Likhoele, li-spirals tse rarahaneng tse fumanoang liboutung, likurufung le ka har’a linate, li rarahane ho feta kamoo li hlahang kateng. Li fapana ka moetso, boholo, le tšebetso, li bopa tsela eo likarolo li kopanang ka eona nthong e ’ngoe le e ’ngoe ho tloha ka mechine e bonolo ho ea ho litsamaiso tse tsoetseng pele tsa boenjiniere. Tataisong ena, re hlahloba lintlha tsa motheo tsa moralo oa likhoele, re hlahloba lintlha tsa motheo tse khethollang khoele e 'ngoe ho e' ngoe. Ho tloha ho bong ba likhoele ho ea ho matsoho a tsona, le ho tloha ho bophahamo ba tsona ho isa bophara ba tsona, re sibolla lintlha tsa bohlokoa tse etsang hore likhoele e be mohlolo o hlollang oa boenjiniere empa hangata o hlokomolohuoa.

Sheba lintlha tse latelang ha re ntse re manolla lefats'e le rarahaneng la likhoele, ho u fa kutloisiso ea motheo ea bohlokoa bakeng sa moithuti ea qalang ho tseba le setsebi se nang le boiphihlelo.

Mantsoe a mang a bohlokoa a Thread

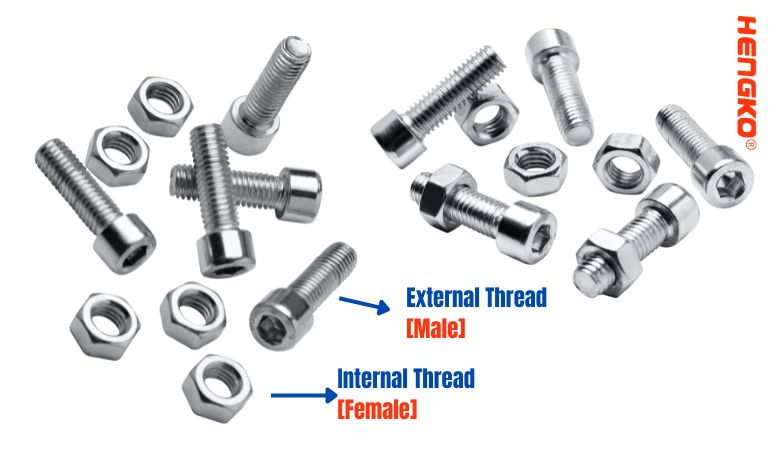

Ho sebelisa mantsoe a bong ho ka ntšetsa pele likhopolo tse kotsi le ho kenya letsoho moetlong oa ho ikarola. Ka ho sebelisa mantsoe a sa nke lehlakore joalo ka likhoele tsa "ka ntle" le "ka hare", re ka kenyelletsa bohle le ho qoba leeme le sa reroang.

* Ho nepahala:Papiso e senyeha ho ea pele ha ho nahanoa ka liforomo tsa khoele tse seng tsa binary le likopo.

Ho bohlokoa ho nepahala le ho kenyelletsa puong ea tekheniki hape.

* Mekhoa e meng:Ho na le mantsoe a tekheniki a hlakileng le a thehiloeng hantle bakeng sa litšobotsi tsa khoele:

* Likhoele tsa kantle:Likhoele bokantle ba motsoako.

* Likhoele tsa ka hare:Likhoele ka hare ho motsoako.

* Bophara bo boholo:Bophara bo boholo ba khoele.

* Bophara bo bonyenyane:Bophara bo bonyenyane ka ho fetisisa ba khoele.

* Sekhahla:Sebaka pakeng tsa lintlha tse peli tse tsamaellanang holim'a likhoele tse bapileng.

Ho sebelisa mantsoe ana ho fana ka boitsebiso bo nepahetseng le bo hlakileng ntle le ho itšetleha ka lipapiso tse ka bang kotsi.

Likhoele li sebelisoa ho kopanya li-filters

Li-filters tse sintered li sebelisoa haholo liindastering tse fapaneng molemong oa ho sefa. Li entsoe ka ho kopanya li-powders tsa tšepe hammoho ka mokhoa oa ho phekola mocheso o bitsoang sintering. Sena se etsa hore ho be le sebopeho se matla, se nang le masoba se khonang ho sefa likaroloana tsa maro kapa likhase.

Hangata likhoele li sebelisoa ka har'a li-filters ho kopanya likarolo tse fapaneng. Mehlala ke ena e tobileng ea hore na likhoele li sebelisoa joang likopanong tsa sintered filter:

* Filter cartridge end caps:

Likhatriji tse ngata tsa sintered filter li na le li-end caps tse li lumellang hore li kenngoe ka har'a matlo a sefa.

Sena se etsa tiiso e sireletsehileng le ho thibela ho lutla.

* Sefa likhokahano tsa matlo:

Hangata matlo a li-filters a na le likou tse nang le likhoele tse li lumellang hore li hokahane le liphaephe kapa lisebelisoa tse ling.

Sena se lumella ho kenya habonolo le ho tlosoa ha kopano ea filthara.

* Li-filters tsa pele:

Li-filters tse ling li sebelisa li-pre-filters ho tlosa likaroloana tse kholo pele li fihla ho sintered filter.

Li-pre-filters tsena li ka 'na tsa phunyeletsoa sebakeng sa tsona ho sebelisoa likhoele.

* Likou tsa drainage:

Mehaho e meng ea li-filters e na le likou tsa drainage tse lumellang ho ntšoa ha maro a bokeletsoeng kapa likhase.

Mofuta o itseng oa khoele o sebelisoang kopanong ea filthara o tla ipapisa le ts'ebeliso le boholo ba sefe. Mefuta e tloaelehileng ea likhoele e kenyelletsa NPT, BSP, le Metric.

Ntle le mehlala e kaholimo, likhoele le tsona li ka sebelisoa molemong oa ho kopanya li-filters tsa sintered, joalo ka:

* Ho hokela li-sensor kapa li-gauge

* Li-brackets tse hokahaneng

* Ho sireletsa likarolo tsa ka hare

Ka kakaretso, likhoele li bapala karolo ea bohlokoa ho netefatsa ts'ebetso e nepahetseng le ts'ebetso ea likopano tsa sintered filter.

Qetellong, khetho ea mantsoe e ho uena.

Leha ho le joalo, ke u khothalletsa hore u nahane ka tšusumetso e ka bang teng ea ho sebelisa puo ea bong le melemo ea ho sebelisa mekhoa e meng e sa nke lehlakore le e kenyeletsang.

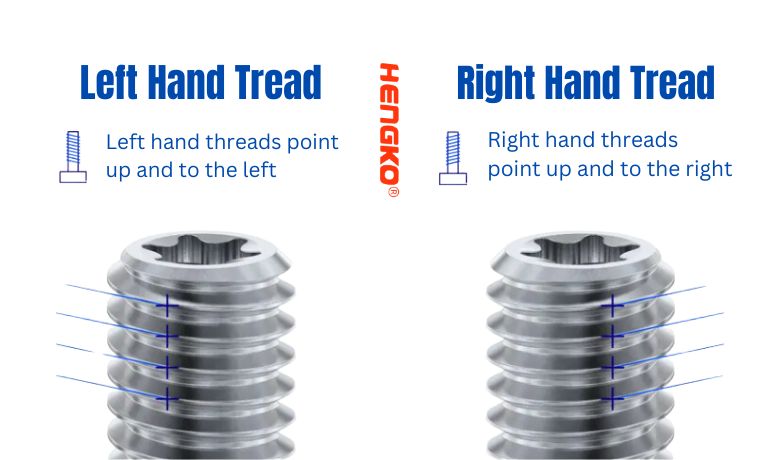

Handed of Threads

Ke hobane'ng ha likhoele tse ka letsohong le letona li atile haholo?

* Ha ho na lebaka le hlakileng la histori, empa likhopolo-taba tse ling li fana ka maikutlo a hore e ka ba ka lebaka la leeme la tlhaho la batho ba bangata ba ho sebelisa letsoho le letona, ho etsa hore ho be bonolo ho tiisa le ho lokolla likhoele tse letsohong le letona ka letsoho la bona le ka sehloohong.

* Likhoele tse ka letsohong le letona le tsona li na le tšekamelo ea ho itlama ha li le tlas'a matla a ho potoloha ka tsela e tšoanang le ea ho tiisa (mohlala, boutu lebiling le ohiang).

Lisebelisoa tsa likhoele tse ka letsohong le letšehali:

Joalo ka ha u boletse, likhoele tse ka letsohong le letšehali hangata li sebelisoa maemong ao ho thothomelang ka lebaka la ho thothomela kapa matla a ho potoloha,

joalo ka: Li boetse li sebelisoa lisebelisoa le lisebelisoa tse ikhethileng moo ho hlokahalang tataiso e fapaneng ea ho potoloha bakeng sa ts'ebetso.

* Libotlolo tsa khase: Ho thibela ho buleha ka phoso ka lebaka la khatello ea kantle.

* Libaesekele tsa Pedal: Ka lehlakoreng le letšehali ho li thibela ho theoloha ka lebaka la ho potoloha ha lebili.

* Tšitiso e ea lekana: Ho theha e tiileng haholoanyane, e sireletsehileng haholoanyane e hananang le ho qhaqhoa.

Ho tsebahatsa thread handedness:

* Ka nako e 'ngoe tataiso ea khoele e tšoauoa ka ho toba ho fastener (mohlala, "LH" bakeng sa letsoho le letšehali).

* Ho shebella angle ea likhoele ho tloha lehlakoreng ho ka boela ha senola tsela:

1.Likhoele tse ka letsohong le letona li thellela holimo ho ea ka ho le letona (joaloka sekurufu se nyolohelang thabeng).

2. Likhoele tse ka letsohong le letšehali li theohela holimo ho le letšehali.

Bohlokoa ba ho fana ka li-filters tse sintered le ts'ebeliso e tloaelehileng.

Matsoho, ha a bua ka tsela eo likhoele li potolohang ka eona (ho ea ka nako ea oache kapa ho ea ka lebelo la oache), ehlile e bohlokoa lits'ebetsong tsa sintered filter ka mabaka a 'maloa:

Thibelo ea ho Tiisa le ho Dutla:

* Ho tiisa le ho lokoloha: Ho fana ka letsoho ka nepo ho tiisa hore likaroloana li tiisa ka mokhoa o sireletsehileng ha li fetisetsoa ka lehlakoreng le reriloeng 'me li lokolloha habonolo ha ho hlokahala. Likhoele tse sa lumellaneng li ka lebisa ho tiiseng ho feta tekano, ho senya sefe kapa ntlo, kapa ho tiisa ho sa fellang, ho bakang ho lutla.

* Ho bososela le ho hapa: Tataiso e fosahetseng ea likhoele e ka baka likhohlano le khohlano, ea etsa hore ho be thata kapa ho se khonehe ho arola likarolo. Sena se ka ba bothata haholo nakong ea tlhokomelo kapa ho nkela filthara sebaka.

Maemo le Tumellano:

- Ho fapanyetsana: Ho fana ka khoele e tloaelehileng ho lumella hore ho be bonolo ho nkela lintho tse sefang sebaka kapa matlo a nang le likarolo tse lumellanang, ho sa natsoe moetsi. Sena se nolofatsa tlhokomelo le ho fokotsa litšenyehelo.

- Melao ea Indasteri: Liindasteri tse ngata li na le melaoana e tobileng mabapi le ho fana ka likhoele lits'ebetsong tsa ho sebetsana le mokelikeli ka mabaka a polokeho le ts'ebetso. Ho sebelisa likhoele tse sa lumellaneng ho ka tlōla melao le ho lebisa likotsing tsa polokeho.

Tšebeliso e Tloaelehileng le Matsoho:

- Filter Cartridge End Caps: Ka tloaelo sebelisa likhoele tse letsohong le letona (ho tiisa oache ho tiisa) bakeng sa sehokelo se sireletsehileng ho sefa matlo.

- Filter Housing Connections: Ka kakaretso latela maemo a indasteri, ao hangata a hlalosang likhoele tse ka letsohong le letona bakeng sa likhokahano tsa liphaephe.

- Pre-filters: E ka sebelisa likhoele tse ka letsohong le letona kapa le letšehali ho latela moralo o itseng le tataiso e reriloeng ea phallo ea mokelikeli.

- Li-Drainage Ports: Hangata li na le likhoele tse ka letsohong le letona hore li bulehe habonolo le ho koala ho ntša maro.

Kea ts'epa hore tlhaiso-leseling ena e ka u thusa ho utloisisa lintlha tsa ho fana ka khoele!

Moqapi oa Khoele

Ka bobeli likhoele tse bapileng le tse tapered li phetha karolo ea bohlokoa lits'ebetsong tse fapaneng, e 'ngoe le e' ngoe e na le melemo le ts'ebeliso ea eona e ikhethang. Ho eketsa botebo ba tlhaloso ea hau, lintlha tse ling tseo u ka li nahanang ke tsena:

1. Mekhoa ea ho Tiisa:

* Likhoele tse tšoanang:

Ka kakaretso ba itšetleha ka litiiso tse kantle joalo ka li-gaskets kapa li-O-rings bakeng sa likhokahano tse sa lutseng.

Sena se lumella ho kopanya khafetsa le ho qhaqha ntle le ho senya likhoele.

* Likhoele tse Tapered:

Ba theha khokahanyo e tiileng, e itihelang ka lebaka la ketso ea ho nyalana ha ba ntse ba phunyeletsoa.

Sena se etsa hore e be tse loketseng bakeng sa lits'ebetso tsa khatello e phahameng joalo ka liphaephe le li-fittings.

Leha ho le joalo, ho tiisa ho feta tekano ho ka senya likhoele kapa tsa etsa hore ho be thata ho li ntša.

2. Maemo a Tloaelehileng:

* Likhoele tse tšoanang:

Tsena li kenyelletsa maemo a kang Unified Thread Standard (UTS) le likhoele tsa Metric ISO.

Li tloaelehile lits'ebetsong tse akaretsang tse kang liboutu, likurufu le linate.

* Likhoele tse Tapered:

Khoele ea Naha ea Pipe (NPT) le Khoele e Tloaelehileng ea Pipe ea Borithane (BSPT)

li sebelisoa haholo lits'ebetsong tsa matla a lipeipi le metsi.

Lisebelisoa:

* Likhoele Tse Tšoanang: E sebelisoa ho kopanya thepa ea ka tlung, lisebelisoa tsa elektroniki, mechini le lits'ebetso tse ling tse fapaneng moo ho hlokahalang ho qhaqhoa khafetsa le ho tiisa litiiso tse hloekileng.

* Likhoele tse Tapered: E loketse lipeipi tsa metsi, li-hydraulic, sistimi ea moea, le ts'ebeliso efe kapa efe e hlokang khokahanyo ea bopaki ba ho lutla tlas'a khatello kapa vibrate.

Lintlha tse ling:

* Maemo a mang a likhoele joalo ka BSPP (British Standard Pipe Parallel) a kopanya foromo e bapileng le selikalikoe se koalang bakeng sa likhokahano tse sa duleng.

* Bohole ba likhoele (sebaka se pakeng tsa likhoele) le botebo ba likhoele le tsona li bapala karolo ea bohlokoa ho matla le tšebetso ea khoele.

Bohlokoa ba mofuta o mong le o mong oa moralo oa khoele ho li-filters tsa tšepe tse sintered.

Le ha moralo oa likhoele ka boona o se oa tlhaho oa mofuta oa sefe, o bapala karolo ea bohlokoa ts'ebetsong le ts'ebetsong ea likopano tsa sintered metal filter. Mona ke kamoo meralo e fapaneng ea likhoele e amang lihloela tsa tšepe tse sirelelitsoeng:

Meetso e Tloaelehileng ea Khoele:

* NPT (National Pipe Thread): E sebelisoa haholo Amerika Leboea bakeng sa lits'ebetso tse akaretsang tsa liphaephe. E fana ka tiiso e ntle 'me e fumaneha habonolo.

* BSP (British Standard Pipe): E tloaelehile Europe le Asia, e ts'oana le NPT empa ka liphapang tse nyane. Ho bohlokoa ho tsamaisana le maemo a ho lekana hantle.

* Metric Threads: E hlophisitsoe lefatšeng ka bophara, e fana ka likhetho tse pharalletseng tsa likhoele bakeng sa litlhoko tse ikhethang.

* Likhoele tse ling tse Khethehileng: Ho ipapisitsoe le ts'ebeliso, meralo e khethehileng ea likhoele joalo ka SAE (Society of Automotive Engineers) kapa JIS (Maemo a Indasteri a Japane) a ka sebelisoa.

Melemo ea Moralo oa Khoele:

* Thibelo ea ho Tiisa le ho Dutla: Moralo o nepahetseng oa likhoele o tiisa likhokahano tse tiileng, o thibela ho lutla le ho boloka botsitso ba filthara. Likhoele tse sa lumellaneng li ka baka ho lutla, ho sitisa ts'ebetso mme ho ka lebisa likotsing tsa polokeho.

* Kopano le Disassembly: Meralo e fapaneng ea likhoele e fana ka boiketlo bo fapaneng ba ho kopanya le ho qhaqha. Lintlha tse kang sekontiri sa khoele le litlhoko tsa lubrication li hloka ho nahanoa bakeng sa tlhokomelo e nepahetseng.

* Maemo le Tumellano: likhoele tse emeng joalo ka NPT kapa Metric li netefatsa hore li tsamaellana le matlo a tloaelehileng a filthara le sistimi ea lipeipi. Ho sebelisa likhoele tse sa tloaheleheng ho ka baka mathata a ho lumellana 'me ha ba thata ho nkela sebaka.

* Matla le Khatello ea Ts'ebetso: Moralo oa likhoele o susumetsa matla le bokhoni ba ho sebetsana le khatello kopanong ea filthara. Lisebelisoa tsa khatello e phahameng li ka hloka mefuta e itseng ea likhoele e nang le boitlamo bo tebileng bakeng sa kabo e ntle ea mojaro.

Ho Khetha Moqapi o Nepahetseng oa Khoele:

* Litlhoko tsa Kopo: Nahana ka lintlha tse kang khatello ea ts'ebetso, mocheso, tšebelisano ea mokelikeli, le maqhubu a batloang a kopano / a ho qhaqhoa.

* Maemo a Indasteri: Khomarela litekanyetso le melaoana e amehang ea indasteri bakeng sa sebaka sa hau se ikhethileng kapa ts'ebeliso.

* Ho tsamaellana: Etsa bonnete ba hore e tsamaellana ka mokhoa o se nang moeli le matlo a sefang, lisebelisoa tsa lipeipi, le likarolo tse ling tse ka bang teng.

* Tšebeliso e bonolo: Leka-lekanya tlhoko ea tiiso e sireletsehileng ka boiketlo ba ho e lokisa le tse ka bang teng nakong e tlang.

Hopola, leha moralo oa likhoele o sa hokahane ka kotloloho le mofuta oa sefa sa tšepe se sirelelitsoeng, ke ntlha ea bohlokoa bakeng sa ts'ebetso e akaretsang le bots'epehi ba kopano ea sefe. Khetha moralo o nepahetseng oa likhoele o ipapisitse le litlhoko tsa hau tse ikhethileng tsa kopo 'me u nahane ka ho buisana le setsebi sa filtration bakeng sa tataiso.

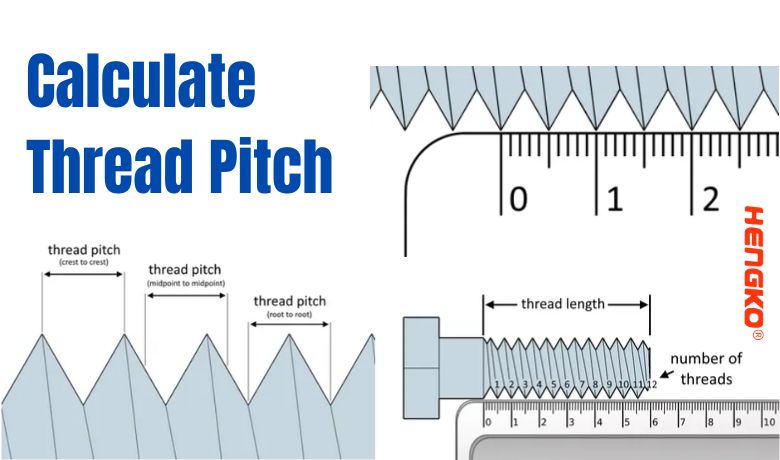

Pitch le TPI

* Pitch: E lekantsoe ka limilimithara, ke sebaka ho tloha khoeleng e 'ngoe ho ea ho e 'ngoe.

* TPI (Threads Per Inch): E sebelisoa bakeng sa likhoele tse boholo ba lisenthimithara, tse bontšang palo ea likhoele ka bolelele ba lisenthimithara.

Kamano lipakeng tsa Pitch le TPI:

* Ha e le hantle li lekanya ntho e le 'ngoe (tekanyo ea likhoele) empa ka liyuniti tse fapaneng le litsamaiso tsa ho metha.

1. TPI ke moelelo oa lentsoe: TPI = 1 / Pitch (mm)

2. Ho sokoloha lipakeng tsa bona ho ea pele:Ho fetolela TPI ho ea ho sekontiri: Pitch (mm) = 1 / TPI

Ho fetolela molumo ho TPI: TPI = 1 / Pitch (mm)

Liphapang tse ka Sehloohong:

* Yuniti ea Tekanyo: Pitch e sebelisa limilimithara (metric system), ha TPI e sebelisa likhoele ka inch (sistimi ea borena).

* Kopo: Pitch e sebelisetsoa li-fasteners tsa metric, ha TPI e sebelisetsoa li-fasteners tse thehiloeng ho inch.

Ho Utloisisa Tekano ea Khoele:

* Bobeli ba molumo le TPI li u bolella kamoo likhoele li pakiloeng ka thata kateng holim'a sekoahelo.

* TPI e tlase kapa e phahameng e bolela likhoele tse ngata ka bolelele ba yuniti, e hlahisang khoele e ntle.

* Likhoele tse ntle ka kakaretso li fana ka:

1. Ho hanyetsa ka matla ho lokoloha ka lebaka la ho thothomela kapa torque.

2. Bokhoni bo ntlafetseng ba ho tiisa ha bo sebelisoa ka lisebelisoa tse loketseng.

3. Ho fokotseha ho fokolang ha likhoele tsa ho kopanya nakong ea kopano le ho qhaqhoa

Leha ho le joalo, likhoele tse ntle li ka boela tsa:

* E-ba kotsing ea ho pharalla kapa ho hlobolisoa ha e sa tsamaellane hantle.

* E hloka matla a mangata ho tiisa le ho theola.

Ho Khetha Tekano e Nepahetseng ea Khoele:

* Ts'ebeliso e ikhethileng le litlhoko tsa eona li khetholla molumo o nepahetseng kapa TPI.

* Lintlha tse kang matla, ho hanyetsa ho sisinyeha, litlhoko tsa ho tiisa, le boiketlo ba kopano / disassembly li lokela ho nkoa.

* Ho shebana le litekanyetso tse nepahetseng le litataiso tsa boenjiniere ho bohlokoa bakeng sa ho khetha tekano e nepahetseng bakeng sa litlhoko tsa hau tse ikhethileng.

Diameter

Likhoele li na le li-diameter tse tharo tsa bohlokoa:

* Major Diameter: Bophara bo boholo ba khoele, bo lekantsoeng ka har'a li-crest.

* Minor Diameter: Bophara bo bonyenyane ka ho fetisisa, bo lekantsoeng metsong.

* Pitch Diameter: Bophara ba khopolo lipakeng tsa bophara bo boholo le bo nyane.

Ho utloisisa Diameter ka 'ngoe:

* Major Diameter: Ena ke ntlha ea bohlokoa bakeng sa ho netefatsa tšebelisano lipakeng tsa likhoele tsa ho nyalana (mohlala, boutu le nate). Li-bolts le linate tse nang le bophara bo boholo bo tšoanang li tla lumellana, ho sa tsotellehe sebopeho sa sekontiri kapa khoele (e bapileng kapa e tapered).

* Minor Diameter: Sena se ama matla a khoele ea ho kopanela. Bophara bo boholo bo nyane bo bonts'a lisebelisoa tse ngata le matla a ka bang teng a phahameng.

* Pitch Diameter: Ena ke bophara bo inahaneloang moo profaele ea khoele e nang le lintho tse lekanang ka holimo le ka tlase. E bapala karolo ea bohlokoa ho baleng matla a likhoele le lisebelisoa tse ling tsa boenjiniere.

Likamano lipakeng tsa Diameter:

* Li-diameter li amana le profil ea khoele le molumo. Maemo a fapaneng a likhoele (mohlala, metric ISO, Unified National Coarse) a na le likamano tse ikhethileng lipakeng tsa li-diameter tsena.

* Bophara ba sekontiri bo ka baloa ho sebelisoa liforomo tse thehiloeng ho li-diameter tse kholo le tse nyane, kapa ho fumanoa litafoleng tsa litšupiso bakeng sa litekanyetso tse itseng tsa khoele.

Bohlokoa ba ho Utloisisa Diameter:

* Ho tseba bophara bo boholo ho bohlokoa bakeng sa ho khetha li-fasteners tse lumellanang.

* Sekhahla se senyenyane se ama matla 'me se ka ba sa bohlokoa bakeng sa lisebelisoa tse khethehileng tse nang le meroalo e phahameng.

* Pitch diameter e bohlokoa bakeng sa lipalo tsa boenjiniere le ho utloisisa thepa ea likhoele.

Lintlha tse Eketsehileng:

* Litekanyetso tse ling tsa likhoele li hlalosa li-diameter tse eketsehileng joalo ka "motso oa bophara" bakeng sa merero e itseng.

* Litlhaloso tsa mamello ea likhoele li etsa qeto ea phapang e lumellehang ho bophara bo bong le bo bong bakeng sa ts'ebetso e nepahetseng.

Ke tšepa hore boitsebiso bona bo tla hlakisa haholoanyane mesebetsi le bohlokoa ba li-diameter tse fapaneng tsa khoele! Ikutloe u lokolohile ho botsa haeba u na le lipotso tse ling hape.

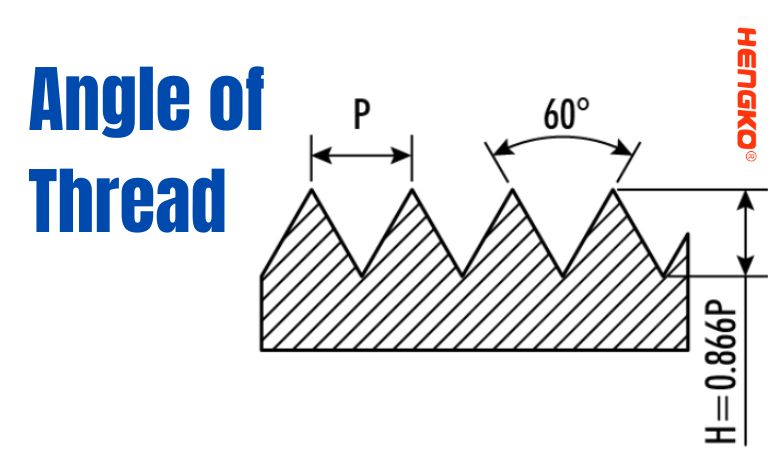

Lenaka

* Flank Angle: Lehlakore le pakeng tsa letlapa la khoele le mola oa perpendicular ho axis.

* Taper Angle: E khethehile ho likhoele tse tapered, ke sebaka se pakeng tsa taper le axis e bohareng.

Flank Angle:

* Ka tloaelo, li-angles tsa mahlakoreng li na le symmetrical (ho bolelang hore mahlakore ka bobeli a na le angle e tšoanang) 'me a lula a le teng ho pholletsa le profil ea khoele.

* The angle flank e atileng haholo ke 60°, e sebelisoang ho latela maemo a kang Unified Thread Standard (UTS) le likhoele tsa Metric ISO.

* Li-angles tse ling tse tloaelehileng tsa flank li kenyelletsa 55° (likhoele tsa Whitworth) le 47.5° (likhoele tsa Mokhatlo oa Brithani).

* Flank angle e ama:**1. Matla: Li-angles tse kholo ka kakaretso li fana ka khanyetso e ntle ea torque empa ha li mamelle ho se tsamaisane hantle.

2. Khohlano: Li-angles tse nyane li etsa hore ho be le likhohlano tse fokolang empa li ka senya bokhoni ba ho its'oara.

3. Sebopeho sa Chip: Flank angle e susumetsa hore na lisebelisoa tsa ho seha li ka etsa likhoele habonolo hakae.

Taper Angle:

* Lehlakore lena le hlalosa lebelo la phetoho ea bophara ho latela khoele e tapered.

* Li-angles tse tloaelehileng tsa taper li kenyelletsa 1:16 (National Pipe Thread - NPT) le 1:19 (British Standard Pipe Thread - BSPT).

* Taper angle e tiisa khokahano e tiileng, e itihelang ha likhoele li hatellana ha li tiisa.

* Ho bohlokoa hore likhoele tse tapered li be le angle e nepahetseng e ts'oanang bakeng sa tiiso e thibelang ho lutla.

Kamano pakeng tsa Angles:

* Likhoeleng tse sa tieang, khutlo e le 'ngoe ke eona feela e amehang.

* Bakeng sa likhoele tse tapered, li-angles tse mahlakoreng le tse taper li bapala karolo:

1. Leqhubu la flank le etsa qeto ea boemo ba khoele ea motheo le thepa e amanang le eona.

2. The angle taper e hlalosa sekhahla sa phetoho ea bophara le ho susumetsa litšobotsi tsa ho tiisa.

Crest le Motso

* Crest: Karolo e ka ntle ea khoele.

* Motso: Karolo e ka hare-hare, e etsang motheo oa sebaka sa khoele.

Ka holimo ho hlalosoa feela mokokotlo le motso oa khoele.

Le hoja libaka tsa bona ka har'a khoele li bonahala li le bonolo, li phetha karolo ea bohlokoa likarolong tse fapaneng tsa ts'ebetso ea khoele le moralo.

Lintlha tse ling tseo u ka li fumanang li le monate ke tsena:

Crest:

*Ena ke ntlha e ka ntle ea khoele, e etsang ntlha ea ho kopana le khoele ea eona ea ho nyallana.

* Matla le botšepehi ba crest li bohlokoa bakeng sa ho jara mojaro o kentsoeng le ho hanela ho roala.

*Tšenyo ea likhoele, li-burrs, kapa ho se phethahale ho ka senya matla le tšebetso ea khokahanyo.

Motso:

*E fumaneha botlaaseng ba khoele, e etsa motheo oa sebaka pakeng tsa likhoele tse bapileng.

*Botebo le sebōpeho sa motso li bohlokoa bakeng sa lintlha tse kang:

1. Matla: Motso o tebileng o fana ka boitsebiso bo bongata bakeng sa ho jara mojaro le matla a ntlafetseng.

2. Tlhokomelo: Ho hlokahala sebaka se lekaneng sa ho tlosa metso ho amohela maloanlahla, litlolo, kapa mefuta e fapaneng ea tlhahiso.

3. Ho tiisa: Mehahong e meng ea likhoele, profil ea motso e kenya letsoho ho tiiseheng ha tiiso.

Kamano pakeng tsa Crest le Root:

*Sebaka se pakeng tsa motso le motso se hlalosa botebo ba khoele, bo amang matla le thepa e 'ngoe ka kotloloho.

*Sebopeho le litekanyo tse ikhethileng tsa crest le motso li ipapisitse le maemo a khoele (mohlala, metric ISO, Unified Coarse) le ts'ebeliso e reriloeng.

Litlhahiso le Lisebelisoa:

*Maemo a likhoele le litlhaloso hangata li hlalosa mamello bakeng sa li-crest le litekanyo tsa metso ho netefatsa ts'ebetso e nepahetseng le ho fapanyetsana.

* Lits'ebetsong tse nang le meroalo e mengata kapa tse senyehileng, li-profiles tse nang le li-crest tse matlafalitsoeng le metso li ka khethoa bakeng sa ho tšoarella ha nako e telele.

* Lits'ebetso tsa tlhahiso le taolo ea boleng li bohlokoa bakeng sa ho netefatsa hore ho na le li-crests tse boreleli, tse se nang tšenyo le metso ho li-fasteners.

Ke ts'epa hore tlhaiso-leseling ena e tla eketsa botebo kutloisisong ea hau ea likarolo le bohlokoa ba crest le motso oa likhoele. Ikutloe u lokolohile ho botsa haeba u na le lipotso tse ling kapa lihlooho tse itseng tse amanang le moralo oa likhoele tseo u ka ratang ho li hlahloba!

Litekanyo tsa Mefuta ea Khoele

Mona ke kakaretso ea mefuta e meng e tloaelehileng eo u e boletseng, hammoho le litšoantšo bakeng sa pono e ntle:

M - ISO Khoele (Metric):

*ISO 724 (DIN 13-1) (Khoele e Mahoashe):

1. Setšoantšo:

2. Sebaka se seholo sa bophara: 3 mm ho ea ho 300 mm

3. Sebaka sa sekhahla: 0.5 mm ho ea ho 6 mm

4. Khoele ea khoele: 60 °

*ISO 724 (DIN 13-2 ho isa ho 11) (Khoele e Ntle):

1. Setšoantšo:

2. Sebaka se seholo sa bophara: 1,6 mm ho ea ho 300 mm

3. Sebaka sa sekhahla: 0.25 mm ho ea ho 3.5 mm

4. Khoele ea khoele: 60 °

NPT - Khoele ea Pipe:

*NPT ANSI B1.20.1:

1. Setšoantšo:

2. Khoele e taped bakeng sa likhokahano tsa liphaephe

3. Sebaka se seholo sa bophara: 1/16 inch ho 27 inches

4. Taper angle: 1:16

*NPTF ANSI B1.20.3:

1. Setšoantšo:

2. E tšoana le NPT empa e na le li-crests tse bataletseng le metso bakeng sa ho tiisa hamolemo

3. Litekanyo tse tšoanang le tsa NPT

G/R/RP - Whitworth Thread (BSPP/BSPT):

*G = BSPP ISO 228 (DIN 259):

1. Setšoantšo:

2. Khoele ea phala e tšoanang

3. Sebaka se seholo sa bophara: 1/8 inch ho 4 inches

4. Khoele ea khoele: 55 °

*R/Rp/Rc = BSPT ISO 7 (DIN 2999 e nketsoe sebaka ke EN10226):

1. Setšoantšo:

2. Khoele ea pipe e tapered

3. Sebaka se seholo sa bophara: 1/8 inch ho 4 inches

4. Aper angle: 1:19

UNC/UNF - Khoele e Kopanetsoeng ea Naha:

*Unified National Coarse (UNC):

1. setšoantšo:

2. E tšoana le M Coarse Thread empa e na le litekanyo tse thehiloeng ho inch

3. Sebaka se seholo sa bophara: 1/4 inch ho 4 inches

4. Likhoele ka inch (TPI) mefuta e fapaneng: 20 ho 1

* Tefiso ea Naha e Kopanetsoeng (UNF):

1. Setšoantšo:

2. E ts'oana le M Fine Thread empa e na le litekanyo tse thehiloeng ho inch

3. Sebaka se seholo sa bophara: 1/4 inch ho 4 inches

4. TPI mefuta e fapaneng: 24 ho 80

Lintlha tse ka holimo li fana ka kakaretso ea kakaretso ea litekanyo tsa mofuta o mong le o mong oa khoele. empa litekanyo tse itseng li ka fapana ho latela maemo le ts'ebeliso e itseng. U ka fumana litafole le litekanyo tse qaqileng litokomaneng tsa maemo a amehang joalo ka ISO 724, ANSI B1.20.1, joalo-joalo.

Ikutloe u lokolohile ho botsa haeba u na le lipotso tse ling kapa u hloka tlhaiso-leseling e batsi ka mefuta e itseng ea likhoele kapa boholo!

SUM

Blog ena re fana ka tataiso e akaretsangmoralo oa khoele, ea bohlokoa bakeng sa ho utloisisa hore na likarolo tsa mochini le litsamaiso tsa boenjiniere li kopana joang.

E akaretsa lintlha tsa mantlha tsa bong ba likhoele, ho tsebahatsa likhoele tsa banna le basali le ts'ebeliso ea tsona ho li-filters tse sintered. hape re hlalosa ho fana ka khoele, ho totobatsa boholo ba likhoele tse ka letsohong le letona lits'ebetsong tse ngata.

Lintlha tse qaqileng li fanoe ka moralo oa likhoele, tse shebaneng le likhoele tse bapisang le tse tapered, le bohlokoa ba tsona ho li-filters tse sintered.

Kahoo tataiso ena ke buka ea bohlokoa ho mang kapa mang ea batlang ho utloisisa ho rarahana ha moralo oa likhoele ho li-filters tse sintered. Leha ho le joalo, ke tšepa hore e tla u thusa

tsebo ea khoele le ho khetha khoele e nepahetseng nakong e tlang, e khethehileng bakeng sa indasteri ea sintered filter.

Nako ea poso: Jan-30-2024