhethang le melemo e ba etsa thepa ea bohlokoa bakeng sa mefuta e mengata ea liindasteri le likopo tsa bongaka.

Ke tšepa hore boitsebiso bona bo thusa. Ke kopa u ntsebise haeba u na le lipotso tse ling.

Kakaretso ea Liphuputso tsa Bohlokoa ho Tsoa Tlhahlobo ea Papiso

Patlisiso ea rona lefats'eng la li-porous metal discs e senotse lintlha tse 'maloa tsa bohlokoa. Haholo-holo, li-discs tsa tšepe tse nang le porous li fana ka melemo e ikhethang ho feta lisebelisoa tsa setso liindastering tse fapaneng ka lebaka la ho tšoarella ha tsona, ho sebetsa hantle le ho sebetsa. Mabapi le ts'ebetso, li-discs tsena li hlahella libakeng tse thata, tse fanang ka nako e telele ea bophelo le ho hanyetsa maemo a feteletseng. Katleho ea litšenyehelo ke sebaka se seng moo li-discs tsa tšepe tsa porous li khanyang, ho fana ka polokelo ea nako e telele ho sa tsotellehe litšenyehelo tse phahameng tsa pele. Ho feta moo, tšusumetso ea bona ea tikoloho ha e mpe haholo, e tsamaellana hantle le tlhoko e ntseng e hola ea mekhoa e tsitsitseng ea indasteri.

Mehopolo ea ho Qetela ka Karolo ea Porous Metal Discs ho Likopo tsa Indasteri

Li-discs tsa tšepe tsa porous hase likarolo feela; li fetola likarolo tsa ts'ebeliso ea indasteri. Ho tloha sebakeng sa sefofane ho ea ho lisebelisoa tsa bongaka, li-discs tsena li beha litekanyetso tse ncha tsa ts'ebetso le ho tšepahala. Ho ikamahanya le maemo le ho sebetsa hantle ha bona ho li etsa hore li tšoanelehe bakeng sa lits'ebetso tse fapaneng, ho bonts'a phetoho e kholo tseleng eo liindasteri li atamelang khetho ea thepa le moralo. Ha thekenoloji e ntse e tsoela pele, re ka lebella ho kopanngoa ho hoholo le ho feta ha li-disk tsa tšepe tsa porous ho li-application tse ncha le tse ncha, ho tiisa bohlokoa ba tsona sebakeng sa indasteri.

A na u na le mehopolo mabapi le ts'ebeliso ea nako e tlang ea li-porous metal discs?

Na u kile ua kopana le liphephetso kapa katleho e ikhethang ea ho li sebelisa ka har'a indasteri ea hau?

Mohlomong u na le lipotso mabapi le thepa ea bona, mekhoa ea tlhahiso, kapa linyeoe tse khethehileng tsa tšebeliso?

Ke u khothaletsa ho arolelana lipale tsa hau, lipotso le lintlha tsa hau le rona.

Ka kopo ikopanye le uena ka lengolo-tsoibila hoka@hengko.com.

Maikutlo a hau ha a amohelehe feela; ho bohlokoa bakeng sa ho atolosa puisano ea rona le ho tebisa tsebo ea rona

mabapi le likarolo tsena tse feto-fetohang le tsa bohlokoa indastering ea sejoale-joale.

Nako ea poso: Nov-17-2023