Diffusion Stone Le Carbonation Stone OEM Special Manufacturer

Majoe a Sintered Metal Special Diffusion Stones le Carbonation Stones a HENGKO a sebeletsa liindasteri tse ngata tse kenyelletsang meriana, phepelo ea lijo, likarolo tsa lino tsa khoebo le tsa malapeng, kalafo ea metsi a litšila le lik'hemik'hale tsa petrole, har'a tse ling. Litšebeletso tsa rona tsa OEM tse entsoeng ka mokhoa o ikhethileng li re lumella ho theha Diffusion le Carbonation Stones tse ikhethileng, tse etselitsoeng ho ntlafatsa ts'ebetso ea sistimi ea hau ea moea ho pholletsa le mekhoa e fapaneng e kang ho belisoa, oxidation le gasification.

Boinehelo ba rona ho boleng bo holimo, bots'epehi le boqapi bo re lebisa ho fana ka mefuta e fapaneng e fapaneng ea Sintered metal Diffusion le Carbonation Stones, e etselitsoeng ka hloko ho khotsofatsa litlhoko tsa hau. Haeba u na le litlhoko tse ikhethileng tsa projeke e tlang, kapa u lakatsa ho ntlafatsa sistimi e teng ea moea, sehlopha sa baenjiniere le litsebi tse nang le boiphihlelo ba HENGKO se ikemiselitse ho thusa. Re tla sebetsa haufi-ufi le uena ho fana ka tharollo e sebetsang ka ho fetisisa e lumellanang le morero oa hau kapa litlhoko tsa sesebelisoa.

* OEM Diffusion Stone Le Carbonation Stone Materials

Ka lilemo tse fetang 18, HENGKO e khethehile tlhahiso eaSintered Metal Filters, ho iponahatsa e le khoebo e ka sehloohong tšimong. Kajeno, ka boikhohomoso re fana ka lisebelisoa tsa boleng bo phahameng tse kenyelletsang, empa ha li felle feela, mefuta e fapaneng ea 316 le 316L Stainless Steel, Bronze, Inconel Nickel, hammoho le khetho ea Lisebelisoa tse Kopantsoeng.

* OEM Diffusion Stone Le Carbonation Stone Ka Pore Size

Ho fihlela phello e nepahetseng ea ho hasana, mohato oa pele ke ho khetha asintered diffusion stonee nang le lesoba le nepahetseng. Khetho ena e lokela ho lumellana le litlhoko tsa hau tsa tekheniki. Haeba u na le lipotso mabapi le khetho ea boholo ba pore bakeng sa lejoe la phallo, ikutloe u lokolohile ho ikopanya le rona.

* OEM Diffusion Stone Le Carb Stone Ka Moralo

Ha ho tluoa ho moralo oa botle le boholo, hajoale re fana ka likhetho tse robeli tse fapaneng tseo u ka khethang ho tsona. Mefuta ea rona e kenyelletsa majoe a bonolo a aeration a nang le lihokelo tsa inlet, mefuta e fapaneng e nang le likhoele tse fapaneng, lisekoere le libopeho tse ling tse tloaelehileng, hammoho le khetho ea ho etsa libopeho tse ikhethileng. Ho sa tsotelehe litlhoko tsa hau, re ikemiselitse ho fana ka litlhoko tsohle tsa hau tsa OEM le ho fana ka tharollo e lokiselitsoeng.

SFB Series Aeration Stone

SFC Series Aeration Stone

SFH Series Aeration Stone

SFW Series Aeration Stone

Multi-joint Diffusion Stone for Bioreactor

Lejoe la Phatlalatso ea Moqapi oa disc

Mushroom Head Shape Aeration Stone

Phapang e Khethehileng ea OEM bakeng sa Sefate sa Semiconductor

* OEM Diffusion Stone Le Carbonation Stone Ka kopo

Majoe a rona a sintered metal diffusion le lisebelisoa tsa carbonation li etselitsoe ho ntlafatsa ts'ebetso ea sistimi ea aeration lits'ebetsong tsa hau tsa indasteri. Likarolo tsena tsa sparger, tse entsoeng ka tšepe e sa hloekang ea 316L, li fana ka thepa ea boleng bo holimo joalo ka ho hanyetsa kutu, li-acids le alkalis, hammoho le sebopeho se tiileng le se tsitsitseng. Ho sa tsotellehe hore na kopo ea hau kapa morero ke ofe, u se ke ua tsilatsila ho iteanyaHENGKObakeng sa lintlha tse qaqileng.

* Hobaneng u Khetha HENGKO OEM Lejoe la Hao la Phallo le Lejoe la Carbonation

HENGKO e eme e le moetsi ea ikhethang le ea nang le boiphihlelo oa majoe a phallo le carbonation, a sebelisoang ho pholletsa le makala a mangata joalo ka lijo le lino, meriana le kalafo ea metsi.

Ka tlase ke a mang a mabaka a bohlokoa a hore HENGKO e ka ba molekane oa hau ea loketseng oa OEM bakeng sa ho fumana phallo le majoe a carbonation:

1. Boleng bo Phahameng ba Sehlahiswa:

HENGKO e ikemiseditse ho qapa majwe a diffusion le carbonation a kopanang kapa a fetang ditlwaelo tsa indasteri.

Ka ho sebelisa lisebelisoa tsa maemo a holimo le mekhoa e tsoetseng pele ea tlhahiso, re netefatsa hore lihlahisoa tsa rona lia tšoarella, li sebetsa hantle ebile lia sebetsa.

2. Likhetho tse Lokisitsoeng:

Re fana ka mefuta e mengata e fapaneng ea khetho ea hau ho khotsofatsa litlhoko tsa hau tse ikhethileng.

Linyehelo tsa rona li kenyelletsalisebelisoa tse fapaneng, boholo ba pore, libopeho, le boholo. Ho feta moo, re fana ka liphutheloana tsa motho ka mong

le lits'ebeletso tsa ho ngola ho ntlafatsa ponahalo ea lebitso la hau.

3. Leano la Phalisano la Litheko:

Ho leka-lekanya boleng ba premium le ho baballa litšenyehelo, lihlahisoa tsa HENGKO tsa tlholisanoetsa khetho eo re e ratang

bakeng sa likhoebo tse batlang boleng ba chelete. Re fana ka litheolelo ka liodara tse ngata 'me re ikemiselitse ho sebelisanale uena ho rera

leano la litheko le tsamaellanang le mathata a hau a tekanyetso.

4. Tšebeletso e Hlollang ea Bareki:

HENGKO e ithorisa ka sehlopha se nang le litsebo tsa baemeli, ba tsebang ho u tataisa ka khetho ea lihlahisoa,

customization, le ho fana ka tšehetso ea tekheniki. Sehlopha sa rona se ikemiselitse ho fana ka maikutlo a potlakileng le a arabelang

tšebeletso ho netefatsa khotsofalo ea hau.

5. Phano e Potlakile:

Ka lebaka la marangrang a pharalletseng a thepa a lefats'e a HENGKO, re khona ho tlisa lihlahisoa tsa rona

ka bokgabane le ka potlako. Re boetse re fana ka thepa e potlakileng le mekhoa e meng ea ho fana ho fana ka eona

ho tsa haoditlhoko tse itseng.

Qetellong, HENGKO e eme e le mofani ea tšepahalang le ea ka tšeptjoang oa phallo lemajoe a carbonation.

Re ikemiselitse ho u thusa ho ntlafatsa boleng ba sehlahisoa sa hau le ho sebetsa hantle.

* Eo Re sebelitseng le rona

Ka boiphihlelo bo bongata ba ho rala, ho nts'etsapele le ho hlahisali-filters tse sintered, HENGKO e thehile litšebelisano tse tšoarellang le liunivesithi tse ngata tse tummeng le lilaboratori tsa lipatlisiso libakeng tse fapaneng. Haeba u batla li-filters tse ikhethileng, u se ke oa tsilatsila ho ikopanya le rona. HENGKO, re ikemiselitse ho u fa tharollo e nepahetseng ea ho sefa e sebetsanang le litlhoko tsohle tsa hau tsa ho sefa.

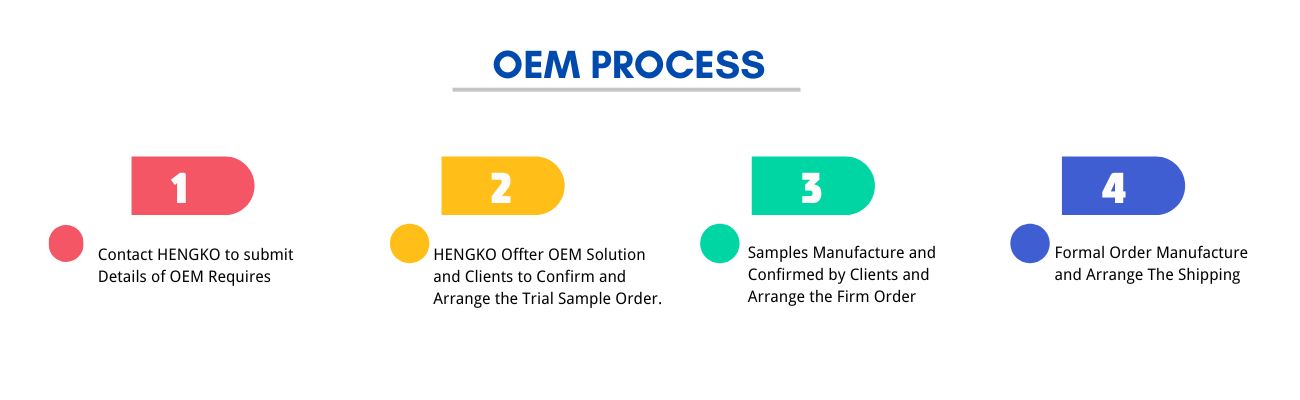

* Seo U Lokelang ho se Etsa ho OEM Diffusion Stone le Carbonation Stone- OEM Process

Haeba u na le mohopolo kapa mohopolo bakeng sa moetloOEM Sintered Carbonation Stone, re u mema ka mofuthu hore u ikopanye le sehlopha sa rona sa thekiso ho buisana ka merero ea hau ea moralo le litlhaloso tsa tekheniki ka botlalo. Ho fumana leseli mabapi le ts'ebetso ea rona ea OEM, ka kopo sheba lintlha tse latelang. Re ts'epa hore e tla thusa tšebelisano e se nang moeli pakeng tsa rona.

* FAQ mabapi le Diffusion Stone le Carb Stone?

Joalo ka Latelang ke tse ling tsa FAQ mabapi le tšepe e entsoeng ka tšepe ea Carbonation Stone hangata e botsoang, ke tšepa hore li tla thusa.

Re romelle molaetsa oa hau:

Sintered metal diffusion stone ke sesebediswa se senyane, se nang le masoba se sebedisetswang ho hasanya digase kapa maro ka setshelong se seholoanyane. E entsoe ka ho futhumatsa le ho kopanya phofo ea tšepe ho fihlela e etsa karolo e tiileng e nang le masoba a manyenyane a limilione a hokahaneng. Li-pores tsena li lumella khase kapa mokelikeli o lakatsehang hore o fete ka har'a lejoe ebe o hasana tikolohong e potolohileng ka mokhoa oa li-bubble tse ntle kapa marotholi.

Mona ke tse ling tsa litšobotsi tsa bohlokoa tsa majoe a sintered metal diffusion:

- Boitsebiso: Hangata e entsoe ka tšepe e sa hloekang, haholo-holo kereiti ea 316, e tsejoang ka ho tšoarella ha eona le ho hanyetsa kutu. Majoe a mang a ka etsoa ka litšepe tse ling joalo ka titanium kapa boronse ho latela litlhoko tse ikhethang tsa kopo.

- Porosity: Majoe a fapaneng a na le boholo bo fapaneng ba pore, bo lekantsoeng ka li-microns, tse amang boholo le sekhahla sa phallo ea li-bubble kapa marotholi a qhalakaneng. Li-pores tse nyane li hlahisa lipululana tse ntle haholo, tse loketseng lits'ebetso tse hlokang maemo a holimo a ho monya khase, joalo ka setoto sa oksijene ha ho riteloa biri.

- Lisebelisoa: Li sebelisoa liindastering tse fapaneng:

- Ho ritela: Biri e nang le carbonate le cider, wort ea oksijene.

- Pharmaceuticals: Phallo ea khase e hloekisitsoeng bakeng sa tlhahiso ea lithethefatsi.

- Biotechnology: Litloaelo tsa lisele tse oksijene bakeng sa libaktheria le kholo ea tomoso.

- Ho sebetsa ka lik'hemik'hale: Ho kenya moea ka har'a litanka le li-reactors.

- Phekolo ea metsi: Phallo ea ozone kapa oksijene bakeng sa ho bolaea likokoana-hloko.

- Phekolo ea metsi a litšila: Phallo ea moea bakeng sa moea le kholo ea baktheria.

Majoe a phallo ea tšepe ea sintered a fana ka melemo e mengata ho feta lisebelisoa tse ling:

- Durability: Li matla ebile li khona ho mamella likhatello tse phahameng le mocheso o tloaelehileng lits'ebetsong tsa indasteri.

- Khanyetso ea lik'hemik'hale: Kaho ea tšepe e sa hloekang e etsa hore e se ke ea senyeha ho tsoa lik'hemik'hale tse ngata le lisebelisoa tsa ho hloekisa.

- Uniformity: Ts'ebetso ea sintering e laoloang e tiisa hore kabo ea boholo ba pore e tsitsitse, e lebisang ho khase e ts'oanang ea khase / ho hasana ha metsi.

- Ho hloekisa habonolo: Sebaka sa tsona se boreleli le li-pores tse bulehileng li thusa ho hloekisa habonolo le ho thibela likokoana-hloko.

Haeba u na le lipotso tse ling mabapi le ts'ebeliso e khethehileng kapa likarolo tsa majoe a sintered ka tšepe, ikutloe u lokolohile ho botsaHENGKO! re thabela ho tebela ka botebo ts'ebetsong le melemo ea bona.

Lejoe la carb, le tsejoang hape e le lejoe la carbonation, ke mofuta oa lejoe la tšepe le silafetseng le etselitsoeng lino tse tahang, haholo-holo biri le cider. E sebetsa ka ho tšela khase ea carbon dioxide (CO2) ka har'a mokelikeli ka li-pores tsa eona tse nyane, ho etsa lipulunyana tse ntle ho pholletsa le seno. Li-bubble tsena ebe lia qhibiliha butle-butle, e leng se hlahisang fizz le carbonation tse tloaelehileng tseo re li thabelang ka har'a lino tsa rona.

Mona ke lintlha tsa bohlokoa mabapi le majoe a carb:

- Material: Hangata e entsoe ka tšepe e sa hloekang e entsoeng ka sintered, joalo ka majoe a mang a phanoang, ka lebaka la ho tšoarella ha eona le ho hanyetsa ho bola.

- Sebopeho le Boholo: Hangata ke cylindrical, e nang le bolelele le bophara bo fapaneng ho latela ts'ebeliso e reriloeng le boholo ba tanka.

- Mosebetsi: Li kenngoa ka har'a tanka ea seno, hangata haufi le tlase, 'me khase ea CO2 e kenngoa lejoeng tlas'a khatello. Li-pores li lumella CO2 ho feta le ho hasana joalo ka lipululoana tse nyane ho pholletsa le mokelikeli, ka mokhoa o hlakileng o fafatsa seno.

- Melemo: Ha ho bapisoa le mekhoa e meng ea carbonation, majoe a carb a fana ka melemo e mengata:

- Controlled carbonation: Taolo e nepahetseng holim'a boemo ba carbonation ka ho fetola khatello ea CO2.

- Phatlalatso e tšoanang: Li-bubble tse ntle li netefatsa ho ajoa ha CO2 ho pholletsa le seno.

- Bonolo ba carbonation: E fokotsa moferefere le ho thehoa ha foam ha o ntse o fumana carbonation e lakatsehang.

- E na le litšenyehelo: E batla e le theko e tlaase ha e bapisoa le mekhoa e meng.

- Lisebelisoa: Le hoja li sebelisoa haholo-holo bakeng sa biri le cider carbonation, li ka boela tsa sebelisoa bakeng sa:

- Oxygenating wort: Pele ho belisoa ha ho riteloa, ho khothalletsa kholo ea tomoso e phetseng hantle.

- Ho eketsa CO2 ho lino tse bataletseng kapa tse ka tlaase ho carbonated: Bakeng sa ho kenya libotlolong kapa ho kegging.

- Ho hloekisa oksijene e qhibilihisitsoeng: Ka metsing kapa lino tse ling, haeba ho hlokahala hore ho tlosoe oksijene.

Leha ho le joalo, majoe a carb a boetse a na le mathata a mang:

- Ho koala: Li-pores li ka koaleha ha nako e ntse e ea ka sediment ea tomoso kapa liprotheine, tse hlokang ho hloekisoa khafetsa le ho hloekisoa.

- Tlhokomelo: Ho beha leihlo khatello ea CO2 le ho etsa bonnete ba hore lejoe le behoa bakeng sa ho hasana hantle ho bohlokoa.

- Tšilafalo e ka bang teng: E hloka mekhoa e nepahetseng ea bohloeki ho qoba tšoaetso ea baktheria.

Ka kakaretso, majoe a carb ke sesebelisoa se tummeng le se sebetsang bakeng sa ho fumana carbonation e tsitsitseng le e laoloang ka lino tse tahang, haholo-holo ho etsoa ka lapeng le li-breweries tse nyenyane. Bonolo ba bona ba ts'ebeliso, ho khoneha, le bokhoni ba ho hlahisa lipululana tse ntle, tse boreleli li li etsa letlotlo la bohlokoa bakeng sa bahlahisi ba ritelo le bahlahisi ba lino.

Ke tšepa hore sena se hlakisa karolo ea majoe a carb lefats'eng la seno sa carbonation! Haeba u na le lipotso tse ling kapa u lakatsa ho tseba haholoanyane ka likarolo tse itseng tsa tšebeliso ea tsona, ikutloe u lokolohile ho botsa.

Majoe a tšelang tšepe a sirelelitsoeng a fana ka melemo e mengata ho feta lisebelisoa tse ling tse kang lirafshoa kapa polasetiki, e leng se etsang hore e be khetho e tsebahalang liindastering tse fapaneng. Melemo e meng ea bohlokoa ke ena:

Nako e telele:Sintered metal e matla ka mokhoa o makatsang mme e khona ho mamella likhatello tse phahameng le mocheso, tse atisang ho kopana le lits'ebetso tsa indasteri. Sena se fetolela nako e telele ea bophelo ha e bapisoa le lisebelisoa tse senyehang habonolo joalo ka majoe a ceramic.

Ho hanyetsa lik'hemik'hale: Tšepe e sa hloekang e sebelisoang ka majoe a mangata a tšepe a sintered e hanyetsa haholo ho bola ho tsoa ho mefuta e mengata ea lik'hemik'hale le lisebelisoa tsa ho hloekisa. Sena se etsa hore e be tse loketseng ho sebelisoa libakeng tse thata kapa ka maro a mabifi.

Uniformity:Ho fapana le lisebelisoa tse ling, tšepe e sirelelitsoeng e lumella taolo e nepahetseng holim'a kabo ea boholo ba pore nakong ea ts'ebetso ea tlhahiso. Sena se netefatsa phallo e tsitsitseng ea khase kapa mokelikeli, e lebisang ts'ebetsong e nepahetseng le ho fokotsa litšila.

Katleho:Sebopeho sa pore sa junifomo le se bulehileng sa majoe a tšepe a sintered se fokotsa ho hanyetsa khase kapa phallo ea metsi. Sena se fella ka ho hasana hantle le ho fokotsa tšebeliso ea khase ha e bapisoa le lisebelisoa tse sa sebetseng hantle.

Ho hloekisa habonolo:Sebaka se boreleli le li-pores tse bulehileng tsa majoe a tšepe a sintered li thusa ho hloekisa habonolo le ho etsa sterilization. Sena se bohlokoa bakeng sa ho boloka bohloeki le ho thibela ho koaloa ha lisebelisoa tse kenyelletsang lijo kapa meriana.

Boholo bo laolehang ba pore:Lisebelisoa tse fapaneng li hloka boholo bo fapaneng ba pore bakeng sa phallo e nepahetseng. Sintered metal e lumella ho hokahanya boholo ba pore ho latela litlhoko tse ikhethileng, ho ntlafatsa ts'ebetso bakeng sa likhase tse fapaneng, lino le likhahla tsa phallo.

Mefuta-futa:Majoe a nang le tšepe ea sintered a loketse mekhoa e mengata ea liindasteri tse fapa-fapaneng, ho tloha ho ritelo le meriana ho ea ho phekolo ea metsi a litšila le ho sebetsana le lik'hemik'hale.

Melemo e meng:

- Ho hanyetsa mocheso: Li khona ho mamella mocheso o phahameng, ho etsa hore li tšoanele metsi a chesang kapa ho hasana ha khase ka mocheso o phahameng.

- Sebaka se se nang thupa: Sebaka sa tsona se boreleli se fokotsa kotsi ea ho bokellana kapa ho koala ha masala.

- E na le botsoalle tikolohong: Li tšoarella nako e telele 'me li phela nako e telele, li fokotsa litšila ha li bapisoa le mekhoa e meng e ka lahloang.

Ka kakaretso, majoe a silafalitsoeng a tšepe a fana ka motsoako o atlehang oa ho tšoarella, ho sebetsa hantle, le ho feto-fetoha ha maemo, a ba etsa sesebelisoa sa bohlokoa liindastering tse ngata.

Haeba u na le ts'ebeliso efe kapa efe kelellong, nka batlisisa ka botebo hore na majoe a sintered a ka thusa litlhoko tsa hau joang. Ntsebise feela seo u se ratang!

Majoe a tšekang a tšepe a ka etsoa ho tsoa mefuteng e mengata ea litšepe, ho kenyeletsoa 316L tšepe e se nang tšepe, titanium le boronse.

Majoe a tšelang tšepe a sirelelitsoeng hangata a entsoe ka thepa e tšoarellang, e sa jeng e ka mamellang maemo a fapaneng a tikoloho le ho pepeseha ha lik'hemik'hale. Lisebelisoa tse tsebahalang haholo li kenyelletsa:

1. Ts'epe e sa beng le mabali

- Mephato:304, 316, le 316L tšepe e sa hloekang.

- Likaroloana:

- Khanyetso ea kutu.

- Ho tšoarella le matla.

- E babatsehang ho hanyetsa mocheso o phahameng.

- Ho lumellana le lisebelisoa tsa boleng ba lijo le lino.

- Lisebelisoa:

- Carbonation tlhahisong ea joala le seno.

- Aeration tsamaisong ea ho hloekisa metsi.

2. Titanium

- Likaroloana:

- Karolelano e phahameng ea matla ho boima.

- Khanyetso e ikhethang ea ho bola, haholo-holo libakeng tse mabifi.

- Ha e na chefo ebile e lumellana le lintho tse phelang.

- Lisebelisoa:

- Lisebelisoa tsa biomedical (mohlala, tsamaiso ea oksijene).

- Sebelisa lits'ebetsong tse thata tsa lik'hemik'hale.

3. Hastelloy (Nickel Alloy)

- Likaroloana:

- Khanyetso e phahameng ea kutu, haholo-holo libakeng tse nang le asiti le oxidative.

- Botsitso bo phahameng ba mocheso.

- Lisebelisoa:

- Ts'ebetso ea lik'hemik'hale le ea meriana.

- Libaka tse mabifi tsa indasteri.

4. Inconel (Nickel-Chromium Alloy)

- Likaroloana:

- Ho hanyetsa oxidation le corrosion mochesong o feteletseng.

- Matla a mochine tlas'a khatello e phahameng.

- Lisebelisoa:

- Aerospace le tsamaiso ea khase ea indasteri.

5. Boronse

- Likaroloana:

- Ho hanyetsa kutu e itekanetseng.

- E boloka chelete bakeng sa lisebelisoa tse khethehileng.

- Lisebelisoa:

- Lisebelisoa tse sa hlokeng letho la ho sefa le ho hasana.

6. Koporo

- Likaroloana:

- High thermal le motlakase conductivity.

- Lintho tsa tlhaho tsa antimicrobial.

- Lisebelisoa:

- Litsamaiso tse khethehileng tsa ho hasana ha khase le tsamaiso ea moea.

7. Monel (Nickel-Copper Alloy)

- Likaroloana:

- Ho hanyetsa ho hotle ha metsi a leoatle le maemo a acidic.

- Lisebelisoa:

- Lisebelisoa tsa metsing le tsa lik'hemik'hale.

Ntho e 'ngoe le e' ngoe e khethoa ho latela litlhoko tse khethehileng tsa kopo, tse kang ho lumellana ha lik'hemik'hale, mamello ea mocheso le matla a mochine. Tšepe e sa hloekang, haholo-holo 316L, ke thepa e sebelisoang ka ho fetisisa ka lebaka la ho feto-fetoha ha eona le ho boloka chelete e ngata.

Hangata majoe a carb a entsoe ka majoe a porous a kang sintered stainless steel kapa ceramic.

Majoe a tšelang tšepe a sirelelitsoeng hangata a beoa ka har'a sistimi ea ente ea khase ebe a qoelisoa ka har'a mokelikeli o lokelang ho phekoloa. Joale khase e kenngoa ka lejoe, e leng ho qhala khase mokelikeli.

Majoe a kentsoeng ka tšepe ea sintered ke lisebelisoa tse sebetsang ka tsela e fapaneng tse sebelisoang lits'ebetsong tse fapaneng moo likhase kapa maro a hlokang ho hasanngoa, ho tsoakoa kapa ho tšeloa moea. Sebopeho sa bona sa porous se lumella taolo e nepahetseng holim'a boholo le phallo ea li-bubble, e leng se etsang hore li atlehe haholo liindastering tse ngata.

Tšebeliso e Tloaelehileng ea Sintered Metal Diffusion Stones

1. Phallo ea Khase

- Tlhaloso:Ho arola likhase ka har'a maro ho fihlela motsoako o ts'oanang le o sebetsang hantle.

- Lisebelisoa:

- Indasteri ea ho ritela:

- Biri ea carbonate le soda ka ho hasa CO₂.

- Oxygenating wort nakong ea belisoa ho ntšetsa pele mosebetsi oa tomoso.

- Phekolo ea Metsi:

- Ho kenya moea ka metsi ho ntlafatsa boemo ba oksijene bakeng sa bophelo ba metsing.

- Ho kenya ozone bakeng sa tlhoekiso ea metsi.

- Chemical Processing:

- Ho arola likhase tse kang naetrojene kapa haedrojene ka har'a metsoako ea lik'hemik'hale.

- Indasteri ea ho ritela:

2. Aeration

- Tlhaloso:Ho kenya moea kapa oksijene ka har'a maro ho nolofatsa lits'ebetso tse joalo ka ho belisoa kapa tlhoekiso.

- Lisebelisoa:

- Ho belisoa tlhahisong ea lijo le seno.

- Phekolo ea metsi a litšila ho senya lisebelisoa tsa tlhaho.

3. Ho fokotsa Khase

- Tlhaloso:Ho ntša likhase tse qhibilihileng (mohlala, oksijene) marong ka ho hasanya khase e sa sebetseng joalo ka naetrojene kapa argon.

- Lisebelisoa:

- Ho tlosa lintho tse hlapollang kapa tse metsi ka lik'hemik'hale le tsa meriana.

- Ho hloekisa oksijene biri kapa veine ho thibela oxidation.

4. Ho kopanya le ho ferekana

- Tlhaloso:Ntlafatso ea ho kopanya likhase le metsi bakeng sa homogeneity.

- Lisebelisoa:

- Li-reactor tsa indasteri moo tšebelisano e nepahetseng ea mokelikeli oa khase e leng bohlokoa.

- Ho matlafatsa ts'ebetso ea lik'hemik'hale ka ho ntlafatsa likamano lipakeng tsa li-reactants.

5. Oksijene

- Tlhaloso:Ho qhalla oksijene ka har'a maro bakeng sa bophelo kapa lik'hemik'hale.

- Lisebelisoa:

- Ho matlafatsa kholo ea mekhoa ea temo ea metsing.

- Ts'ehetso ea ts'ebetso ea likokoana-hloko ho li-bioreactors kapa litsamaiso tsa manyolo.

6. Khabone

- Tlhaloso:Ho kenya carbon dioxide ka har'a lino ho etsa fizz.

- Lisebelisoa:

- Tlhahiso ea biri, soda le metsi a phatsimang.

- Kofi e khethehileng le lino-mapholi tsa nitro.

7. Tlhokomelo ea Tikoloho

- Tlhaloso:Ho fana ka lisampole tsa khase ho li-detectors kapa analyzer.

- Lisebelisoa:

- Teko ea tikoloho bakeng sa lintho tse silafatsang.

- Sampling ea khase mekhoeng e laoloang.

8. Likokoana-hloko le Meetlo ea Lisele

- Tlhaloso:Ho fana ka aeration e laoloang kapa oksijene ho media media.

- Lisebelisoa:

- Li-bioreactors bakeng sa kholo ea lisele.

- Mekhoa ea ho belisoa ha likokoana-hloko.

Melemo ea Sintered Metal Diffusion Stones

- Nako e telele:E hanyetsanang le corrosion le likhatello tse phahameng.

- Nepahetse:Saese e tšoanang ea pore e netefatsa tlhahiso e tsitsitseng ea bubble.

- Reusability:Ho bonolo ho hloekisa le ho hlokomela.

- Mefuta-futa:E lumellana le mefuta e mengata ea likhase le maro.

- Customizability:E fumaneha ka libopeho tse fapaneng, boholo, le limaraka tsa pore ho lumellana le litlhoko tse itseng.

Ka ho khetha thepa e nepahetseng le boholo ba pore, majoe a sintered a ka ntlafatsoa bakeng sa ts'ebeliso efe kapa efe ea tšebelisano ea metsi, aeration kapa khase.

Hangata majoe a carb a kenngoa ka sejaneng se nang le mokelikeli o lokelang ho ba carbonated, ebe carbon dioxide e kenngoa ka lejoe, le qhalang khase ka har'a metsi.

E, mefuta e 'meli ea majoe e ka hloekisoa ho sebelisoa mekhoa e sa tšoaneng, ho kopanyelletsa le ho ineloa ka har'a litharollo tsa ho hloekisa, ho belisoa le ho etsa autoclaving.

Nako ea bophelo easintered metal diffusion stoneslecarbonation (carb) majoeho itšetlehile ka lintlha tse 'maloa, ho kenyelletsa le thepa e sebelisoang, kopo, le hore na li hlokometsoe hantle hakae. Kakaretso ke ena:

Majoe a Sintered Metal Diffusion:

- Lintho tse bonahalang: Hangata e entsoe kats'epe e sa beng le mabali, Hastelloy, kapatitanium, majoe a tšepe a sintered a tšoarella haholo ebile ha a na kutu, e leng se tlatsetsang ho phela nako e telele.

- Bolele ba bophelo:

- Ka kakaretso, tsena li ka tšoarellalilemo tse 'maloa(hangata3-5 lilemokapa ho feta) haeba li hlokometsoe hantle.

- Bophelo ba bona bo bolelele bo susumetsoa keho hloekisa khafetsa, kgahlamelo ya dikhemikhale tse matla, mocheso, lemaemo a khatello.

- Lintlha Tse Amang Bophelo Bohle:

- Kaho ea sekhahla: Ha nako e ntse e ea, liminerale le likaroloana tse ling tsa mokelikeli li ka koala li-pores, tsa fokotsa katleho. Ho hloekisa khafetsa (mohlala, ho hloekisa ka ultrasonic kapa ho khutlela morao) ho ka lelefatsa bophelo ba bona.

- Khanyetso ea kutu: Litšepe tse sa hloekang le litšepe tse ling tse sebelisoang ka har'a majoe a sarolohang ha li bola, empa ho pepesetsoa litharollo tse nang le asiti e ngata haholo kapa tsa mantlha ho ka fokotsa nako ea tsona ea bophelo.

Majoe a carbonation:

- Lintho tse bonahalang: Hangata majoe a carbonation a entsoe ho tlohasintered stainless steelkapa lisebelisoa tse ling tse hananang le ho bola. Mosebetsi oa bona o ka sehloohong ke ho hasanya CO2 ka lino tse kang biri kapa metsi a phatsimang.

- Bolele ba bophelo:

- Nako e tloaelehileng ea bophelo e ka ba1-3 lilemobakeng sa ts'ebeliso ea khafetsa ho li-breweries kapa liindasteri tse ts'oanang, ho latela maemo a ts'ebeliso (mantsoe a CO2, mekhoa ea ho hloekisa, joalo-joalo).

- In lisebelisoa tse bobebe, li ka ’na tsa tšoarella nako e telele.

- Lintlha Tse Amang Bophelo Bohle:

- Ho koala le ho silafatsa: Ha nako e ntse e ea, liminerale kapa lintho tse phelang li ka koala li-pores tse ntle. Ho hloekisa ka mokhoa o nepahetseng ho sebelisoa mekhoa e nepahetseng (mohlala, ho hloekisa ka morao, ho hloekisa lik'hemik'hale) ho ka lelefatsa bophelo.

- Khatello le mocheso: Likhatello tse phahameng le mocheso li ka senya majoe a carbonation ka potlako, kahoo ho sebelisa mekhoa e nepahetseng ea ts'ebetso ho bohlokoa.

Litlhahiso tsa ho eketsa nako ea bophelo:

- Ho hloekisa kamehla: Ho hloekisa ka mekhoa e nepahetseng (mohlala, ho hloekisa ka ultrasonic, backflushing, kapa ho hlatsoa asiti) ho ka thusa ho thibela ho koala le ho bola.

- Poloko e nepahetseng: Ka mor'a ho sebelisoa, ho boloka majoe sebakeng se omileng, se hloekileng ho ka thusa ho qoba ho bola le ho hola.

- Maemo a nepahetseng a tšebeliso: Kamehla latela litataiso tsa moetsi bakeng sa khatello, mocheso, le CO2 ho qoba ho roala pele ho nako.

Che, majoe a sintered metal diffusion le majoe a carb a etselitsoe lits'ebetso tse fapaneng 'me ha a fetohe.

Majoe a tšelang tšepe le majoe a carb a sebelisoa liindastering tse fapaneng, ka likhetho tse ikhethileng tse ipapisitseng le mesebetsi ea tsona e ikhethang. Kakaretso ke ena:

Majoe a Sintered Metal Diffusion:

- General Industries:

- Ho sebetsa ka lik'hemik'hale: Ho kenella moeeng ha litanka le li-reactors, lik'hemik'hale tsa mokelikeli oa khase, phallo ea ozone bakeng sa ho bolaea likokoana-hloko.

- Phekolo ea metsi a litšila: Phallo ea moea bakeng sa aeration le kholo ea baktheria, oksijene bakeng sa kalafo ea seretse.

- Phekolo ea metsi: Phallo ea ozone kapa oksijene bakeng sa ho bolaea likokoana-hloko, ho tlosoa ha likhase tse qhibilihileng.

- Biotechnology: Litloaelo tsa lisele tsa oksijene bakeng sa baktheria le kholo ea tomoso, ho ntšoa ha khase ho tsoa ho bioreactors.

- Pheliso ea matla: Oksijene ea metsi a phepelo ea boiler ho fokotsa ho bola.

- Indasteri ea Lijo le Lino:

- Brewing: Oxygenating wort bakeng sa kholo ea tomoso, carboning biri le cider.

- Winemaking: Micro-oxygenation ya veine nakong ya ho tsofala.

- Phetoho ea lijo: Ho kenya moea oa litanka bakeng sa ho belisoa le ho bolokoa, ho ntša likhase tse sa batleheng marong.

Carb Stones (Haholo-holo bakeng sa Carbonation):

- Indasteri ea lino tse tahang:

- Biri le cider: Tšebeliso ea mantlha bakeng sa carbonating e phethiloeng biri le cider, ka bobeli khoebong le molemong oa ho pheha lapeng.

- Metsi a phatsimang: Metsi a nang le carbonate kapa a ka makotikoting.

- Lijo tse ling tse nang le carbonate: Soda, kombucha, seltzer, joalo-joalo.

Lintlha tse Eketsehileng:

- Le ha mefuta ena ka bobeli e sebelisa tšepe e sirelelitsoeng, majoe a carb a batla a le manyane mme a na le masoba a matle bakeng sa carbonation e sebetsang hantle.

- Liindasteri tse ling, joalo ka meriana le lik'hemik'hale tse ntle, li ka sebelisa majoe a khethehileng a sintered a nang le boholo bo laoloang ba pore bakeng sa litlhoko tse khethehileng tsa phallo ea khase.

- Ho feto-fetoha ha majoe a tšepe a sintered ho lumella ho ikamahanya le litlhoko tse fapaneng, ho atolosa lisebelisoa tsa bona tse ka sebelisoang ho pholletsa le liindasteri tse fapaneng.

Haeba u ka rata ho tseba haholoanyane ka tšebeliso e khethehileng ea majoe ana indastering efe kapa efe, ikutloe u lokolohile ho botsa! Ke thabela ho tebela ka botebo lits'ebetsong tsa bona tse fapaneng.

* U ka boela ua rata

HENGKO e fana ka mefuta e mengata e pharalletseng ea Sintered Metal Diffusion le Carbonation Stones, hammoho le lihlahisoa tse ling tsa sintered filthara bakeng sa lits'ebetso tse fapaneng. Ka kopo sheba li-filters tse latelang tse sintered. Haeba sehlahisoa sefe kapa sefe se hapa thahasello ea hau, ikutloe u lokolohile ho tobetsa sehokelo ho bala lintlha tse ling. U boetse u amohelehile ho ikopanya le rona hoka@hengko.combakeng sa lintlha tsa litheko kajeno.