Sintering e bapala karolo ea bohlokoa indastering ea tlhahiso, e nolofalletsang tlhahiso ea likarolo tse rarahaneng le tse tšoarellang. Ho utloisisa metheo ea ho bina ho bohlokoa ho lienjineri, bafuputsi le ba chesehang ka ho tšoanang. Sengoliloeng sena se ikemiselitse ho tebisa mohopolo oa sintering, ho lekola ts'ebetso ea ona, ho buisana ka ts'ebeliso ea ona, le ho totobatsa melemo le meeli ea ona.

Sintering ke eng?

Sintering ke ts'ebetso e kenyelletsang ho kopanya thepa e phofshoana hore e be boima bo tiileng ka ho sebelisa mocheso. Ho fapana le mekhoa e tloaelehileng ea ho qhibiliha, sintering ha e fihle boemong ba ho qhibiliha ha thepa. Ho e-na le hoo, e sebelisa ho hasana ha liathomo ho pholletsa le likaroloana, e leng se lebisang ho tlamahaneng le ho teteaneng. Ts'ebetso ena e fella ka mohaho o tiileng o nang le thepa e ntlafetseng ea mechine.

Sintering e boetse e na le kutloisiso e pharaletseng le e moqotetsane. Bakeng sa kutloisiso e pharaletseng, sintering ke mokhoa oo phofo e hlephileng e kopantsoeng ho ba li-blocks ka matla a tiileng a ho kopanya mocheso o itseng. Empa sintering tšimong ea ho etsa tšepe ke mokhoa o kopanyang phofo ea tšepe ea tšepe le lisebelisoa tse ling tse nang le tšepe ka har'a ts'ebetso e ntle ea metallurgic block block ea maiketsetso ka fusion, tlhahiso ea eona ke sinter. Li kenyelletsa lits'ebetso tse fapaneng tsa physicochemical Le hoja ka bobeli ba sebelisitse lentsoe sintering.

Mokhoa oa Sintering

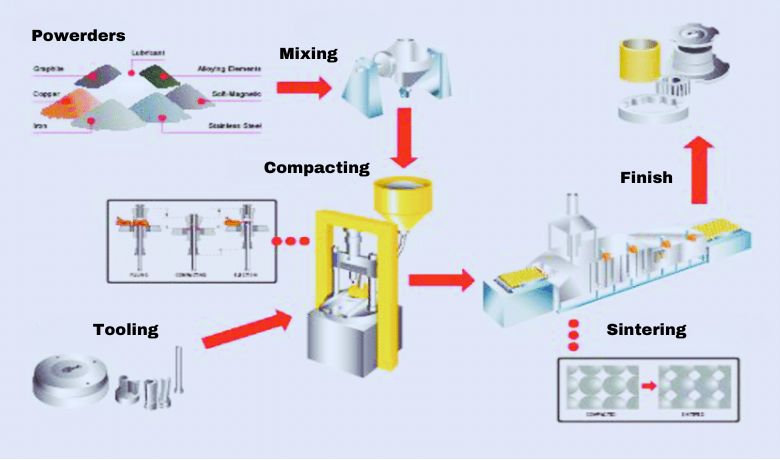

Mokhoa oa sintering o na le mekhahlelo e mengata. Qalong, thepa e tala e thehoa ka sebōpeho se itseng, hangata e le phofo. Joale phofshoana ena e hatelloa ka ho sebelisa khatello ho tiisa ho tšoana le ho felisa li-voids. Ka mor'a moo, thepa e kopantsoeng e kenngoa mocheso o laoloang ka sebōping sa sintering. Mocheso o laoloa ka hloko ho thusa ho kopanya likaroloana ntle le ho baka ho qhibiliha ho feletseng. Nakong ea ho futhumatsa, likaroloana li kena ka har'a ho ata, e leng se lebisang ho thehoa ha molala le ho tiisa. Mokhahlelo oa ho qetela o kenyelletsa ho pholisa sehlahisoa sa sintered, ho se lumella hore se tiee ho ba sebopeho se thata le se momahaneng.

Phofo eo re neng re re ke phofo ea tšepe kapa phofo e kopaneng. Ke ts'ebetso ea matsoho ea ho fumana thepa kapa sehlahisoa ka matla le litšobotsi tse hlokahalang ka lebaka la tlamahano ea 'mele le ea lik'hemik'hale pakeng tsa likaroloana ka mocheso o ka tlase ho ntlha ea ho qhibiliha ea karolo e ka sehloohong. HENGKO e na le letoto la lihlahisoa tsa sintering tsa phofo tsa mefuta e fapaneng ea litlhaloso le boholo bo kenyelletsangsefahla sa disc, filthara ea senoelo,sefahla sa kerese,sefefo sa letlapajoalo joalo. Sehlahisoa sa rona sa tšepe sa sintering se na le monyetla oa ho ba le matla a phahameng, ho kenella hantle, ho nepahala ho nepahetseng ho sefa le ho hanyetsa kutu, ho loketse libaka tse ngata. Litšebeletso tse ikhethileng le tsona li fanoe kamoo u kopileng kateng.

Mohato o mong le o mong oa ts'ebetso ea sintering ke oa ho sebelisana, 'me ho tsepamisa mohopolo ke mohato oa bohlokoa haholo ts'ebetsong ea sintering, joale concentrate e bolela'ng?Concentrate ke mohato o nkang khato ho ntlafatsa thepa e tala le mafura, e leng se etsang hore e be moroalo oa sebōpi o kopanang le litlhoko tsa ho matlafatsa ho hloekisoa ha sebōpi pele ho lintho tse tala le mafura li kena ka sebōping sa mollo. Lipontšo tse phahameng tsa tekheniki le moruo le melemo ea moruo li ka fumanoa ka mor'a hore concentrateis e sebelisoe ho phatloha ho qhibilihisa ha sebōpi. Seo ho thoeng ke "sebelisa ntho e 'ngoe le e' ngoe hantle" 'me u sebelise matlotlo hamolemo. Hape ke mofuta oa tlhokomeliso ea ho boloka le ho sireletsa tikoloho.

Lintlha tse Amang Sintering

Lintlha tse 'maloa li susumetsa ts'ebetso ea sintering, ho kenyelletsa mocheso, sekhahla sa ho futhumatsa, khatello, boholo ba likaroloana le sebopeho. Mocheso o bapala karolo ea bohlokoa ho khethollang sintering kinetics le sephetho sa thepa. Sekhahla sa ho futhumatsa se ama ts'ebetso ea densification, kaha ho futhumatsa ka potlako ho ka 'na ha lebisa ho se leka-lekaneng ha likaroloana. Khatello e sebelisoa nakong ea compaction ho ntlafatsa ho hlophisa bocha le ho felisa porosity. Boholo ba likaroloana le sebopeho li ama boitšoaro ba sintering, ka likaroloana tse nyane le liqapi tse ts'oanang tse khothalletsang ho kopanya hantle.

Ho ea ka pono ea sebele ea lentsoe sintering, lentsoe ho chesa ke ho sebelisa mollo, ho tlameha ho be le lelakabe le tsamaeang le mocheso o phahameng. 'Me mokhoa oa sintering o tlameha ho etsoa ka mocheso o phahameng. Mocheso o phahameng o etsoa ke ho chesoa ha mafura. Mocheso oa mocheso, lebelo le tukang, bophara ba sehlopha se tukang, sepakapaka linthong tse sintered, joalo-joalo li tla ama tsoelo-pele ea sintering le boleng ba lihlahisoa tsa ho qetela tsa sintered. 'Me likarolo tseo li amana le thepa ea' mele le ea lik'hemik'hale ea mafura le litekanyetso. Ka hona, thepa ea 'mele le ea lik'hemik'hale ea mafura ke ntho ea bohlokoa e amang mokhoa oa sintering.

Mokhabo-puo ntho e ke ke ea e-ba teng ntle le motheo oo ba phelang ho oona. Mafura le lisebelisoa tse tala li tšoana le letlalo, 'me patsi e nang le kamano ke ea bohlokoa haholo. Ntle le e 'ngoe, Ts'ebetso ea sintering e ke ke ea etsahala. Empa mafura a Sintered haholo-holo a bua ka mafura a tiileng a tukang lera la thepa. Tse sebelisoang ka ho fetisisa ke phofo ea coke e silafalitsoeng le anthracite, joalo-joalo. Lisebelisoa tse tala tse silafalitsoeng, haholo-holo li na le tšepe, tšepe ea manganese, solvent, mafura le litšila tsa indasteri.

Mefuta e sa tšoaneng ea Sintering

Sintering e akaretsa mekhoa e fapaneng e arotsoeng ho latela mekhoa le maemo a amehang ts'ebetsong. Ho utloisisa mefuta e fapaneng ea sintering ke habohlokoa bakeng sa ho khetha mokhoa o nepahetseng bakeng sa lisebelisoa tse khethehileng. Mona ke mefuta e meng e tloaelehileng ea sintering:

1 Solid-State Sintering

Solid-state sintering, eo hape e tsejoang e le diffusion bonding, ke mokhoa o sebelisoang haholo oa sintering. Ts'ebetsong ena, lisebelisoa tse phofshoana li beoa tlas'a mocheso o phahameng ka tlase ho moo li qhibilihang. Ha mocheso o ntse o eketseha, ho ata ha athomo ho etsahala pakeng tsa likaroloana tse haufi, ho nolofalletsa ho thehoa ha melala le ho tlamahanngoa. Ho felisoa ha li-voids le ho hlophisoa bocha ha likaroloana ho lebisa ho densification le ho thehoa ha boima bo tiileng.

Solid-state sintering hangata e sebelisoa ha ho etsoa lirafshoa, tse kang porcelain le alumina, hammoho le ho chesoa ha phofo ea tšepe. E ratoa ha ho boloka sebopeho sa lik'hemik'hale le bohloeki ba thepa ke habohlokoa. Ka ho laola ka hloko li-parameter tsa sintering, tse kang mocheso, nako, le khatello, thepa ea thepa e lakatsehang e ka finyelloa.

2 Liquid-Phase Sintering

Liquid-phase sintering e kenyelletsa ho eketsoa ha karolo ea mokelikeli ho thusa ho hlophisa bocha le ho kopanya nakong ea ts'ebetso ea sintering. Karolo ea mokelikeli, hangata e le thepa e tlaase ea ho qhibiliha, e sebetsa e le sekontiri kapa se phallang, se fokotsa mocheso oa sintering o hlokahalang bakeng sa ho kopanya. Mokhoa ona o na le thuso haholo ha lisebelisoa tsa sintering tse nang le lintlha tse phahameng tsa ho qhibiliha kapa ha ho hlokahala sekhahla sa densification.

Nakong ea sintering ea mokelikeli, mokelikeli oa mokelikeli o ata pakeng tsa likaroloana, o khothalletsa ho hlophisoa ha likaroloana le ho ntlafatsa sebopeho sa molala le ho tiisa. Ho ba teng ha karolo ea mokelikeli ho boetse ho nolofalletsa ho tlosoa ha litšila le ho thusa ho sintering ha lisebelisoa tse nang le lihlopha tse rarahaneng.

Liquid-phase sintering e atisa ho sebelisoa ha ho etsoa li-carbides tse entsoeng ka samente, moo likaroloana tsa tungsten carbide li kopantsoeng ho sebelisa sekontiri se entsoeng ka cobalt. E boetse e sebelisoa ha ho chesoa lirafshoa tse itseng le lialloi tsa tšepe, joalo ka tšepe e sa hloekang.

3 Activated Sintering

Activated sintering, eo hape e tsejoang e le sintering-assisted sintering kapa spark plasma sintering, ke mokhoa o mocha oa sintering o sebelisang mehloli ea matla a kantle ho khothaletsa tšubuhlellano. E kenyelletsa ts'ebeliso ea lebala la motlakase, maqhubu a motlakase kapa mahlaseli a motlakase ho ntlafatsa ts'ebetso ea sintering.

Mohloli oa matla o ka ntle o potlakisa ho ata ha athomo, e lebisang ho popeho e potlakileng ea molala le ho teteana. Tšebeliso ea matla a motlakase e etsa hore ho futhumale sebakeng sa heno, ho fokotsa nako ea sintering le ho etsa hore lisebelisoa li be le mocheso o tlase. Mokhoa ona o fana ka melemo e kang ho ntlafatsa ho tiisa, ho fokotsa kholo ea lijo-thollo, le taolo e ntlafetseng holim'a microstructure le thepa.

Sintering e kentsoeng e fumana lits'ebetso likarolong tse fapaneng, ho kenyeletsoa tlhahiso ea lirafshoa tse tsoetseng pele, lisebelisoa tse sebetsang le likhomphutha. E na le molemo ka ho khetheha bakeng sa lisebelisoa tse nang le lintlha tse phahameng tse qhibilihang, liqapi tse rarahaneng, kapa li-sinterability tse fokolang.

4 Mefuta e meng ea Sintering

Ntle le mefuta e boletsoeng ka holimo, ho na le mekhoa e meng e mengata e khethehileng ea sintering e etselitsoeng lisebelisoa tse khethehileng. Tsena li kenyelletsa microwave sintering, moo matla a microwave a sebelisetsoang ho futhumatsa le ho chesa thepa, le sintering e thusang khatello, e kopanyang khatello le mocheso ho matlafatsa ho teteana.

Ntle le moo, selective laser sintering (SLS) le electron beam sintering (EBS) ke mekhoa ea tlatsetso ea tlhahiso e sebelisang maballo a matla ho khetha lisebelisoa tse phofshoana, lera ka lera, ho hlahisa lintho tse rarahaneng tsa mahlakore a mararo.

Mofuta o mong le o mong oa sintering o fana ka melemo e ikhethang mme o khethoa ho ipapisitsoe le thepa ea thepa, liphetho tse lakatsehang, le lits'ebetso tse ikhethileng.

Lisebelisoa tsa Sintering

Sintering e fumana lits'ebetso tse pharalletseng liindastering tse fapaneng ka lebaka la bokhoni ba eona ba ho fetola thepa e phofshoana hore e be likarolo tse tiileng tse nang le thepa e ntlafalitsoeng. Ha re hlahlobeng tse ling tsa libaka tsa bohlokoa moo sintering e sebelisoang haholo:

1 - Ceramics

Ceramics ke e 'ngoe ea masimo a mantlha moo sintering e sebelisoang haholo. Li-ceramics tsa sintered li bonts'a matla a mochini, ho thatafala le botsitso ba mocheso. Sintering e sebelisoa ho hlahisa lithaele tsa ceramic, sanitaryware, lisebelisoa tsa ho itšeha, lisebelisoa tsa refractory le li-insulators tsa motlakase. Ka ho laola ka hloko li-parameter tsa sintering, lisebelisoa tsa ceramic li ka fihlela sekhahla se lakatsehang, porosity le microstructure bakeng sa lits'ebetso tse ikhethileng.

2 - Metallurgy

Lisebelisoa tsa metallurgical, sintering e sebelisoa ho etsa mefuta e mengata ea lisebelisoa tsa tšepe. Sena se kenyelletsa likere, li-bearings, bushings, likarolo tsa koloi le likarolo tsa sebopeho. Metal powders, joalo ka tšepe, aluminiamo le tšepe e sa hloekang, lia kopanngoa le ho silafatsoa ho hlahisa likarolo tse tiileng tse nang le lisebelisoa tse ntle haholo tsa mochini. Likarolo tsa tšepe tse sirelelitsoeng hangata li bonts'a matla a holimo, khanyetso ea ho roala, le ho nepahala ha boholo ha ho bapisoa le likarolo tsa setso.

3 - Likopano

Sintering e bapala karolo ea bohlokoa tlhahisong ea lisebelisoa tse kopaneng, moo lisebelisoa tse peli kapa ho feta tse fapaneng li kopantsoeng ho etsa lisebelisoa tse nang le thepa e ntlafalitsoeng. Ha ho etsoa metsoako ea tšepe ea matrix (MMCs) le metsoako ea ceramic matrix (CMCs), sintering e sebelisoa ho kopanya lisebelisoa tse matlafatsang, tse kang likhoele kapa likaroloana, le thepa ea matrix. Sena se matlafatsa matla, ho satalla le ho tiea ha motsoako o hlahisoang.

4 - Powder Metallurgy

Metallurgy ea phofo, lekala le ikhethileng la metallurgy, le itšetlehile haholo ka ho sintering. E kenyelletsa tlhahiso ea likarolo tsa tšepe ho tloha ho phofo ea tšepe. Ka mekhoa e kang ho kopanya le ho sintering, likarolo tse rarahaneng tse nang le libopeho tse rarahaneng li ka etsoa. Metallurgy ea phofo e atisa ho sebelisoa indastering ea likoloi bakeng sa tlhahiso ea likere, li-camshafts le litulo tsa valve, hammoho le ho etsa lisebelisoa tsa ho itšeha le li-filters tse sintered.

5 - 3D Printing / Additive Manufacturing

Sintering e bapala karolo ea bohlokoa mekhoeng ea ho etsa tlatsetso joalo ka selective laser sintering (SLS) le electron beam sintering (EBS). Lits'ebetsong tsena, lisebelisoa tse phofshoana li khethoa ka mokhoa o ikhethileng, ho latela meralo ea dijithale, ho theha lintho tse rarahaneng tsa mahlakore a mararo. Sintering e lumella ho kopanngoa le ho tlamahanngoa ha lintho tse entsoeng ka phofo, ho fella ka likarolo tse teteaneng ka ho feletseng le tse sebetsang. Theknoloji ena e sebelisoa liindastering tse fapaneng, ho kenyelletsa le sefofane, tlhokomelo ea bophelo bo botle le prototyping.

6 Boenjiniere ba Elektronike le Motlakase

Sintering e sebelisoa ho hlahisa likarolo tsa elektronike le tsa motlakase. Ha ho etsoa li-ceramics tsa elektroniki, joalo ka li-capacitor, varistors, le thermistors, sintering e sebelisetsoa ho kopanya likaroloana tsa ceramic, ho theha lisebelisoa tse teteaneng le tse tsamaisang motlakase. Sintering e boetse e sebelisoa ha ho etsoa likhokahano tsa motlakase, liphutheloana tsa semiconductor, le likarolo tsa boto ea potoloho.

Ena ke mehlala e seng mekae feela ea litšebeliso tse fapaneng tsa sintering. Ts'ebetso e ntse e tsoela pele ho hlahlojoa le ho ntlafatsoa ho fihlela litlhoko tse tsoelang pele tsa liindasteri tse fapaneng, tse nolofalletsang tlhahiso ea lisebelisoa le likarolo tse sebetsang hantle.

Melemo ea Sintering

Sintering e fana ka melemo e mengata e etsang hore e be mokhoa o ratoang oa ho etsa liindasteri tse fapaneng. Ha re hlahlobeng e meng ea melemo ea bohlokoa:

1 Libopeho tse Ratang le Meralo e Ratang

O mong oa melemo ea bohlokoa ea sintering ke bokhoni ba eona ba ho hlahisa likarolo tse nang le libopeho tse rarahaneng le meralo e rarahaneng. Ka ho sebelisa lisebelisuoa tse phofshoana, sintering e lumella ho thehoa ha likarolo tse nang le li-geometri tse rarahaneng tseo ho ka bang thata ho li finyella ho sebelisoa mekhoa ea setso ea ho etsa mechine. Ho feto-fetoha ha sebopeho sena ho nolofalletsa tlhahiso ea likarolo tse ikhethileng tse lumellanang le lits'ebetso tse itseng.

2 Thepa e Ntlafetseng ea Mechini

Sintering e ntlafatsa thepa ea mochine, e hlahisang likarolo tse nang le litšobotsi tse phahameng tsa ts'ebetso. Nakong ea ts'ebetso ea sintering, likaroloana li tlamahane le ho tiisa, tse lebisang ho matla a ntlafetseng, ho thatafala, le ho apara ho hanyetsa ha sehlahisoa sa sintered. Mekhoa e laoloang ea ho futhumatsa le ho hasana e amehang ho sintering e kenya letsoho ho nts'etsopele ea mohaho o teteaneng le o momahaneng, o matlafatsang botšepehi ba mochine oa motsoako.

Liqapi tse 3 tse Lokisitsoeng

Sintering e lumella ho kopanngoa ha li-powders tse nang le lihlopha tse fapaneng, tse nolofalletsang tlhahiso ea thepa e nang le thepa e entsoeng. Ka ho kopanya mefuta e sa tšoaneng ea phofo kapa ho kenyelletsa li-additives, hoa khoneha ho fetola litšobotsi tsa thepa ho latela litlhoko tse khethehileng. Ho feto-fetoha ha sebopeho sena ho bula menyetla ea ho theha lisebelisoa tse tsoetseng pele tse nang le ts'ebetso e ntlafalitsoeng, joalo ka li-alloys tse matla haholo kapa lisebelisoa tse nang le thepa e itseng ea motlakase kapa ea mocheso.

4 Litšenyehelo-Ka katleho

Sintering ke mokhoa o theko e boima oa tlhahiso ha o bapisoa le mekhoa e tloaelehileng ea ho qhibiliha le ho lahla. Tšebeliso ea lisebelisoa tse phofshoana e fokotsa litšila tsa thepa, kaha phofo e feteletseng e ka bokelloa le ho sebelisoa hape. Ho feta moo, ts'ebetso ea sintering e hloka tšebeliso e tlase ea matla kaha e sebetsa ka mocheso o ka tlase ho ntlha ea ho qhibiliha ea thepa. Bokhoni ba ho hlahisa likarolo tsa sebopeho se haufi le marang-rang bo fokotsa tlhokahalo ea ts'ebetso e latelang ea machining, e leng se bakang ho boloka litšenyehelo mabapi le tšebeliso ea thepa, tšebeliso ea matla le ts'ebetso ea morao-rao.

5 Ho Feta Lintho Tse Ngata ha ho Khetha Lintho

Sintering e fana ka mefuta-futa khethong ea thepa, e amohelang mefuta e mengata ea lisebelisoa bakeng sa lits'ebetso tse fapaneng. E loketse lirafshoa, tšepe le metsoako. Mefuta e fapaneng ea lisebelisoa, ho kenyeletsoa li-oxide, li-carbides, nitrides le li-alloys, li ka sebetsoa ka sintering. Tšebelisano ena e pharaletseng ea thepa e lumella ho hlahisa likarolo tse fapaneng tse nang le thepa e khethehileng ea thepa, ho etsa hore sintering e be khetho e khahlehang bakeng sa liindasteri tse ngata.

Melemo ea Sintering ka sebopeho se rarahaneng, thepa e ntlafalitsoeng ea mochini, liqapi tse hlophisitsoeng, ho baballa litšenyehelo, le ho feto-fetoha ha lintho tse ngata ho etsa hore e be mokhoa oa bohlokoa oa tlhahiso makaleng a fapaneng. Ka ho sebelisa melemo ena, liindasteri li ka fihlela tlhahiso e nepahetseng, ts'ebetso e ntlafalitsoeng, le ho boloka litšenyehelo lits'ebetsong tsa tsona tsa tlhahiso.

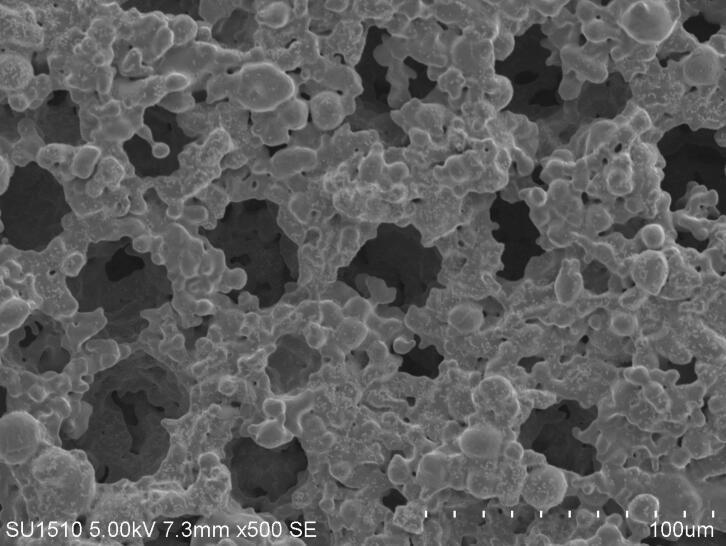

Ho na le liphetoho tse ngata tse kenyeletsang liphetoho tse rarahaneng tsa 'mele le lik'hemik'hale. Boitšoaro ba 'mele le lik'hemik'hale ho sintering ea phofo ho kenyelletsa mouoane kapa mouoane oa metsi kapa lintho tse phelang, ho tlosoa ha likhase tse adsorbed, ho imolla khatello ea maikutlo, phokotso ea li-oxide tse holim'a likaroloana tsa phofo, ho falla ha thepa, recrystallization, kholo ea lijo-thollo joalo-joalo Ho bohlokoa haholo ho ithuta. le ho utloisisa tsebo ea sintering joalo ka mohlahisi. 'Me joaloka bareki, ho ithuta tsebo ena ea motheo ho ka re thusa ho ba le maikutlo a matle ha re khetha lihlahisoa tsa sintering.

Sintering ke mokhoa oa setso le o rarahaneng. Linako li ntse li tsoela pele, 'me theknoloji ea tlhahiso le lisebelisoa tsa tlhahiso le tsona li lula li nchafatsoa. Ho boloka tsebo ea mantlha le ho ithuta tsebo e ncha hoa hlokahala bakeng sa basebetsi ba amanang le indasteri. Ka lilemo tse 18 tse fetileng.HENGKOkamehla e tsitlallela ho ntlafatsa kamehla, ho fana ka bareki ba lihlahisoa tse ntle le litšebeletso tse nahanelang, ho thusa bareki le nts'etsopele e tloaelehileng. Re tšepa ho ba molekane oa hau ea tšepahalang oa nako e telele.

Lipotso (Lipotso Tse Botsoang Hangata)

Ke lisebelisoa life tse ka siniloang?

Mefuta e mengata ea thepa e ka chesoa, ho kenyeletsoa lirafshoa, litšepe le li-composite. Mehlala e kenyelletsa li-powders tsa ceramic tse kang alumina le zirconia, li-powders tsa tšepe tse kang tšepe leli-filters tsa tšepe tse sa hloekang, le liphofshoana tse kopantsoeng tse nang le lisebelisoa tse matlafatsang joalo ka likhoele kapa likaroloana.

Melemo ea sintering ke efe ha e bapisoa le mekhoa e meng ea tlhahiso?

Sintering e fana ka melemo e mengata ho feta mekhoa ea setso ea tlhahiso. E lumella tlhahiso ea likarolo tse nang le libopeho tse rarahaneng le meralo e rarahaneng, e fana ka thepa e ntlafetseng ea mochine, e nolofalletsa ho etsoa ha lihlopha tsa thepa, e na le litšenyehelo tse ngata ka lebaka la litšila tse fokotsehileng, 'me e amohela mefuta e fapaneng ea lisebelisoa bakeng sa likopo tse fapaneng.

Lisebelisoa tsa mantlha tsa sintering ke life?

Sintering e fumana lits'ebetso liindastering tse kang ceramics, metallurgy, powder metallurgy, electronics, and additive production. E sebelisetsoa ho hlahisa lithaele tsa ceramic, likarolo tsa likoloi, likarolo tsa tšepe, lisebelisoa tsa ho itšeha, lirafshoa tsa elektroniki, le lintho tse hatisitsoeng tsa 3D, har'a tse ling.

Na ho na le mefokolo leha e le efe kapa mathata ka sintering?

Sintering e na le mefokolo le mathata. Ho fihlella densification e tšoanang ho pholletsa le thepa e ka ba phephetso, kaha ho futhumatsa ho sa tšoaneng kapa kabo ea likaroloana ho ka baka liphoso. Ho laola kholo ea lijo-thollo le ho thibela ho fokotseha ho feteletseng nakong ea sintering le tsona ke lintlha tsa bohlokoa. Ho feta moo, ha se lisebelisoa tsohle tse loketseng ho chesoa ka lebaka la maemo a phahameng a ho qhibiliha kapa ho ts'oaroa hape le sepakapaka se potolohileng.

Mefuta e fapaneng ea mekhoa ea sintering ke efe?

Ho na le mefuta e fapaneng ea mekhoa ea sintering, e kenyelletsang "solid-state sintering", "liquid-phase sintering", "activated sintering", "microwave sintering", "sintering" e thusang khatello, hammoho le mekhoa e ikhethileng e kang selective laser sintering (SLS) le electron beam sintering (EBS). Mokhoa o mong le o mong o na le mekhoa e ikhethang 'me o khethoa ho latela litlhoko tse khethehileng tsa thepa le ts'ebeliso.

Sintering e ntlafatsa thepa ea thepa joang?

Sintering e ntlafatsa thepa ea thepa ka ho khothalletsa ho kopanya likaroloana le ho kopanya. Nakong ea ts'ebetso ea sintering, likaroloana li kena ka har'a ho ata, tse lebisang ho thehoa ha molala le ho eketseha ha sekhahla. Sena se fella ka thepa e ntlafetseng ea mechine e kang matla, ho thatafala, le ho hanyetsa ho apara. Ho feta moo, sintering e ka lebisa ntlafatsong ea thepa ea motlakase, ea mocheso le ea lik'hemik'hale ho latela thepa le sebopeho sa eona.

Na likarolo tsa sintered li ka etsoa ka mochini kapa tsa sebetsoa hape?

Ee, likarolo tsa sintered li ka etsoa ts'ebetso e eketsehileng kapa machining, ha ho hlokahala. Le hoja sintering e ka finyella likarolo tse haufi-le-net-shape, ho ka 'na ha e-ba le liketsahalo tseo ho tsona ho hlokahalang ho sebetsa ka mokhoa o tsoelang pele ho finyella litlhoko tse lakatsehang. Mekhoa ea machining e kang ho sila, ho cheka kapa ho sila e ka sebelisoa ho finyella litekanyo tsa ho qetela kapa ho qeta holimo.

Ke lintlha life tsa tikoloho ea sintering?

Sintering ka kakaretso e nkuoa e le ts'ebetso ea tlhahiso e baballang tikoloho. E sebelisa matla a fokolang ha e bapisoa le mekhoa ea ho qhibiliha le ho lahlela, 'me e fokotsa litšila tsa lintho tse bonahalang ka ho lumella ho sebelisoa hape ha phofo e feteletseng. Leha ho le joalo, ho bohlokoa ho nahana ka phello ea tikoloho ea thepa e tala e sebelisitsoeng, hammoho le ho ts'oaroa le ho lahloa ka nepo ha lihlahisoa kapa litšila tse hlahisoang nakong ea ts'ebetso.

Sintering e kenya letsoho joang ntlafatsong ea lisebelisoa tse tsoetseng pele?

Sintering e bapala karolo ea bohlokoa ho nts'etsopele ea lisebelisoa tse tsoetseng pele. Ka ho khetha ka hloko le ho laola sebopeho, boholo ba likaroloana, le li-parameter tsa sintering, hoa khoneha ho lokisa thepa ea sephetho. Sena se lumella hore ho thehoe lisebelisoa tse tsoetseng pele tse nang le litšobotsi tse khethehileng, tse kang li-alloys tse sebetsang hantle, li-ceramics tse sebetsang, kapa lisebelisoa tse kopantsoeng tse nang le metsoako e ikhethang ea thepa.

Haeba u na le lipotso tse ling kapa u batla ho ikopanya le tsonaHENGKO,

ka kopo ikutloe u lokolohile ho ikopanya le rona ka imeile hoka@hengko.com.

Re ka thabela ho u thusa le ho fana ka lintlha life kapa life tse ling tseo u ka li hlokang.

Nako ea poso: Aug-14-2020