-

10Pcs/Lot HD Flat e kentsoeng le e silafalitsoeng ka tšepe e nang le porous bronze muffler silencer M5 1/8"...

HD Exhaust Muffler Bronze Model G 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' *Lintlha tse lethathamong lena ke tsa litšupiso feela Pneumatic Sintered Muff...

Sheba lintlha -

Sintered Bronze Muffler 40 Micron Pressure Relief Valve e sa keneleng Metsi

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

Pneumatic exhaust muffler silencer taolo ea phallo ea moea e khutsufalitsoeng ka sekotjana se sehiloeng 1/8 ...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse nang le porous tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HBSL-SEB Sintered Bronze Exhaust Filter Silencer 1/2 Male NPT Thread Pneumatic Mu...

HBSL-SEB Muffler Silencer Model M5 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' 1 1/4'' 1 1/2'' 2'' Lisebelisoa tsa Pneumatic Sintered Mufflers li sebelisa...

Sheba lintlha -

HENGKO Affordable porous powder metal sintered ax100 air pneumatic muffler

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse nang le porous tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HB Micron Stainless steel Bronze Sintered Filter Element 1/4" Air Pneumatic Flow S...

HD Exhaust Muffler Bronze Model 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' Pneumatic Sintered Mufflers Filters utitlize porous sintered bronze filte...

Sheba lintlha -

Maqhubu a phefumolohang a nang le khoele ea banna, tšepe ea koporo ea koporo SS 316 ASP-1/2/3/4/6/8 BV

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa sesebelisoa sa sefa sa boronse se sirelelitsoeng se sirelelitsoeng ho lipeipi tse tloaelehileng. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HBSL-MA V sintered brass pneumatic flat silencer muffler air exhaust lerata le fokotsang le...

Muffler Silencer Model G M5 1/8'' 1/4'' 3/8'' 1...

Sheba lintlha -

Brass air eliminator pneumatic muffler breather vent e nang le 1/8” 1/4” 3/8R...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HENGKO Sintered Porous Metal Pneumatic components/ muffler return valve filthara e...

Sefe ea Moetso oa Boronse oa Valve ea Oli M5 M5 M5 1/8'' 1/4'' Lisefe tsa Pneumatic Sintered Mufflers li sebelisa filthara ea boronse e porous...

Sheba lintlha -

Lisebelisoa tsa ECMO System Breathing bakeng sa lisebelisoa tsa "artificial lung" tsa ECMO

ECMO, kapa extracorporeal membrane pulmonary oxygenation, ke mokhoa o ts'ehetsang bophelo o sebelisang sesebelisoa se ikhethileng sa maiketsetso ho ntša mali ho tsoa pelong, ntle le ...

Sheba lintlha -

HSC Pneumatic Sintered Stainless Stainless Steel Brass Exhaust Muffler Silencer Fitting Noise Fil...

HD Exhaust Muffler Bronze Model 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' 1-1/4'' Pneumatic Sintered Mufflers Filters utilize porous si...

Sheba lintlha -

3 70 micron sintered micropore porous metal bronze copper exhaust muffler filter parts

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

Taolo ea phallo ea mohatsela oa lisilencer tsa tšepe tse porous tse entsoeng ka tšepe e sa hloekang moea...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

Microns Pneumatic Plus Sintered Metal Bronze Breather Vent - 'Mele oa Brass 1/4 ″...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HBSL-SSDM Male Breather Vent Flat Sintered Mesh Pneumatic Air Silencer Mufflers Solenoi...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa sesebelisoa sa sefa sa boronse se sirelelitsoeng se sirelelitsoeng ho lipeipi tse tloaelehileng. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

sintered porous metal powder bronze exhaust filter filthara e loketseng lerata e fokotsang...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa sesebelisoa sa sefa sa boronse se sirelelitsoeng se sirelelitsoeng ho lipeipi tse tloaelehileng. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha -

HSP sintered stainless steel 304/316L porous filter media bakeng sa tshireletso ya Tikoloho,...

Li-Filters tsa Pneumatic Sintered Mufflers li sebelisa li-filters tsa bronze tse sintered tse sirelelitsoeng ho li-fittings tse tloaelehileng tsa liphaephe. Li-mufflers tsena tse kopaneng le tse theko e tlase ...

Sheba lintlha

Likarolo tse ka Sehloohong tsa Sintered Metal Filter

Li-filters tsa tšepe tsa Sintered li na le likarolo tse 'maloa tsa bohlokoa, ho kenyelletsa:

1. Ts'ebetso e phahameng ea ho sefa:

Sintered metal filter e na le boholo bo bonyenyane ba pore le sebaka se seholo sa bokaholimo, se ka tlosang litšila ka har'a likhase le lino tse fapaneng.

2. Tšebelisano e pharaletseng ea lik'hemik'hale:

Li-filters tsena li entsoe ka thepa e nang le khanyetso e phahameng ea lik'hemik'hale, e leng se etsang hore e be tse loketseng mecha e mengata e senyang.

3. Ho hanyetsa mocheso o phahameng:

Li-filters tsa tšepe tse sirelelitsoeng li na le botsitso bo botle ba mocheso, li li lumella ho sebetsa hantle ha mocheso o le holimo.

4. Ho tšoarella:

Li-filters tsena li tšoarella nako e telele, li na le matla a phahameng a mochine le ho hanyetsa ho khoholeha, khoholeho le tšusumetso.

5. Reusability:

Ho fapana le lifilthara tse lahloang, lihloela tsa tšepe tse sirelelitsoeng li ka hloekisoa le ho sebelisoa hape hangata, e leng se etsang hore e be tharollo e bolokang chelete e ngata lits'ebetsong tsa ho sefa.

Tšebeliso ea Sefe e khethehileng ea Sintered Metal

Haele hantle, Li-filters tse Khethehileng li lula li sebelisoa bakeng sa ts'ebeliso e tloaelehileng, ke ts'ebeliso e 'ngoe feela e tla sebelisoa

ka Mocheso o Phahameng o khethehileng haholo,Khatello e Phahameng, HolimoTlhahiso e senyang le

Libaka tsa liteko. Hape ba Bang ba Hloka Sebopeho se Khethehileng sa Moralo, Kahoo U ka Iteanya

HENGKO ho Rarolla Litlhoko tsa Hao tsa OEM Metal Filter.

1. Filtration ea Mokelikeli

2. Fluidizing

4. Phapang

6. Tlhophiso ea Khase

7. Lijo le Seno

Li-filters tsa tšepe tse sintered li na le mekhoa e mengata 'me li ka sebelisoa mefuteng e mengata ea lits'ebetso.

Tse ling tsa lisebelisoa tse tloaelehileng tsa li-filters tsa tšepe tse sintered ke:

1. Sefe ea Mekelikeli:

Li-filters tsa tšepe tse sirelelitsoeng li sebelisoa haholo ha ho sefa lino tse kang metsi, lik'hemik'hale le lihlapolli.

Li-filters tsena li khona ho tlosa lintho tse itseng, litšila le litšila tse tsoang mokelikeling,

li loketse ho sebelisoa indastering ea meriana, ea lijo le ea lino, le ea lik'hemik'hale.

Li boetse li sebelisoa libakeng tsa ho hloekisa metsi a litšila ho tlosa litšila le litšila metsing.

2. Sefe ea Likhase:

Li-filters tsa tšepe tse sirelelitsoeng li boetse li sebelisoa ha ho tlhotloa likhase tse kang moea, khase ea tlhaho le likhase tse ling tsa indasteri.

Li ka tlosa lintho tse itseng, oli le litšila tse ling likhase, e leng se etsang hore li tšoanelehe ho sebelisoa

litlhophiso tsa indasteri le tsa khoebo joalo ka liphaephe tsa khase le litsamaiso tsa moea tse hatelitsoeng.

3. Liphetoho tsa Catalytic:

Li-filters tsa tšepe tse sirelelitsoeng li sebelisoa ho li-converter tsa catalytic ho tlosa litšila tse kotsi likhase tsa koloi.

Ba ka ts'oara le ho sefa ntho e itseng, ha ba ntse ba lumella karabelo ea lik'hemik'hale e hlahang ho catalytic.

converters ho etsahala. Sena se thusa ho fokotsa mesi e tsoang likoloing le ho ntlafatsa boleng ba moea.

4. Fluidization:

Li-filters tsa tšepe tse sintered li sebelisoa ts'ebetsong ea fluidization, moo li sebelisetsoang ho aba khase kapa metsi ka betheng ea

likaroloana tse tiileng. The porous sebopeho sa sintered tšepe filters lumella esita le kabo ea maro, e leng bohlokoa bakeng sa

mekhoa e sebetsang hantle ea fluidization.

5. Tlhophiso ea Oli:

Li-filters tsa tšepe tse sintered li sebelisoa lits'ebetsong tsa ho hloekisa oli ho tlosa litšila, litšila le likaroloana.

lintho tse tsoang ho oli ea enjine, oli ea hydraulic, le oli e meng ea indasteri. Lisefe tsena li khona ho mamella mocheso o phahameng

le likhatello, tse etsang hore e be tse loketseng ho sebelisoa lits'ebetsong tsa indasteri.

6. Lisebelisoa tsa Bongaka:

Li-filters tsa tšepe tse sirelelitsoeng li sebelisoa lisebelisoa tsa bongaka tse kang li-nebulizer le mekhoa ea ho tsamaisa lithethefatsi. Tsena

li-filters li khona ho sefa libaktheria, livaerase le litšila tse ling ho tsoa merianeng le likhase tsa bongaka,

e thusa ho netefatsa polokeho ea mokuli.

7. Sepakapaka le Tšireletso:

Lisebelisoa tsa tšepe tse sirelelitsoeng li sebelisoa indastering ea lifofane le ea ts'ireletso bakeng sa lits'ebetso tse fapaneng,

ho kenyelletsa ho tlhotla mafura, ho tlhotla ha hydraulic fluid, le moea le khase. Li-filters tsena li tlameha ho kopana le ts'ebetso e tiileng le polokeho

litekanyetso, e leng se etsang hore li-filters tsa tšepe tsa sintered e be khetho e nepahetseng bakeng sa liindasteri tsena.

Tšehetso ea Litharollo tsa Moenjiniere

Ho theosa le lilemo, HENGKO e rarollotse litlhoko tse rarahaneng haholo tsa ho sefa le ho laola phallo ka bophara

liindasteri tse ngata lefatšeng ka bophara.Ho rarolla boenjiniere bo rarahaneng bo lumellanang le kopo ea hau ke sepheo sa rona le

Hape ke sepheo sa rona se tloaelehileng ho boloka lisebelisoa le merero ea hau e sebetsa hantle le ka mokhoa o tsitsitseng joalokaha ho reriloe , Kahoo

Hobaneng re sa sebetse ka matsoho ho phethela merero ena hammoho le ho hlola mathata, ho nts'etsapele

li-filters tse khethehileng tsa merero ea hau e khethehileng kajeno.

Rea u amohela ho Arolelana Morero oa Hau le ho Sebetsa le HENGKO, Re Tla Fana ka Sesefo se Khethehileng sa Metal se Molemohali

Tharollo Bakeng sa Merero ea Hao.

Tataiso ea Mehato ka Mehato bakeng sa Iketsetse Sintered Metal Filter

Feme ea hau e ntle ka ho fetesisa e ikhethileng bakeng sa merero ea hau e khethehileng ea litlhoko tse phahameng, haeba u sa khone ho e fumana kapa e tšoanang

Sefa lihlahisoa, Rea u amohelaho ikopanya le HENGKO ho sebetsa 'moho ho fumana tharollo e molemo ka ho fetisisa,' me mokhoa oa ho

Li-filters tse khethehileng tsa OEM,Ka kopo E hlahlobe leIteanye le ronabua lintlha tse ling.

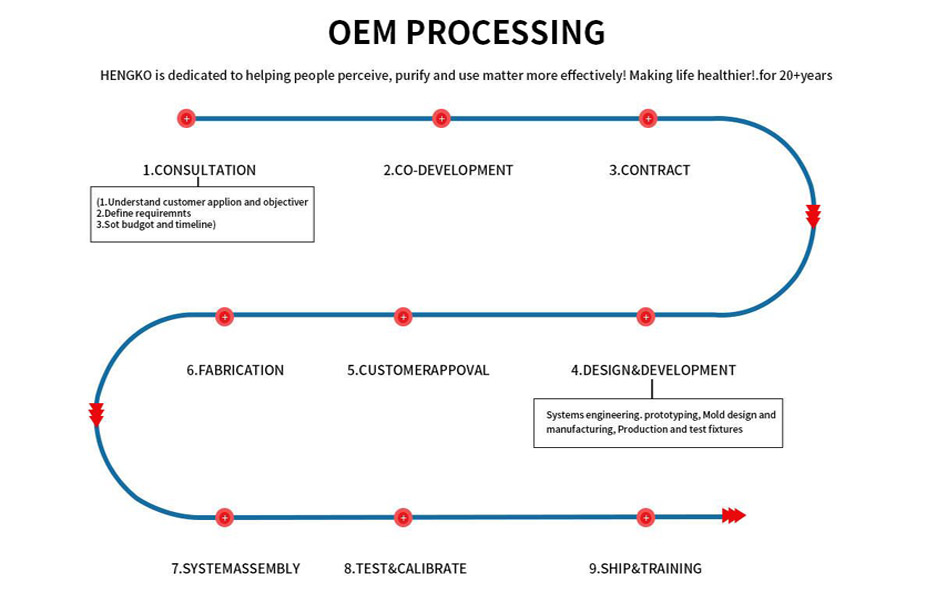

HENGKO e Ikemiseditse ho Thusa Batho ho Lemoha, ho Hloekisa le ho Sebelisa Taba ka Katleho Haholoanyane! Ho etsa hore bophelo bo be bobebe ho feta lilemo tse 20.

1.Therisano le Ikopanye le HENGKO

2.Tšebelisano-'moho

3.Etsa Konteraka

4.Moralo le Ntlafatso

5.Kabelo ea bareki

6. Tlhahiso (//)

7. Tsamaiso

8. Lekola & Lekanya

9. Thomello le Koetliso

U ntse u na le Lipotso 'me u rata ho tseba lintlha tse ling bakeng saSefa se khethehileng sa OEM, Ka kopo ikutloe u lokolohile ho Iteanya le Rona Hona joale.

Hape U ka khonaRe romelle ImeileKa ho toba ka tsela e latelang:ka@hengko.com

Re tla khutlisa ka lihora tse 24, re leboha mokuli oa hau!

FAQ ka Sintered Metal Filters :

1. Sefe ea tšepe e sintered ke eng?

A: Asintered metal filterke sefe se entsoeng ka ho sila liphofshoana tsa tšepe hammoho ho etsa aporous material

e dumellang maro kapa digase ho phalla ha e ntse e tjheka makumane kapa ditshila.

2. Melemo ea ho sebelisa li-filters tsa tšepe tse sintered ke life?

Li-filters tsa tšepe tsa Sintered li fana ka motsoako o ikhethang oa thepa e etsang hore e be molemo lits'ebetsong tse fapaneng. Mona ke tse ling tsa melemo ea bohlokoa:

1. Matla le nako e telele:

Ho fapana le lifilthara tsa pampiri kapa tsa masela, lihloela tsa tšepe tse sirelelitsoeng li matla ka mokhoa o makatsang 'me li khona ho mamella likhatello tse phahameng le mocheso. Sena se li etsa hore li tšoanelehe bakeng sa lits'ebetso tse batlang liindasteri tse kang ts'ebetso ea lik'hemik'hale, ho hloekisa petrochemical, le tlhahiso ea matla.

2. Porosity e phahameng le filtration e nepahetseng:

Porosity e laoloang ea li-filters tsa tšepe tse sintered li lumella ho hloekisa ka mokhoa o nepahetseng oa likaroloana ho ea ho tse nyenyane haholo. Sena se finyelloa ka ho laola ka hloko boholo le kabo ea li-pores nakong ea ts'ebetso ea sintering.

3. Corrosion resistance:

Lisefe tse ngata tsa tšepe tse entsoeng ka sintered li entsoe ka tšepe e sa hloekang kapa litšepe tse ling tse sa jeng, tse etsang hore li tšoanelehe ho sebelisoa le lik'hemik'hale tse bohale le maro. Sena se fokotsa tlhoko ea ho nchafatsa le ho lokisoa khafetsa.

4. Ho hloeka le ho sebelisoa hape:

Ho fapana le li-filters tse lahliloeng, li-filters tsa tšepe tse sirelelitsoeng li ka hloekisoa habonolo le ho sebelisoa hape, e leng khetho e bolokang chelete e ngata le e se nang tikoloho ha nako e ntse e ea.

5. Ho hanyetsa mocheso o phahameng oa mocheso:

Lisefe tsa tšepe tse sirelelitsoeng li ka mamella liphetoho tse potlakileng mochesong ntle le ho peperana kapa ho soahlamana, li etsa hore li lokele ho sebelisoa libakeng tse nang le mocheso o phahameng joalo ka li-turbine le lienjine.

6. Ho feto-fetoha ha maemo:

Lisefa tsa tšepe tse sirelelitsoeng li ka etsoa ka mokhoa o ikhethileng ho fihlela litlhoko tse fapaneng ho latela boholo ba pore, sebopeho le thepa. Sena se etsa hore li ikamahanye le lits'ebetso tse fapaneng liindastering tse fapaneng.

Mona ke melemo e meng eo u lokelang ho e bua:

* Mohaho o nang le li-welded tsohle:

Lisefe tsa tšepe tse sirelelitsoeng li na le sebopeho se se nang sekoli, se tlosang kotsi ea ho lutla ho amanang le lisefe tse khomaretsoeng kapa tse rokiloeng.

* Bophelo bo bolelele ba tšebeletso:

Ka lebaka la ho tšoarella le ho hloeka ha tsona, lihloela tsa tšepe tse sirelelitsoeng li na le nako e telele ea bophelo ha li bapisoa le mefuta e meng ea lihloela.

* Biocompatibility:

Litšepe tse ling tse entsoeng ka sintered joalo ka titanium lia lumellana, li etsa hore li tšoanelehe bakeng sa lits'ebetso tsa bongaka le tsa meriana.

Ka kakaretso, melemo ea ho sebelisa li-filters tsa tšepe tse sirelelitsoeng li li etsa khetho e matla bakeng sa lits'ebetso tse boima moo ts'ebetso e phahameng, e tšoarellang, le ts'ebeliso e ncha e leng bohlokoa.

3. Ke likopo tse ling tse tloaelehileng tsa li-filters tsa tšepe tse sintered?

A: Li-filters tsa tšepe tse sirelelitsoeng li sebelisoa liindastering tse fapaneng ho kenyelletsa lijo le lino,

meriana, lik'hemik'hale, petrochemical, phekolo ea metsi le likoloi.

Hangata li sebelisoa ho sefa metsi kapa likhase tse kang oli, mafura, khase kapa metsi.

4. Ke eng e lokelang ho lefshoa ha u khetha moetsi oa sintered metal filter?

A: Ha u khetha moetsi oa sintered metal filter, batla k'hamphani e nang le boiphihlelo le boiphihlelo ho eona

ho hlahisa li-filters tsa boleng bo holimo, ho sebelisa mekhoa e tsoetseng pele ea tlhahiso le theknoloji, ho fana ka mokhoa oa ho itloaetsa

dikgetho le tšehetso ea botekgeniki, 'me e na le botumo ba litšebeletso tsa bareki le phano Khampani e nang le botumo bo botle.

5. Li-filters tsa tšepe tse sintered li etsoa joang?

Li-filters tsa tšepe tse entsoeng ka sintered li entsoe ka mokhoa o tsotehang o kenyelletsang ho fetola phofo ea tšepe hore e be mohaho o matla, o nang le masoba. Mona ke karohano ea mohato ka mohato:

1. Ho lokisa phofo ea tšepe:

Leeto le qala ka lisebelisoa tsa tšepe, tse atisang ho etsoa ka tšepe e sa hloekang, boronse, nickel, kapa titanium. Li-powders tsena li ka fumanoa ka mekhoa e fapaneng e kang ho sila, atomization, kapa esita le ho bola ha lik'hemik'hale.

2. Ho kopanya le ho bopa:

Phofo ea tšepe e kopantsoe le li-binders le lubricant ho ntlafatsa phallo ea eona le litšobotsi tsa ho hatella. Motsoako ona e ka nako eo petelitsoe ka sebopeho se lakatsehang ea filthara element ho sebelisa khatello e phahameng shoa. Libopeho e ka ba li-discs tse bonolo, li-tubes tse rarahaneng, kapa li-geometri tse rarahaneng ho latela ts'ebeliso.

3. Sintering:

Ena ke pelo ea ts'ebetso moo boselamose bo etsahalang. Libopeho tse hatelitsoeng li futhumatsoa sebakeng se laoloang mocheso o ka tlaase ho ntlha ea ho qhibiliha ea tšepe. Mocheso ona o etsa hore likaroloana tsa tšepe li kopane hammoho libakeng tsa tsona tsa ho kopana, ho theha marang-rang a matla, a hokahaneng ha a ntse a siea sebaka se lekaneng sa sekheo bakeng sa porosity ea sefe.

4. Ho qeta le ho hloekisa:

Hang ha e se e siiloe, karolo ea sefa e kena tšebetsong e eketsehileng joalo ka ho pholisa, ho koala (ho tlosoa ha lintho tse tlamang), le ho qeta bokaholimo. Li-filters tse ling li ka hloka mochini o eketsehileng kapa kopano ho fihlela sebopeho sa ho qetela se lakatsehang.

5. Taolo ea boleng le liteko:

Mokhahlelo oa ho qetela o kenyelletsa licheke tse matla tsa taolo ea boleng ho netefatsa hore filthara e kopana le lintlha tse hlokahalang bakeng sa porosity, kabo ea boholo ba pore, matla le liparamente tse ling. Hangata sena se kenyelletsa tlhahlobo ea pono, litekanyo tsa boholo, esita le tlhahlobo ea ts'ebetso ka maro.

Mme voila! Phofo e bonolo ea tšepe e fetoloa ntho e matla, e ka sebelisoang hape e loketseng ho sebetsana le mesebetsi e fapaneng ea ho sefa liindasteri.

Ke habohlokoa ho hlokomela hore ho na le mefuta e fapaneng ea ts'ebetso e nepahetseng ho itšetlehile ka mofuta oa tšepe, thepa e lakatsehang, le moetsi ea khethehileng. Mekhoa e meng e kenyelletsa ho sebelisa likhoele tsa tšepe tse entsoeng esale pele sebakeng sa phofo, kapa ho sebelisa mekhoa e fapaneng ea ho futhumatsa joalo ka microwave sintering.

Ka bokhuts'oane, ts'ebetso ea sintering e theha sebopeho sa tšepe se matla empa se na le masoba se sefang maro hantle ha se ntse se boloka thepa e lakatsehang joalo ka mocheso o phahameng le khatello ea khatello. Sena se etsa hore li-filters tsa tšepe tse sirelelitsoeng e be sesebelisoa sa bohlokoa likarolong tse fapaneng, ho tloha ho lisebelisoa tsa bongaka ho ea ho boenjiniere ba likoloi.

6. Ke lisebelisoa life tse tloaelehileng tse sebelisoang ho etsa li-filters tsa tšepe tse sintered?

A: Li-filters tsa tšepe tse entsoeng ka sintered li ka etsoa ka lisebelisoa tse fapaneng tse kenyelletsang tšepe e sa hloekang, boronse, nickel, titanium.

le li-alloys tse ling. Khetho ea thepa e itšetlehile ka ts'ebeliso e khethehileng le thepa e lakatsehang ea filthara.

7. Na sefahla sa tšepe sa sintered se ka etsoa ka mokhoa o ikhethileng?

A: E, li-filters tsa tšepe tse sirelelitsoeng li ka etsoa ho finyella litlhoko tse khethehileng tsa lisebelisoa tse fapaneng. Baetsi

e ka fetola boholo ba pore, botenya, sebopeho le likarolo tse ling ho ntlafatsa ts'ebetso ea filtration.

8. Ke hloekisa le ho boloka lifeela tsa tšepe tse sintered joang?

A: Li-filters tsa tšepe tse entsoeng ka sintered li ka hloekisoa ka ho hlatsuoa ka metsi kapa moea o hatelitsoeng kapa ka ho qoelisoa ka metsing.

tharollo ea ho hloekisa. Ho bohlokoa ho latela likhothaletso tsa ho hloekisa le tlhokomelo ea moetsi ho

etsa bonnete ba ts'ebetso e nepahetseng ea filthara le bophelo ba ts'ebeletso.