-

Tlhoekiso ea biopharmaceutical le ho hloekisa poleiti ea porous filthara 10um 20um 50um

Letlapa le nang le porous filthara ke mofuta o mocha oa lisebelisoa tse phahameng tse sebetsang hantle tse entsoeng ka tšepe e sa hloekang ka phofo ka sieving ea phofo, ho bopa, sinterin...

Sheba lintlha -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis le Galvanic CorrosionE Fokotsa Tšitiso ea RF 'me E Ntlafatsa Ts'ebetso ea Elektronike Kamohelo e betere bakeng sa lisebelisoa tsa hau tsa GPS, boemo ba leholimo ...

Sheba lintlha -

Sintered metal round deep filter sheets bakeng sa tlhahiso ea oli ea cannabis

Filtration Ho hlahisoeng ha lihlahisoa tse tsitsitseng tsa cannabinoid ho sefa ke mohato oa bohlokoa. Ho tlosa boka, mafura le oli ho tloha mariha a mangata ...

Sheba lintlha -

Sefe ea tšepe e sa hloekang ea Porous Metal Sheets SS316 Filter bakeng sa Phallo ea Khase ea Hydrogen

Sefa sa Metal Sheets ea Stainless SS316 bakeng sa Phallo ea Khase ea Hydrogen Notlolla ho Fetoha ha Lintho tse Sintered Metal ka HENGKO! Meta ea rona e sirelelitsoeng ...

Sheba lintlha -

Leqephe la Phatlalatso ea Khase bakeng sa li-MEA, tšepe e sa hloekang e entsoeng ka tšepe e entsoeng ka sintered / terata ...

Lipoleiti tsa filthara tsa tšepe tse sa hloekang tsa HENGKO li entsoe ka thepa ea phofo ea 316L ea sintering kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng. Ba bile...

Sheba lintlha -

Multi-layer sintered stainless stainless steel mesh plate fluidized bed equipment Distributor bot...

Letlapa la tšepe e sa hloekang bakeng sa bethe ea mokelikeli Taolo ea kabo ea khase, phetisetso ea thepa e phofshoana, le ts'ebetso ea fluidization e se e sebelisoa haholo ho ...

Sheba lintlha -

316 304 poleiti ea tšepe e sa hloekang - Sintered porous metal filter media osele

Li-filters tsa tšepe tse sa hloekang tsa HENGKO li entsoe ka thepa ea phofo ea sintering 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng. Ba bile...

Sheba lintlha -

Corrosion manganga microns 316L tšepe e sa jeleng paate porous sintered filthara lishiti tsa tšepe / ...

Hlalosa Sehlahisoa Likarolo tsa HENGKO tsa porous metal diffusion ke khetho e ka sehloohong bakeng sa ts'ebetso e phahameng ea electrolyzer le lisebelisoa tsa lisele tsa mafura. Uniform po...

Sheba lintlha -

Easy Clean Micron Porous SUS Sintered 316L Stainless Steel Inline Metal Sheet Plate Rou...

Lipampiri tsa tšepe tse sintered tse nang le porosity e phahameng li ile tsa fumanoa ho tloha mefuteng ea tšepe ka mekhoa ea ho hasana ea mahala e lateloang ke sintering. Sebopeho sa sintered ...

Sheba lintlha -

0.2 5 10 40 Micron porous sintered phofo tšepe e sa hloekang 316L tšepe poleiti filtara bakeng sa c...

Lisebelisoa tse nang le porous sintered plates tse fumanoang ka mekhahlelo ka ho hasana mahala, compaction, le sintering metallic powders li sebelisoa e le semi-sehlahisoa ho fumana ...

Sheba lintlha -

Customized 2 10 20 60 Micron Porous Sintered Stainless Steel 316L Metal Plate Filter

Maqephe a tebileng a filthara a sebelisoa ho tlosa likaroloana tsa maro. Sena se bolela hore maro a ka hloeka, a hloekile kapa a sefuoa. Maqephe a sefa a loketse...

Sheba lintlha -

5 10 30 60 90 microns phofo micro porous sintered lakane filtara

Sintered metal filter sheets e sebelisoa haholo bakeng sa ho tlosa likaroloana tsa kantle ho mefuta e mengata e fapaneng ea phallo ea litaba. Libaka tse kholo tsa ts'ebeliso: Likhase tse akaretsang,...

Sheba lintlha -

HENGKO sintered stainless steel 316 porous metal diffusion layers filters for ...

HENGKO stainless wire mesh plate plate e entsoe ka likarolo tse ngata tsa terata e lohiloeng hammoho ka mokhoa oa sintering. Mokhoa ona...

Sheba lintlha -

316 316L terata letlooeng la mesh poleiti e ngata / filthara ea disc...

Lifilimi tsa HENGKO sintered wire mesh li na le likarolo tse 5 tsa terata tse sirelelitsoeng tse nang le meaho e ikemetseng bakeng sa matla a mochini o matla le mocheso o phahameng...

Sheba lintlha -

Uniform matla sintered porous metal micron filter fluidizers bronze koporo koporo fil...

Maqephe a tebileng a filthara a sebelisoa ho tlosa likaroloana tsa maro. Sena se bolela hore maro a ka hloeka, a hloekile kapa a sefuoa. Maqephe a sefa a loketse...

Sheba lintlha -

Taolo ea phallo le kabo ea mokelikeli sintered filthara poleiti/lakane, phofo sintered porous...

Maqephe a tebileng a filthara a sebelisoa ho tlosa likaroloana tsa maro. Sena se bolela hore maro a ka hloeka, a hloekile kapa a sefuoa. Maqephe a sefa a loketse...

Sheba lintlha -

Porous metal sintered porous bronze filter plates/sheet bakeng sa phallo le taolo ea molumo

Maqephe a tebileng a filthara a sebelisoa ho tlosa likaroloana tsa maro. Sena se bolela hore maro a ka hloeka, a hloekile kapa a sefuoa. Maqephe a sefa a loketse...

Sheba lintlha -

porous tšepe filthara disc sekwere strainer micron sintered boro filtara lakane

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

hepa sintered boronse tšepe e sa hloekang letlapa le nang le porous metal filter bakeng sa mochini o hloekisang moea / oli

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

Custom sintered powder metal fitler sheet microns porosity bronze filter sheets for wat...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha

Lintlha tse ka sehloohong tsa Porous Metal Plate:

Likarolo tse ka sehloohong tsa maqephe a tšepe a porous li kenyelletsa:

1.High Durability:

Maqephe a tšepe a entsoe ka thepa e matla joalo ka tšepe e sa hloekang, titanium kapa li-alloys tsa nickel,

ho fana ka matla a babatsehang a mochine le ho hanyetsa ho bola, ho apara, le mocheso o phahameng.

| Lintho tse bonahalang | Matla a Mechini | Khanyetso ea Corrosion | Apara Resistance | Ho hanyetsa Mocheso | Lisebelisoa |

|---|---|---|---|---|---|

| Ts'epe e sa beng le mabali | Phahameng | Phahameng | Phahameng | E ntle haholo (ho fihlela ho 800 ° C) | Ho hloekisa, ho sebetsa ka lik'hemik'hale, oli le khase, meriana |

| Titanium | Mahareng | Holimo Haholo | Mahareng | E ntle haholo (ho fihlela ho 600 ° C) | Sepakapaka, tikoloho ea leoatle, lisebelisoa tsa bongaka |

| Lisebelisoa tsa Nickel | Holimo Haholo | E kgabane | Phahameng | E phahameng (ho fihlela ho 1000°C) | Filtration ea mocheso o phahameng, ts'ebetso ea lik'hemik'hale, tlhahiso ea matla |

2.Precise Filtration Control:

Boholo bo laoloang ba pore le ho ajoa ha junifomo ho lumella ho sefa ho nepahetseng, ho fana ka mokhoa o tsitsitseng

tshebetso ho pholletsa le mefuta e fapaneng ya ditshebediso.

3.Customizable Porosity:

Lishiti tsa tšepe tse nang le porous li ka etsoa ho latela boholo ba pore, sebopeho,

le ho ajoa, ho fana ka phetoho ea maemo ho finyella litlhoko tse khethehileng tsa ho hloekisa kapa ho phalla.

4.High Permeability:

Ho sa tsotellehe matla a bona, lipampiri tsa tšepe tse nang le porous li lumella ho phunyeletsa ho phahameng, ho netefatsa

litekanyetso tse sebetsang hantle tsa ho phalla ha likhase le lino tse metsi ha li ntse li boloka ts'ebetso ea ho sefa.

5.Ho lumellana ha Lik'hemik'hale:

Lipampiri tsena li lumellana le mefuta e mengata ea lik'hemik'hale, ho li etsa

e loketseng bakeng sa ho sebelisoa libakeng tse thata, ho kenyeletsoa ho sebetsa ha lik'hemik'hale le liindasteri tsa meriana.

6.Mocheso le Khatello Resistance:

Lisebelisoa tse sebelisoang ka maqephe a tšepe a porous li ka mamella ho feteletseng

mocheso le likhatello, ho netefatsa botsitso le ho tšepahala lits'ebetsong tse hlokang.

7.Tlhokomelo e tlase le nako e telele ea bophelo:

Lishiti tsa tšepe tse nang le porous li tšoarella haholo ebile ha li khone ho koala,

ho fokotsa tlhokahalo ea ho hlokomeloa khafetsa le ho nchafatsoa, ka hona ho lelefatsa bophelo ba bona ba ts'ebeletso.

8.Thermal le Motlakase Conductivity:

Ntle le ho sefa, maqephe a tšepe a porous a ka boela a sebetsa e le mocheso

le li-conductors tsa motlakase, ho atolosa mefuta ea tsona ea ts'ebeliso.

Likarolo tsena li etsa hore maqephe a tšepe a porous a loketse lits'ebetso tsa ho sefa, taolo ea phallo, litšehetso tsa li-catalyst,

le mekhoa ea karohano liindastering tse fapaneng, joalo ka sefofane, ts'ebetso ea lik'hemik'hale, meriana,

le boenjiniere ba tikoloho.

Mefuta ea Metal Sheet?

Ha e le hantle, ho na le mefuta e 'meli e meholo ea lishiti tsa tšepe tseo u ka li fumanang

'marakeng oa letlapa le nang le porous :

1. Matlapa a sintered:

Tsena li entsoe ka compacting le sintering tšepe phofo. Hangata, li-pores tse maqepheng ana

e hokahaneng ebile e ka fapana ka boholo le sebopeho. Lipampiri tsa tšepe tse sirelelitsoeng hangata li sebelisoa lits'ebetsong

moo ho hlokahalang matla a phahameng le tlhoekiso e ntle, joalo ka lifilthara, li-heaters tsa mocheso, le lisebelisoa tse fokotsang molumo.

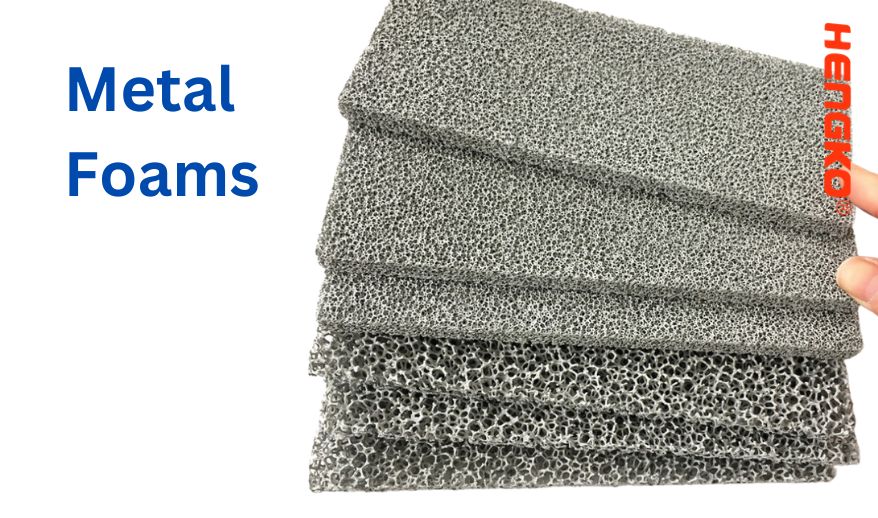

2. Metal Foams:

Metal foams e entsoe ka ho kenya lipululana tsa khase ka har'a tšepe e qhibilihisitsoeng le ho e lumella hore e tiee.

Li-pores tse maqepheng ana hangata li koalehile, ho bolelang hore ha li kopane. Metal foams ke

e sebelisoang hangata lits'ebetsong moo ho hlokahalang matla a bobebe le a phahameng, joalo ka sebakeng sa sefofane le

lisebelisoa tsa likoloi.

Mona ke mefuta e meng ea lishiti tsa tšepe tse porous:

1. Mesh ea terata e lohiloeng:

Mofuta ona oa letlowa o etsoa ka ho loha hammoho lithapo tse tšesaane. Boholo ba pore ka letlooeng le lohiloeng

e ka laoloa ke boholo ba lithapo le mokhoa oa ho loha. Mesh ea terata e lohiloeng hangata

e sebelisoang lits'ebetsongmoo ho hlokehang ho sefa le thepa e ntle ea phallo, joalo ka li-skrini le li-filters.

2. Tšepe e atolositsoeng:

Mofuta ona oa lakane o entsoe ka ho petsola lesela le tiileng la tšepe ka mokhoa o itseng ebe oa le otlolla.

Li-pores tsa tšepe e atolositsoeng hangata li telele ebile li bōpehile ka daemane. E atolositsoeng tšepe hangata

e sebelisoang lits'ebetsongmoo ho hlokahalang boima bo bobebe le matla a matle, joalo ka balebeli ba tšireletso le litselana tsa maoto.

Tšebeliso ea Sintered Porous Metal Sheet

Sintered porous metal sheets ke mecha ea phatlalatso e feto-fetohang ka lebaka la thepa ea eona e ikhethang.

Mona ke tse ling tsa lisebelisoa tseo u ka li sebelisang:

* Tikoloho ea Mocheso o Phahameng:

* Tikoloho e thata ea lik'hemik'hale:

* Lisebelisoa tsa khatello e phahameng:

* Tlhokahalo ea Taolo e Nepahetseng ea Karolo:

* Reusability le Regenerability:

Hape Mona ho na le liindasteri tse ka ruang molemo ka ho khetheha ka ho sebelisa lishiti tsa tšepe tse sintered ka har'a lits'ebetso tsa tsona tsa ho sefa.

o ka hlahloba hore na e tla ba hantle bakeng sa sistimi kapa sesebelisoa sa hau?

* Ts'ebetso ea Lik'hemik'hale - Bakeng sa ho sefa metsi le likhase tse senyang, le li-catalysts ho tsoa melapong ea tšebetso.

* Pheliso ea Motlakase - Ho hloekisa ka mocheso o phahameng oa likhase ka lifemeng tsa motlakase.

* Indasteri ea Meriana - Ho netefatsa bohloeki le bohloeki ba lihlahisoa ka ho tlosa libaktheria le likaroloana.

* Indasteri ea Lijo le Lino - Filtration bakeng sa ho hlakisa lino, le ho tlosa likaroloana tse sa batleheng.

* Phekolo ea Metsi - Ho kenya letsoho lits'ebetsong tsa tlhoekiso ka ho tlosa litšila metsing.

Ka kakaretso, maqephe a sintered porous metal ke sesebelisoa sa bohlokoa bakeng sa lits'ebetso tsa ho sefa liindasteri tse hlokang ho tšoarella, ho hanyetsa mocheso o phahameng, ho sefa ka nepo, le ho sebelisoa hape.

LBH

1. Ke eng aletlapa la tšepe le porous, ’me e etsoa joang?

Letlapa la tšepe le nang le porous ke mofuta oa thepa e khetholloang ke sebopeho sa eona se phunyeletsang, se entsoeng ka

masoba a hokahaneng kapa mahlaku ho pholletsa le boima ba ona. Lipampiri tsena li hlahisoa ka ho khetheha

mokgoa o tsejoang ka hore ke sintering. Sintering e kenyelletsa ho kopanya phofo ea tšepe ka har'a hlobo ebe e futhumatsa

e ka tlase ho ntlha ya yona e qhibidihang. Phekolo ena ea mocheso e etsa hore likaroloana tsa tšepe li kopane ntle le ho qhibiliha,

ho theha sebopeho se tiileng se nang le porosity e laolwang hantle.

Mokhoa ona o lumella ho etsoa ha maqephe a nang le boholo bo fapaneng ba pore, libopeho le kabo,

e etselitsoeng lisebelisoa tse khethehileng. Lipampiri tsa tšepe tse sa hloekang, mohlala, li sebelisoa haholo ka lebaka la

thepa ea bona e babatsehang ea mechine, ho hanyetsa kutu, le botsitso ba mocheso.

2. Lisebelisoa tse ka sehloohong tsa lishiti tsa tšepe tse sa hloekang ke life?

Lishiti tse entsoeng ka tšepe tse sa hloekang li sebelisoa mefuteng e mengata ea lisebelisoa ka lebaka la ho feto-fetoha ha tsona le ho tšoarella ha tsona.

Tse ling tsa lisebelisoa tsa bohlokoa li kenyelletsa:

* Filtration:

E sebelisoa ka bobeli tsamaisong ea khase le ea metsi, e tlosa lintho tse itseng ka katleho

ka lebaka la boholo ba tsona bo nepahetseng ba pore.

* Ho sesa le ho ferekana:

E loketse karabelo ea mokelikeli oa khase, aeration, le lits'ebetsong tsa ho ritela,moo ho laoloang

boholo ba bubble bo bohlokoa.

* Fluidization:

E hiriloe libetheng tse nang le metsi bakeng sa lits'ebetso tse fapaneng tsa lik'hemik'hale, tse thusang ho lekanakabo

ea likhase ka lero kapa phofshoana.

* Tšireletso ea Sensor:

E sireletsa likarolo tse nang le kutloelo-bohloko libakeng tse thata, e thibela tšoaetso

ha e ntse e lumella litšebelisano tse hlokahalang tsa tikoloho.

* Pholiso le Tšehetso ea Catalyst:

E fana ka sethala se setle sa lisebelisoa tsa catalyst, ho tsamaisa

lik'hemik'hale ha li ntse li lumella ho hlaphoheloa habonolo ha li-catalyst tsa bohlokoa.

3. U tseba joang boholo bo loketseng ba pore bakeng sa kopo e itseng?

Ho khetholla boholo bo loketseng ba pore bakeng sa kopo e itseng ho kenyelletsa ho nahana

lintlha tse 'maloa, ho kenyelletsa le mofuta oa maro kapa likhase tse ntseng li sebetsoa, mefuta ea

likaroloana kapa litšila tse lokelang ho tlosoa, le sekhahla sa phallo e lakatsehang. Bakeng sa lisebelisoa tsa filtration,

boholo ba pore hangata bo khethoa hore bo be nyane hanyane ho feta karolo e nyane haholo e hlokang

ho tlhotloa. Lits'ebetsong tse amanang le phallo ea khase kapa sparging, boholo ba pore bo ama

boholo ba li-bubble tse hlahisoang, tse ka amang haholo ts'ebetso ea ts'ebetso.

Ho buisana le baetsi ba maqephe a tšepe a porous joalo ka HENGKO ho ka fana ka lintlha tse thehiloeng ho

boiphihlelo bo pharaletseng le boitseanape ba tekheniki, ho netefatsa khetho ea boholo bo nepahetseng ba pore

bakeng sa kopo efe kapa efe e fanoeng.

4. Ke melemo efe eo lishiti tsa sintered tse sa hloekang li fanang ka tsona ho feta lisebelisoa tse ling?

Lipampiri tsa tšepe tse sa hloekang tsa Sintered li fana ka melemo e mengata ho feta lisebelisoa tse ling, ho li etsa a

khetho e khethiloeng bakeng sa lits'ebetso tse ngata tsa indasteri:

*Tsamaiso:

Matla a bona a phahameng le ho hanyetsa ho senya le ho senya ho netefatsa bophelo bo bolelele ba tšebeletso tlas'a maemo a thata.

* Corrosion Resistance:

Tšireletso ea tlhaho ea tšepe e sa hloekang e loketse ho sebelisoa libakeng tse thata tsa lik'hemik'hale kapa

moo ho pepesetsoang lintho tse senyang ho atileng.

*Botsitso ba Mocheso o Phahameng:

Li khona ho mamella mocheso o phahameng ntle le ho nyenyefatsa, ho etsa hore li tšoanelehe ho sebelisoa li-exchangers tsa mocheso;

li-filters tsa mocheso o phahameng, le lisebelisoa tse ling tse hlokang botsitso ba mocheso.

* Tšebelisano ea Lik'hemik'hale:

Tšepe e sa hloekang e lumellana le mefuta e mengata ea lik'hemik'hale, e fokotsa kotsi ea ho senyeha ha thepa

le tshilafatso.

* Bohloeki le Sterilizability:

Libaka tsa tsona tse boreleli, tse se nang masoba li ka hloekisoa habonolo le ho hloekisoa, ho bohlokoa haholo meriana.

le likopo tsa lijo le lino.

5. Na lishiti tse entsoeng ka tšepe tse sa hloekang li ka etsoa bakeng sa lisebelisoa tse ikhethang?

E, lishiti tsa tšepe tse sa hloekang li ka etsoa ka mokhoa o pharaletseng ho fihlela litlhoko tse ikhethang tsa kopo.

Ho itloaetsa ho ka kenyelletsa mefuta e fapaneng ea boholo ba pore, botenya, boholo ba lakane le sebopeho, hammoho le ho kenyelletsoa

ea likarolo tse itseng tsa alloying ho matlafatsa thepa e itseng joalo ka conductivity kapa ho hanyetsa mocheso.

Baetsi ba kang HENGKO ba sebetsa ka thata ho sebetsa haufi-ufi le bareki ho rala le ho hlahisa tšepe e entsoeng ka bespoke.

litharollo tse lumellanang hantle le lintlha le litekanyetso tsa ts'ebetso tse hlokahalang bakeng sa likopo tsa bona.

Boemo bona ba ho itlhophisa bo netefatsa hore sehlahisoa sa ho qetela se ka sebetsa hantle sebakeng sa sona se reriloeng,

hore na e kenyelletsa litlhoko tse ikhethang tsa ho sefa, ts'ebetso e khethehileng ea lik'hemik'hale, kapa ts'ebeliso efe kapa efe e ikhethileng indastering.

Ikopanye le HENGKO

U itokiselitse ho phahamisa ts'ebeliso ea hau ea indasteri ka litharollo tsa tšepe tse betliloeng?

Ikopanye le rona hoka@hengko.commme ha re fetoleng diphephetso tsa lona katleho.