Sintered Metal ke eng?

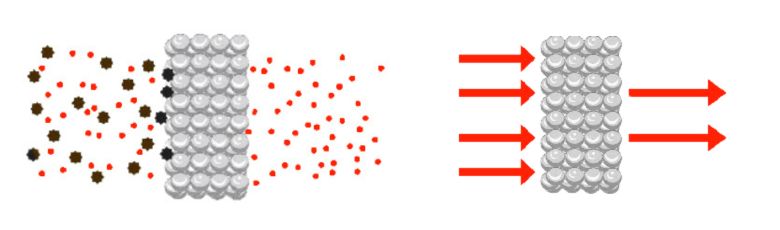

Sintered Filter Working Principle ke Eng?

Ka bokhutšoane ho re, Ka lebaka la foreimi e tsitsitseng ea porous,li-filters tsa tšepe tse sinteredke e 'ngoe ea lintho tse molemo ka ho fetisisa tsa ho hloekisa

mehleng ena. Hape, mocheso o phahameng oa thepa ea tšepe, khatello e phahameng, le ho hanyetsa kutu li ka u thusa

phethela mosebetsi oa ho sefa habonolo sebakeng se thata haholoanyane, Ho arola le ho sefa litšila tse feteletseng

ha u hloke kapa ho u thusa ho ntša likhase tse phahameng tsa bohloeki kapa maro bakeng sa morero oa hau, le haeba u ntse u batla

fektheri e 'ngoe ea' nete ho OEM sintered filthara ea tšepe bakeng sa sistimi ea hau ea ho sefa, ka kopo sheba mona ho fumana

theBaetsi ba Li-filters ba Liindasteri tse ka Sehloohong.

Mohlomong ha ua lokela ho utloa lentsoe lena haholo bophelong ba hau ba letsatsi le letsatsi.

Empa matsatsing ana, tšepe e sintered e sebelisoa haholo indastering e fapaneng, tšepe e sintered e se e qalile ho fetoha.

thetheknoloji ea bohlokoa tlhahisong e itseng.

JoaleHantle-ntle ke Sintered Metal?

Ha e le hantle, ke lekala la indasteri ea phofo ea metallurgy, ka bokhutšoanyane, ke tšepe e sa hloekang ea 316L.phofo ka hlobo

ho bopa, mocheso o phahameng o kenella ka sebopeho le ts'ebetso ea ts'ebetso eo re e hlokang.

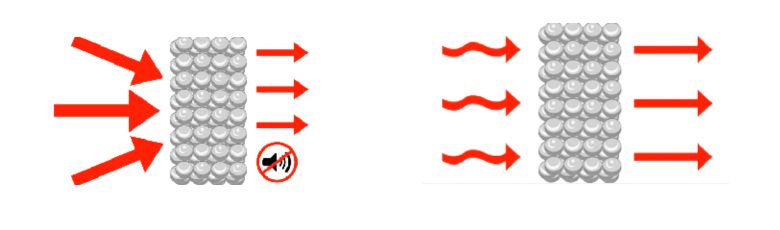

Ebe, Pele, sintered.Sintered ke eng?

Sintering ke mokhoa oa ho kopanyale ho etsa boima bo tiileng bathepa

ka mocheso kapa kgatello ntle le ho qhibidiha ho isa bohodung. Sintering ke karolo eamokhoa oa ho etsa thepa o sebelisoang

ka tšepe, ceramics,polasetiki, le lisebelisoa tse ling.Wikipedia

Joalo ka ha Wikipedia e hlalosa, mefuta e mengata ea lisebelisoa e ka siloa, 'me lihlahisoa tse fapaneng tsa sintered li na le tsona

fapanenglits'ebetso. Joale re rata monaho bua lintlha tse ling mabapi le sintered tšepe.

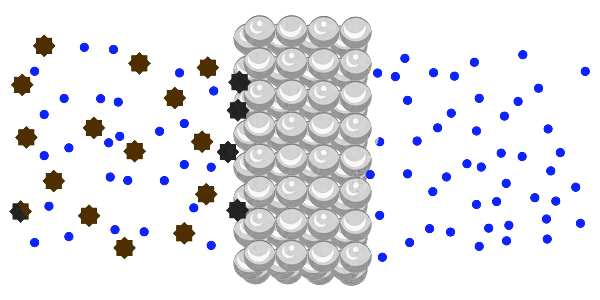

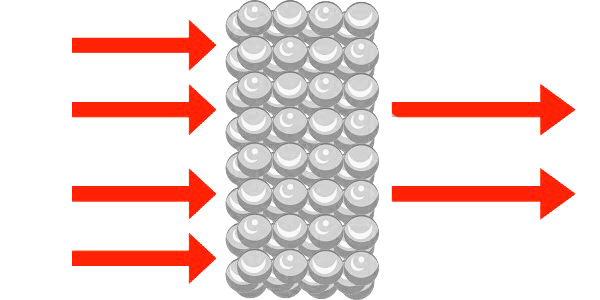

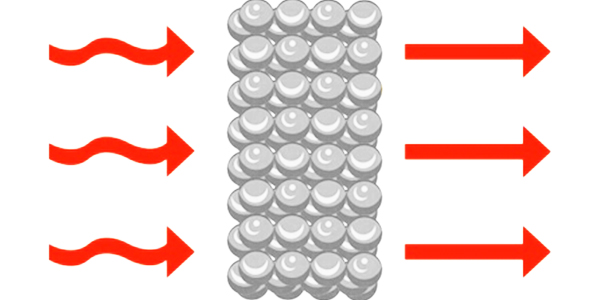

1. Tlhophiso le Karohano 2. Lithibelo tsa mokelikeli

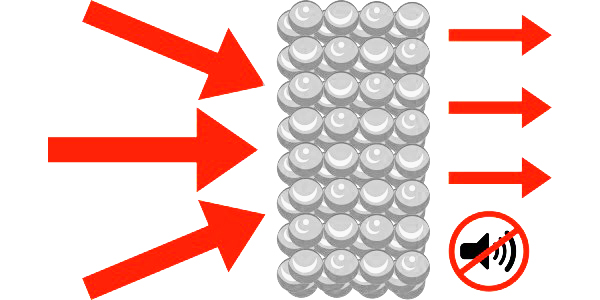

3. Phokotso ea lerata 4. Phallo e tsitsitseng

Historiea Sintering Metal

Ke Bo-mang ba Inventions the sintering mme ba qala ho sebelisa lihlahisoa tsa sintered?

Ho latela litlaleho tsa nalane, ts'ebetso ea sintering e ile ea hlaha nakong ea phetoho ea bobeli ea indasteri lekholong la bo18 la lilemo

naheng ea Sweden le Denmark. Ho ile ha fumanoa tšepe ea sintered nakong ea ho qhibilihisa merafong ea mashala. Empa ho fihlela 1980, batho

ile a qala ho sebelisa sintered tšepe ho oli e tlhotlang. 'Me bakeng sa 1985, theknoloji ea pele e sebelisitseng HyPulse® filtration bakeng sa

tlhoekiso e tsoelang pele ea oli ea seretse.

Kahoo ha e le hantle, o ka sheba ka tsela e latelang, ho na le nako ea mantlha ea 3-ho nts'etsapele.

Kahoo ha e le hantle, o ka sheba ka tsela e latelang, ho na le nako ea mantlha ea 3-ho nts'etsapele.

1.Tšimoloho ea Boholo-holo

*Lilemo tsa Boronse:

Bopaki ba khale ka ho fetesisa ba lits'ebetso tse kang sintering bo qalile mehleng ea Bronze, moo lintho tsa tšepe li neng li le teng

mohlomong e entsoeng ka ho futhumatsa le ho hatella phofo ea tšepe.

*Lilemo tsa tšepe:

Mekhoa ea tšepe, ho kenyelletsa le tšebeliso ea tšepe e futhumetseng le e hatelitsoeng, e ka 'na eaba e kenyelelitsoe

likarolo tsa sintering.

2. Phetohelo ea Liindasteri le Tsoelo-pele ea Pele

* Lekholong la bo19 la lilemo:

Phetohelo ea Liindasteri e ile ea bona thahasello e eketsehileng mekhoeng ea ho sebetsa ka tšepe. Metallurgy ea phofo,

selelekela sa ho sintering, se ile sa qala ho hlaha joalo ka mokhoa oa ho hlahisa lintho tsa tšepe ka thepa ea phofo.

* Mathoasong a lekholo la bo20 la lilemo:

Tsoelo-pele ea mahlale a metallurgy le thepa e lebisitse ho nts'etsopele e eketsehileng ea mekhoa ea sintering.

Tlhahiso ea li-filters tsa tšepe tse porous le li-bearings tse sebelisang mekhoa ea sintering e ile ea e-ba e tloaelehileng haholoanyane.

3.Mehla ea Kajeno le Tsoelo-pele ea Theknoloji

* Bohareng ba lekholo la bo20 la lilemo:

Theknoloji ea Sintering e bile le kholo e kholo bohareng ba lekholo la bo20 la lilemo, e susumetsoang ke tsoelopele

ho metallurgy ea phofo le mahlale a thepa. Ntlafatso ea lisebelisoa tse phahameng tsa sintered bakeng sa

Lisebelisoa tsa lifofane, likoloi, le indasteri e ile ea e-ba tsepamiso.

* Qetellong ea lekholo la bo20 le la bo21 la lilemo:

Qetellong ea lekholo la bo20 la lilemo le mathoasong a lekholo la bo21 la lilemo ho ile ha bona tsoelo-pele e tsoelang pele ea theknoloji ea sintering. Tsoelopele

ea mekhoa e tsoetseng pele ea sintering, joalo ka selective laser sintering (SLS) le binder jetting, e atolositse sebaka.

ya disebediswa le dibopeho tse thata tse ka hlahisoang.

Lisebelisoa tsa Sejoale-joale

*Sekoloi:

Lisebelisoa tsa sintered li sebelisoa haholo likarolong tsa likoloi, ho kenyelletsa le likere, li-bearings le li-filters.

Lintho tsa tsona, tse kang matla, nako e telele, le porosity, li etsa hore e be tse loketseng bakeng sa lisebelisoa tse thata.

*Sepakapaka:

Lisebelisoa tsa sintered li sebelisoa likarolong tsa sefofane ka lebaka la thepa ea tsona e bobebe, e matla haholo.

Li fumaneha likarolong tse kang li-blade tsa turbine, li-nozzles tsa mafura, le li-heaters tsa mocheso.

*Lisebelisoa tsa bongaka:

Lisebelisoa tsa sintered li sebelisoa lisebelisoa tse fapaneng tsa bongaka, ho kenyelletsa le li-implants, li-prosthetics le likarolo tsa meno.

Biocompatibility ea bona le thepa eo u ka e khethang e ba etsa hore ba tšoanelehe bakeng sa lits'ebetso tsena.

* Lisebelisoa tsa indasteri:

Lisebelisoa tsa Sintered li na le lits'ebetso tse ngata tsa indasteri, ho kenyeletsoa ho sefa, lisebelisoa tsa elektroniki le polokelo ea matla.

Litšobotsi tsa bona tse fapaneng le tsa ts'ebetso li etsa hore e be ba bohlokoa liindastering tse fapaneng.

Qetello

Leha ho le joalo, theknoloji ea Sintering e fetohile haholo ho theosa le makholo a lilemo, ho tloha tšimolohong ea eona ea khale ho ea ho ts'ebeliso ea eona ea sejoale-joale.

Ka tsoelopele e tsoelang pele ea mahlale a thepa le lits'ebetso tsa tlhahiso, lisebelisoa tsa sintered li fetohile

likarolo tsa bohlokoa liindasteri tse fapa-fapaneng, tse tlatsetsang tsoelo-peleng ea theknoloji le mekhoa e mecha.

Joale Sintered Metal Filter ke eng?

Tlhaloso e bonolo ea sintered metal filter:

Ke filtara ea tšepe e sebelisang likaroloana tsa phofo tsa tšepe tse tšoanangboholo ba karoloanaho bōptjoa ka setempe,

boemo ba mocheso o phahameng oa mocheso. Sintering ke mokhoa oa hometallurgy ka ho sebedisa bokae ba phofomele ea

litšepe le metsoako e fapaneng ka mor'a ho hatakela.

Metallurgy e etsahala ka ho hasana mochesong o ka tlase ho sebaka se qhibilihang sa libopi tsa mocheso o phahameng.

Litšepe le li-alloyse sebelisoang hangata kajenokenyeletsa aluminium, koporo, nickel, boronse, tšepe e sa hloekang,

le titanium.

Ho na le mekhoa e fapaneng eo u ka e sebelisang ho etsa phofo. Li kenyelletsa ho sila, atomization,

le ho bola ha lik'hemik'hale.

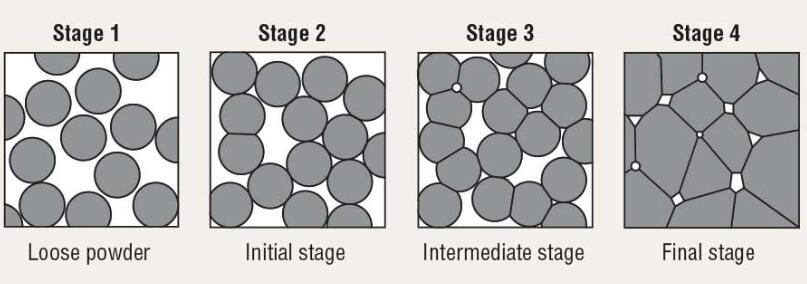

Seo Sintering Metal Filter Manufacturing Process

Joale, mona, re rata ho lekola lintlha tsa ts'ebetso ea tlhahiso ea Metal filter. haeba u thahasella, ka kopo sheba ka tlase:

1.) Sintering ke Eng, Hobaneng U Sebelisa Sintering?

Tlhaloso e bonolo ea sintering ke phofo ea tšepe e kopantsoeng hammoho ke mocheso o phahameng le mekhoa e meng ho

mojule o batloang.Lethathamong la micron, ha ho na moeli pakeng tsa likaroloana tsa phofo ea tšepe,

ke kahoo re ka laolang sebaka sa pore

ka mokhoa oa tlhahiso.

Cartridge ea porous ea mokhoa oa sintering e fana ka sebopeho se tsitsitseng sa tšepe 'me se fana ka

lintho tse bonahalang tse nang letshebetso ya ho tlhotla ka matla.

2.)3-Ka sehloohongMehato ea Sintered Metal Filter Manufacturing

A: Mohato oa Pele ke Ho Fumana Matla a Metal.

The tšepe phofo, O ka fumana tšepe powders ka sila, atomization, kapa ho bola ha lik'hemik'hale.

U ka kopanya tšepe e le 'ngoephofo ka tšepe e 'ngoe ho etsa motsoako nakong ea ts'ebetso ea masela,

kapa o ka sebelisa phofo e le 'ngoe feela. Molemo oa ho sintering ke horeha e fetole mmele

thepa ea thepa ea tšepe. Mokhoa ona o bonolo hoo likarolo tsa tšepe li sa fetoheng.

B: Ho hatakela

Mohato oa bobeli ke ho tšela phofo ea tšepe ka har'a hlobo e lokiselitsoeng pele eo u ka e bōpang filthara.

Kopano ea filthara e thehoa ka kamorengmocheso le tlasa setempe. Boima ba khatello e sebelisitsoeng

ho itšetlehile ka tšepe eo u e sebelisang, kaha litšepe tse fapaneng li na le elasticity e fapaneng.

Ka mor'a tšusumetso e phahameng ea khatello, phofo ea tšepe e kopanngoa ka har'a hlobo ho etsa sefe se tiileng.Ka mor'a moo

ts'ebetso e phahameng ea khatello ea maikutlo, u ka khonabeha sefe e lokisitsoeng ea tšepe ka sebōping sa mocheso o phahameng.

C: Sintering ea mocheso o phahameng

Ts'ebetsong ea sintering, likaroloana tsa tšepe li kopantsoe ho etsa yuniti e le 'ngoe ntle le ho fihla sebakeng sa ho qhibiliha.

Monolith ena e matla joalo kae thata, ebile e porous sefene joalo ka tšepe.

O ka laola porosity ea filthara ka ts'ebetso ho latela boemo ba phallo ea moea kapa mokelikeli o lokelang ho tlhotloa.

Lebitso la boemo ba media ba sintered le lekana le pore e bolelang phallo, kapa boholo bo boholo ba sefe.

Sintered tšepe mecha ea litaba bae fanoa ka limaraka tsa 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 le 100. The filtration rating in

mokelikeli bakeng sa limaraka tsa mecha ea litaba 0.2 ho isa ho 20 o pakeng tsa 1.4 le 35 µmfeletseng. Sekhahla sa ho sefa mekhahlelong ea khase

ho tloha ho 0.1 ho isa ho 100 µm ka botlalo.

Hobaneng o ka Sebelisa Metal Sintering ho Etsa Sefe?

Ena ke potso e ntle, ke hobane'ng ha u sebelisa tšepe ho etsa sefe?

Karabo e bonolo, ’me le hoja ho na le mabaka a mangata, litšenyehelo ke tsa bohlokoa ka ho fetisisa.

Ke Hobane'ng ha Litšenyehelo?

Ee, tshipi e e tshetsweng e na le kago e e tsepameng mme e ka dirisiwa gape, ya phepafatsa le go dirisiwa gantsi.

Hape, litšepe tse fapaneng li na le thepa e tsitsitseng ea 'mele le ea lik'hemik'hale' me ha e senyehe habonolo.

Ke ka lebaka leo li-Filters tse ngata tsa Sintered li sebelisoang liindastering tse fapaneng.

Likhetho tsa Lintho ke lifeLisefa tsa Sintered?

Ka tsoelo-pele e tsoelang pele ea theknoloji ea phofo ea metallurgy, ho na le likhetho tse ngata tsa

lisebelisoa tsa li-filters tsa tšepe tse sintered,

U ka khetha ho tsoa litšepe tse ling tse ngata le lialloys ho fihlela litlhoko tse ikhethang tsa maemo a holimo

mocheso le khatello, kutuho hanyetsa joalo-joalo, Lisebelisoa tse ka sehloohong tsa tšepe tse kang:

-

Sefe ea tšepe e se nang tšepe; 316L, 304L, 310, 347 le 430

-

Boronse

-

Inconel® 600, 625 le 690

-

Nickel200 le Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Alloys

Sinteredli-filters tsa tšepe tse sa hloekang, ho kenyeletsoa li-cartridge tsa filthara, lipoleiti le li-tubes tse entsoeng ka tšepe e sa hloekang

304 le 316, li fana ka katleho e phahameng ea ho sefa, bophelo bo bolelele ba ts'ebeletso, le ho feto-fetoha ha maemo lits'ebetsong tsa metsi ka bobeli.

le ho sefa khase. Li sebetsa hantle libakeng tse futhumetseng le tse senyang.

Ho tla sebelisoa tšepe e eketsehileng nakong e tlang.

8-Melemo e ka Sehloohong ea Sintered Metal Filter

1. ) Ho hanyetsa kutu

Litšepe tse ngata ka tlhaho li hanana le kutu, joalo ka sulfide, hydrides, oxidation, joalo-joalo.

2. ) Ho tlosoa ka katleho hoa litšila

Ho fetola porosity ea cartridge ho mokelikeli ho bolela hore u ka finyella se phethahetseng

filtration u batla le fumana alero le senang ditshila. Hape, kaha filthara ha e senyehe,

karabelo ea sefe ha e hlahise botengya ditshila tse lerong.

3. ) Tšisinyeho e Phahameng ea Thermal

Nakong ea ts'ebetso ea tlhahiso, mocheso o phahameng o hlahisoa, le thepa ea 'mele ea

litšepe tsena thusa ho monyatšisinyeho e kholo ea mocheso oa sefe. Ka lebaka leo, u ka sebelisa tsena

disefe ka mefuta e fapaneng ya ditshebediso ho itšetlehile kamocheso oa mocheso oa kopo.

Ho tsosoa ho hoholo ha mocheso ho boetse ho tiisa hore ho na le mokelikeli o sebetsang hantle ntle le ho tšoenyeha ka

mocheso oa kopo.

4,) Ho theoha ha Khatello e utloahalang

Asintered metal filtere ka boloka khatello ea mokelikeli ts'ebetsong ea hau, kahoo e netefatsa

boholo ba tshebetso.

Ho theoha hanyane ho ka senya ts'ebeliso ea hau.

5. ) Mocheso le Khatello Resistance

U ka sebelisa filthara ena lits'ebetsong tse nang le mocheso o phahameng le likhatello ntle le

ho tšoenyeha ka karolo ea hau ea sefa.

Ho sebelisa li-filters tsa tšepe tse sintered ts'ebetsong ea tlhahiso ea lik'hemik'hale le khase

dimela kalafo etsa bonnete ba hore ofumana liphetho tse ntle ka ho fetisisa tsa ho sefa.

6. ) E thata ebile e hanana le ho robeha

Molemo o mong oa ho sebelisa filtara ea tšepe e sintered ke hore e matla ebile e hanyetsana le

robeha.

Nakong ea ts'ebetso ea tlhahiso, ho tlamahanngoa ha tšepe ho etsahala ka mocheso hantle

ka tlase ho ntlha e qhibidihang.

Sehlahisoa se hlahisoang ke filthara ea tšepe e thata e ka mamellang mefuta e fapaneng

dibaka tse thata.

Mohlala, o ka e sebelisa lits'ebetsong tse hlokang likhohlano ntle le tšabo ea ho robeha.

7.) Mamello e Ntle

Mamello e ntle e bolela hore filthara ea hau ea sintered ea tšepe e ka sefa mokelikeli oa hau ntle le ho arabela.

Hang ha ho sefa ha hao ho felile, sefa sa tšepe se sirelelitsoeng se tla boloka litšobotsi tsa sona tsa 'mele.

Leha ho le joalo, ho ka thusa haeba u etsa bonnete ba hore tšepe eo u e khethang bakeng sa filthara ea hau e ke ke ea

itšoara ka mokelikeli oo o o sefang

8.) Mefuta e mengata ea Menyetla ea Geometri

Li-cartridges tse sintered li u lumella ho thabela mefuta e mengata ea likhetho tsa geometri. U ka finyella

sena ha o ntse o kenya phofoho kenya dae nakong ya tlhahiso.

Hlobo ke eona e lokelang ho rala sefe ea hau.

Ka hona, u na le bolokolohi ba ho sebelisa moralo ho latela litlhaloso tsa hau.

Mohlala, haeba ts'ebeliso ea hau e hloka sefe e nyane, o ka fetola moralo habonolo

ho fumana e nyane

sintered metal filter.Ka mokhoa o ts'oanang, haeba sesebelisoa sa hau se na le moralo o ikhethileng, u ka khona habonolo

tsamaisa moralo kahlobo nakong ea tlhahiso.

Li-filters tsa Sintered Metal li sebetsa joang?

Bothata bona bo ka boela ba boleloa hore ke molao-motheo oa ho sebetsa oa li-filters tsa tšepe tse sintered. Batho ba bangata ba nahana

hore potso ena keho thata haholo ho araba, 'me ha ho joalo.U ka 'na ua makatsoa ke sena, empa mohlomong uena

e ke ke ea ba ka mor'a ho bala tlhaloso ea ka.

Li-filters tsa tšepe tse sirelelitsoeng li bohlokoa haholo. Pokello ea litšila e hlaha ka holim'a

mokelikeli; ha emokelikeli o feta filtara ea tšepe, thelikaroloana tse kholo le litšila li tla ba

setseng ka lehlakoreng le leng la khatriji, empa haho khetha boemo bo sebetsang ba ho sefa bakeng sa mokelikeli oa hau, uena

hloka ho etsa bonnete ba horee ka ba ea sefa litlhoko.

* Litlhoko tsena li kenyeletsa

1. Tšilafalo ea ho boloka Backwash bokhoni

2. Ho theoha ha Khatello

Bakeng sa ho theoha ha khatello, ho hlokahala hore u nahane ka lintlha tse 'maloa.

Lintlha tsena li kenyelletsa

AViscosity ea mokelikeli, lebelo la mokelikeli ha o ntse o phalla ka har'a karolo ea sefe, le litšobotsi tse silafatsang.

BLitšobotsi tse silafatsang li kenyelletsa sebopeho sa likaroloana, ho teteana, le boholo.

Haeba litšila li le thata ebile li le sebopeho se tloaelehileng, ho etsa kaka e teteaneng, joale ho hloekisa holimo ho loketse.

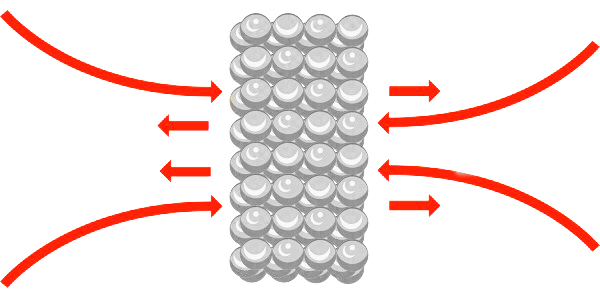

*Katleho ea Sintered Metal Filtration e Itšetlehile ka

1.khatello e eketsehileng e theoha ho fihlela moo khatello e feletseng e fihletsoeng teng.

2. ho phalla ho sa feleng hoa lero.

U ka finyella maemo a ho qetela ka ho tiisa litšila tse ntseng li eketseha ho fihlela moo khatello ea metsi e theohang teng.

Khatello ena e theoha ka mokhoa o sa khaotseng ho fihlela ho fokotseha ho hoholo bakeng sa viscosity e fanoeng le tlhokahalo ea tekanyo ea phallo e fihletsoe.

Taba e 'ngoe ea bohlokoa ke ho hlatsuoa ka morao ha filthara, e etsoang ka ho hatella khase skrineng le ka potlako.

ho bula valve ea ho ntša mokokotlojoalo ka ha mokokotlo o etsahala.

Phapang e phahameng ea reverse instantaneous pressure kehlahisoa. E tlosa ka katleho litšila tse tsoang ho sefa

bokaholimo ba ntho. Ka moraoho phalla ha mokelikeli o hloekileng ka ntho e hloekisang ho tlosa litšila le ho li tsamaisa

kantle ho sefe.

Ho phahama ho tsitsitseng ha sekhahla sa khatello ea khatello ho bontša kabo e tsitsitseng le e ts'oanang ea boholo ba litšila.To

finyella tse tsitsangtshebetso, o tlameha ho etsa bonnete ba hore ho theoha ha khatello ea element element ea filthara ho tsitsitse.Haeba mocheso

ea liphetoho mokelikeli, e amabokhabane ba lero. Tabeng ena, khatello e theoha ho pholletsa le sefeelement tla

eketsa 'me u se ke ua finyella phello ea filtration.

Ka hona, o hloka ho boloka mocheso o sebetsang oa filthara nakong ea ts'ebetso ea filthara le

etsa bonnete bamocheso oa lero le khatello.Ha u hloekisa filthara, u lokela ho latela

mokhoa o nepahetseng oa ho hlatsoa mokokotlo.

Lisebelisoa tsa Sintered Metal li sebetsa joang?

U ka utloisisa habonolo ha u hlahloba se latelangSetšoantšo sa molao-motheo oa ho sebetsa

Joalo ka ho latela ke sehlooho8-Mefutaea Themolao-motheo o sebetsang oa ho hloekisa tšepe, ke tšepa hore e tla u thusa

utloisisa haholoanyanebakeng sa joangSintered metal Filter e ka thusabakeng sa mokelikeli oa ho sefa, khase le lentsoe.

1.) Mokelikeli & Khase Filtration / Karohano

Li-filters tsa Sintered Metal li ka fokotsa kapa tsa tlosa ka botlalo lintho tse tsoang mokelikeli oa khase kapa oa metsi.

Taba e itseng e kakenyelletsa empa ha e felle feela ho likaroloana tse emisitsoeng (sediment, tšepe, letsoai, joalo-joalo),

algae, libaktheria, li-fungus spores, le tse sa batlehenglitšila tsa lik'hemik'hale/baeloji. Metal filter pore boholo

e ka etsa ho tloha ho 0.2 µm - 250 µm.

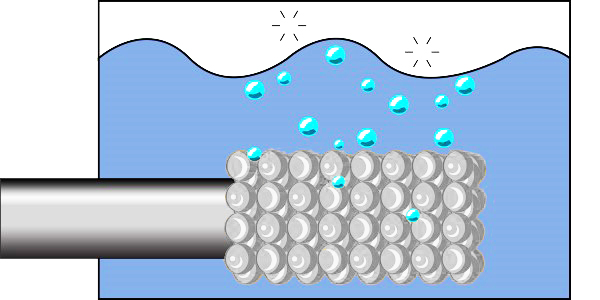

2.)Sparger

Tse ling tsa lisebelisoa tsa ho hloekisa:

Soda carbonization

Beer Carbonization

OksijeneHo tlosoa ha Oli e jeoang

Sparging ke ho kenya khase ka har'a mokelikeli. E sebelisetsoa ho tlosa khase e qhibilihileng e sa batleheng

(ho ntša oksijene) kapaseedi se qhibilihileng. E ka boela ea sebelisa ho hlahisa khase ka har'a mokelikeli (carbonization).

Ho phatloha ho tloaelehileng ho ile ha etsa lipululanaka bophara ba 6 mm. PM filter sparging e lumella hore ho be le tse nyane le ho feta

bubble bophara, kahoo ho eketsa sebaka se ka holimo salipululana li etsa hore ho be le pholiso e sebetsang hantle

kopo ka ho fokotsa nako ea ts'ebetso.

3.) Breather Vents

Li-filters tsa tšepe tse sintered li boetse li sebelisoa e lemaqhutsu a phefumolohangka li-cylinders, li-gearbox, manifolds, li-hydraulic system,

matamo, le litsamaiso tse ling. Maqhubu a phefumolohang a lumella ho lekanngoa ha khatello le moea / khase ho kena le ho tsoa tsamaisong

ha e ntse e thibela ntho e itseng ho kena tsamaisong. Li-discs tsa sintered bronze filter li sebetsa ka ho khetheha

ka li-motor tsa motlakase, ho thibela ho kena ha lerōle, mongobo le litšila tse ling ha li ntse li lumella moea.

phapanyetsano, e leng ea bohlokoa bakeng sa ho boloka tikoloho ea ka hare ea motlakase le ho netefatsa hore e nepahetse

tshebetso le bophelo bo bolelele. Li-filters tsa tšepe li ka khutlisetsoa ho hlatsuoa ho tlosa lintho tse nyenyane, ho li fa nako e telele

nako ea bophelo joalo ka moea o phefumolohang hofeta mecha e meng ea sefe.

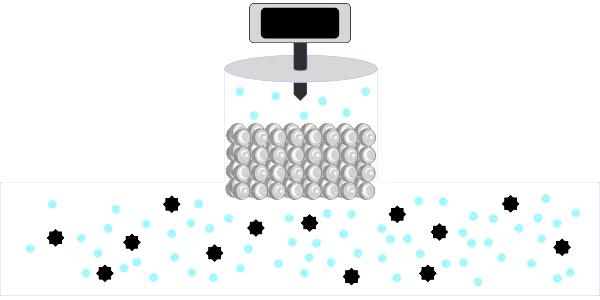

4.) Tšireletso ea kutlo

Sintered Metal Filters le eona e ka sireletsa likarolo tsa elektroniki joalo ka sekoaelo, joalo ka li-thermometers,

li-sensor tse fapaneng,senotlololikarolo tsa litsamaiso tsa bongaka, le lihlahisoa tse ling tse hlokolosi tse tsoang metsing,

maro, lerole, lephetoho ea khatello.

5.) Taolo ea Phallo ( Throttling / Dampening )

E khethehilengsintered filtere ka laola ho phalla ka har'a moea, khase, vacuum, le tsamaiso ea phallo ea mokelikeli. The

seaparo sa sefeboholo ba porelumella hore ho be le taolo e tsitsitseng, e pheta-phetoang ea phallo le ho sireletsa li-valve, li-sensor,

le eng kapa eng e ka tlase ho nokatsamaisong ho tlohalitšila. Taolo ea phallo e sebelisoa ho joalo

lisebelisoa e le li-timers tsa pneumatic, taolo ea phepelo ea khaselikarolo, le ho lieha ha nakoelements ka

lisebelisoa tsa likoloi.

6.) Li-Silencers tsa Moea o Exhaust

Li-filters tse sintered le tsona li ka tšeloa kapa tsa hokelloa ka sinter ho eng kapa eng e hlokahalang, e li lumellang hore li sebetse e le sesebelisoa.

exhaust silencer.Sesefa ha se khone ho sireletsa feela li-solenoids le manifolds ho tsoa ho litšila tse ka hare ho

tsamaiso empa hape e fokotsa lerataboemo ba ho felloa ke matla ho tsoa ho sistimi. Thesethusa-moya se ntshang moyasefehla

hapefokotsa moea o fokang ho tsoa tsamaisong, e lengfokotsa litšila, Ho sireletsa

tikoloho.

7.) Phallo / Khatello Equalization

Li-filters tse sintered li ka lekanya le ho laola sekhahla sa phallo le khatello ea sistimi. Ho lekana ho sireletsa

litsamaiso khahlano le ho phahamala mokelikeli le ho etsa phallo e ts'oanang ha khase kapa lero le ntse le tsamaea

li-pores tse tšoanang.

Li-filters tsa Sintered li sebelisetsoa eng?

Bakeng sa potso ena, Ha e le hantle batho ba bangata ba tla botsa Ke ts'ebeliso efe ea Sintered metal Filters?

Ka mor'a ts'ebetso e rarahaneng joalo, ba tla sintered hokaeli-cartridge tsa filthara ea tšepeho sebelisoa?

'Nete ke hore u ka fumana li-filters tsena liindastering tse fapaneng.

Lisebelisoa tse tloaelehileng li kenyelletsa tse latelang.

1) Ho sebetsana le lik'hemik'hale

U ka fumana li-filters tsa tšepe tse sirelelitsoeng indastering ea solvent ea lik'hemik'hale le ea khase, ho kenyeletsoa le

indasteri ea nyutlelie.Ho bola, mocheso o phahameng, le ho se sebetsane le lik'hemik'hale ho etsa tšepe e kentsoeng

sefa molemo o ikhethang ho

indasteri ea ho lokisa lik'hemik'hale.

2) Ho hloekisa peterole

Bakeng sa tlhoekiso ea peterole, ho sefa mafura a fapaneng ka nepo

Re hloka ho sebelisa li-filters tse fapaneng tsa tšepe ho latela boemo ba degree ho phethela tlhoekiso ea

mafura a khethehileng a tsoangsetoko sa lijo.E, li-filters tsa tšepe tse sintered li ka u thusa ho fihlela sepheo sena.

Hobane li-filters tsa tšepe ha li sebetse ka lik'hemik'hale ka mafura.

Ka hona, mafura a khethehileng a ke ke a ba le litšila leha e le life ka mor'a ho sefa.

Ho phaella moo, u ka e sebelisa ka mocheso ho fihlela ho 700 °, e leng ntho e tloaelehileng ho hloekisa petroleum.

3.) Ho hlahisa matla

Ho hlahisa matla a motlakase ka metsi ho hloka ts'ebetso e tsoelang pele ea turbine. Leha ho le joalo, the

tikoloho kae leng turbinee sebetsa hangata e hloka ho sefa ho fumana metsi a mangata

eo turbine e hlokang ditshila.

Haeba turbine e tletse litšila, e tla nyoloha ebe e thibela turbine ho potoloha,

ebe turbine e tlaha e fehle motlakase. U ka sebelisa li-filters tsa tšepe tse sintered ho netefatsa

tlhahiso ea matla e sebetsang hantle le e sebetsang hantle.

Lisefe tsena li sebelisetsoa ho fehla motlakase ka ho sefa metsi ho tsoa mochining oa motlakase.

Hobane ha li senyehe ke metsi, turbine e tla sebetsa nako e telele.

4.) Ho hlahisa khase ea tlhaho

Sebaka se seng sa bohlokoa sa kopo bakeng sa li-filters tsa tšepe tse sintered ke tlhahiso ea khase.

Li-filters tsa tšepe tse sirelelitsoeng li bohlokoa haholo tlhahisong ea khase hobane ha li sebetsane le khase,

'me u ka li sebelisalibakeng tse fapaneng.

5.) Lijo le seno

Lisebelisoa tsa tšepe li ntša limatlafatsi le lero la bohlokoa indastering ea ho lokisa lijo le lino.

Lisebelisoa tsa tšepe li sefa hantle le ho thibela limatlafatsi tsena hore li se ke tsa hohola nakong ea ts'ebetso.

Molemo oa li-filters tse tšoanang tsa tšepe ke hore ha li sebetse ka lijo kapa lino tse itseng.

Ha o sebelisa li-filters tsena o netefatsa boleng ba ts'ebetso ea hau ea tlhahiso.

9. Ke ea mofuta ofeSintered Metal FiltersHENGKO Can Supply ?

HENGKO phepelo ea mantlha 316L, 316 le lifaele tsa tšepe tse sirelelitsoeng tsa boronse. sebopeho se seholo joalo ka lenane le latelang:

1.Sefe ea tšepe e se nang tšepeDiski,

2.StainlessSefe ea tšepeTube,

3.Stainless Sefe ea tšepeLetlapa,

4.Sefe ea tšepe e se nang tšepeLikopi,

joalo-joalo, sebopeho sefe kapa sefe seo morero oa hau o se hlokang.

Ehlile, rea fanaTšebeletso ea OEM

1.OEMSebopeho:Diski, Mohope,Tube, Plate ect

2.IketsetseBoholo, Bophahamo, Bophara, OD, ID

3.Boholo ba Pore bo ikhethileng /Metsuho tloha ho 0.1μm - 120μm

4.Iketsetse Botenya bo fapaneng

5. Mono-layer, Multi-layer, Mixed Materials

6.Moralo o kopaneng o nang le matlo a 304 a tšepe e sa hloekang

Bakeng sa lintlha tse ling tsa OEM, ka kopo ikopanye le HENGKO Kajeno!

Ke ntse ke na le Lipotso Joang ho Tseba Lintlha Tse ling Bakeng sa Sensor ea Tlhokomelo ea Mongobo,

Ka kopo, ikutloe u lokolohile ho Iteanya le Rona Hona joale.

Hape U ka khonaRe romelle ImeileKa ho toba ka tsela e latelang:ka@hengko.com

Re tla khutlisa ka lihora tse 24, re leboha mokuli oa hau!

Re romelle molaetsa oa hau:

Nako ea poso: Aug-20-2022