-

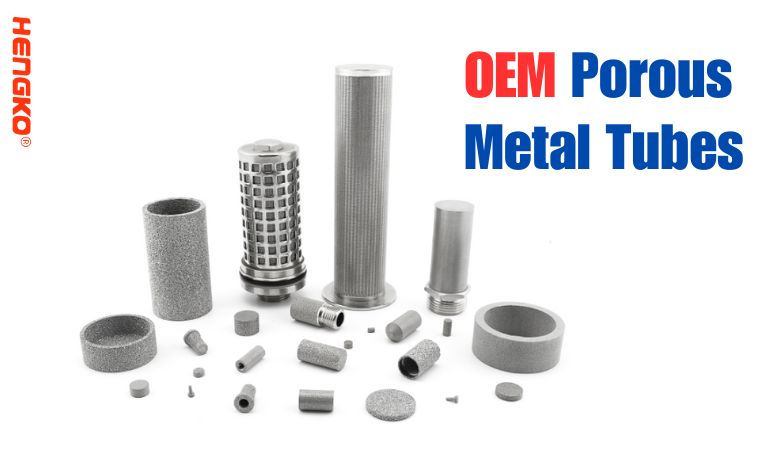

Stainless Steel Sintered Porous Metal Filter Tubes Porosity Ho theohela ho 0.2 µm - Ho F...

Pore boholo: 0.2-100microns Materials: SS Metal Porosity:30% ~ 45% Working Pressure:3MPa Operating Mocheso:600℃ Likopo tsa sintered porous metal ...

Sheba lintlha -

Malebela a Phetolelo a Micro-Bubble a Porous Sparger bakeng sa Fermentation / Bioreactor Air Aeration...

Melemo ea HENGKO Porous Metal Micro Spargers Ka lebaka la ho qhibiliha ho tlase ha oksijene mecheng e mengata ea setso sa lisele, ho ntlafatsa limatlafatsi tsena tse bohlokoa ho ka ba ...

Sheba lintlha -

Stainless Steel Tubeless Tyre Valve E Matla 'me e Tšoarehile Tire Valve e Khutšoane Bakeng sa Truru ea Koloi...

Tlhaloso ea Lihlahisoa Valve ke sesebelisoa sa 'mele se ikemetseng se lumellang khase ho kena sebakeng sa thaere e se nang tube kapa tube ha e buloa, ebe ...

Sheba lintlha -

Sefa sa Wholesale Wire Mesh Stainless Steel 10 Micron Sintered Tube For Pharmaceutical M...

Li-filters tsa tšepe tse sa hloekang li loketse ho sebelisoa ha ho hlokahala lintlha tsa boenjiniere tse hlokang ho sefa maemong a mabe a tikoloho, joalo ka jet en...

Sheba lintlha -

Sintered Porous Metal Stainless Steel Filter Tube bakeng sa Fiber Optic Collimator HENGKO

Sehlahisoa Hlalosa li-cartridges tsa tšepe tse porous li ka etsoa bakeng sa mefuta e mengata ea lisebelisoa le litlhaloso 'me li ka kopanngoa le tšepe le e seng meta ...

Sheba lintlha -

Ho nepahala ho Hoholo Tšebeliso e Tlase ea I2C Interface Temperature & Mongobo o amanang le Sensor...

Mocheso oa HENGKO le sensor ea mongobo e entsoeng ka sekhahla sa ts'ireletso sa IP66 se nang le tšepe e matla e phahameng ea tšepe e sa jeleng paate, e ka sebelisoa ka kotloloho...

Sheba lintlha -

probe ea sensor ea mocheso le mongobo o amanang le tšepe e atolositsoeng ea tšepe e sa hloekang le ...

HT-E067 e tsamaisanang le mongobo / mocheso oa mocheso o fana ka mokhoa o ts'epahalang le o theko e tlase bakeng sa lits'ebetso tsa tlhahlobo ea duct mount.Li-sensor tsa boemo bo tiileng li sebetsa ...

Sheba lintlha -

Sintered Sparger Tube e nang le Porous Metal Stainless Steel Tank le In-line Spargers e Sebelisitsoeng ...

Re hlahisa HENGKO sintered spagers, tharollo ea mantlha ea ho hlahisa likhase ka har'a maro.Sehlahisoa sena se iqapetsoeng se sebelisa likete tsa...

Sheba lintlha -

Ts'ebetso e phahameng ea porous sintered metal stainless steel isostatic filters tubes tšehetso ...

Li-tubes tse entsoeng ka tšepe tse sa hloekang li entsoe ka phofo ea tšepe e sa hloekang, e sebelisoang ke theknoloji ea sintering.Sehlahisoa sena se ka hloekisa mecha ea litaba e silafetseng le ho ...

Sheba lintlha -

Mochini o nang le hydrogen e ngata ea metsi - sintered SS 316L tšepe e sa hloekang 0.5 2 micron moea o ...

Metsi a haedrojene a hloekile, a matla ebile a na le hydron.E thusa ho hloekisa mali le ho etsa hore mali a tsamaee.E ka thibela mefuta e mengata ea mafu le ho ntlafatsa batho ...

Sheba lintlha -

E kentsoe ka ho toba Porous Metal In-Line Sparger Tube Hlahisa Li-bubble tse Nyenyane

HENGKO sintered spagers e kenya likhase ka har'a maro ka likete tsa masoba a manyane, a etsa lipulumo tse nyane haholo hape li le ngata ho feta ka liphaephe tse chekiloeng ...

Sheba lintlha -

316L tšepe e se nang porous tšepe e otlolohileng filthara e bōpehileng joaloka sparging likopano

Li-diffuser tsa majoe a sintered li sebelisoa hangata bakeng sa ho enta ka porous gase.Li na le boholo bo fapaneng ba pore (0.5um ho 100um) e lumellang lipululana tse nyane ho phalla ...

Sheba lintlha -

316L tšepe e sa hloekang porous sparger tube sintered ntlha bakeng sa lisebelisoa tsa sekepe sa belisoa

E khomaretse ntlha ea tšupu ea sparger, ntlha ena ea tšepe e sa hloekang ea 316L e fumaneha ka mefuta e fapaneng ea boholo ba pore.The 5 10 15 50 100 pore frit ke ...

Sheba lintlha -

Cylindrical 25 50 micron tšepe e sa jeleng li-micron porous sintered filter tube bakeng sa...

Li-tubes tsa filthara ea tšepe ea HENGKO li entsoe ka lisebelisoa tsa phofo tse 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng.Ba bile w...

Sheba lintlha -

Porous metal filter tube bakeng sa ho hloekisa tsamaiso ea mocheso le lik'hemik'hale tse khethehileng |HENGKO

Li-tubes tsa filthara ea tšepe ea HENGKO li entsoe ka lisebelisoa tsa phofo tse 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng.Ba bile w...

Sheba lintlha -

Moetsi oa litsebi o hlophisitse tube ea sintered porous metal filter e sebelisetsoang bongaka...

Li-filters tsa HENGKO sintered hangata li sebelisetsoa tlhoekiso le ho sefa metsi le khase, karohano le ho khutlisa likaroloana tse tiileng, pholiso ea phefumoloho ...

Sheba lintlha -

0.2um ho 90 micron 5 - 100mm bophahamo phofo kapa terata letlooeng porous sintered tšepe sta...

Li-tubes tsa filthara ea tšepe ea HENGKO li entsoe ka lisebelisoa tsa phofo tse 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng.Ba bile w...

Sheba lintlha -

Sintered tšepe phofo porous 316l SS stainless steel filtara tube, 2 μm 5 7 10 15 20 30 ...

Li-tubes tsa filthara ea tšepe ea HENGKO li entsoe ka lisebelisoa tsa phofo tse 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng.Ba bile w...

Sheba lintlha -

2 10 20 25 microns porous SS 304/316L tšepe sintered stainless steel filtara tube bakeng sa li...

Li-tubes tsa filthara ea tšepe ea HENGKO li entsoe ka lisebelisoa tsa phofo tse 316L kapa mesh ea tšepe e sa hloekang ea multilayer ka mocheso o phahameng.Ba bile w...

Sheba lintlha -

Sintered metal 316 filthara ea tšepe e sa hloekang ea bongaka bakeng sa mokelikeli le khase ...

Sehlahisoa se hlalosang lintho tse sefang tse nang le porous li 'nile tsa sebelisoa haholo libakeng tsa metallurgical, lik'hemik'hale, tsa meriana, tsa lifofane le tsa lifofane.Porous Metal media...

Sheba lintlha

Ke Hobane'ng ha U Sebelisa Porous Metal Tube?

Ho na le mabaka a 'maloa a bohlokoa a etsang hore li-tubes tsa tšepe tsa porous li sebelisoe lits'ebetsong tse fapaneng:

Sefa:

* Mosebetsi oa tsona o ka sehloohong ke ho sefa.Boholo ba pore bo laoloang ka nepo bo li lumella ho tlosa litšila, likaroloana le litšila tse tsoang marong le likhase.Sena se ka ba bohlokoa liindastering tse kang tsa meriana, ts'ebetso ea lik'hemik'hale, le lijo le lino, moo bohloeki bo leng bohlokoa.

* Bophahamo ba pore bo ka tloha ho submicron ho ea ho limilimithara tse 'maloa, ho li nolofalletsa ho sefa mefuta e mengata ea boholo ba likaroloana.

Phallo e Laolehileng:

* Sebopeho sa porous se lumella ho phalla ho laoloang ha metsi le likhase.

Sena se ka sebelisoa bakeng sa ho tsamaisa moea, kabo ea khase, ho etsa metsi, le lits'ebetso tse ling moo taolo e nepahetseng ea phallo e hlokahalang.

* Phatlalatso ea pore e ts'oanang e tiisa ho phalla ho tsitsitseng ho pholletsa le tube, ho thibela mocha le ho fana ka khatello e sa lekaneng.

Ho tšoarella le Matla:

* E entsoe ka litšepe tse kang tšepe e sa hloekang, nickel, kapa boronse, li-tubes tsa tšepe tse porous li tšoarella nako e telele 'me li khona ho mamella maemo a thata a ts'ebetso, ho kenyelletsa le mocheso o phahameng, likhatello le tikoloho e senyang.

* Sena se etsa hore li tšoanelehe bakeng sa ts'ebeliso ea nako e telele lits'ebetsong tse batloang ke indasteri.

Melemo e meng:

* Li-tubes tsa tšepe tse porous le tsona li bobebe, li hloekisoa habonolo, 'me li ka sebelisoa hape.Li ka etsoa habonolo le ho bōptjoa hore e be mefuta e sa tšoaneng, e leng ho eketsang ho feto-fetoha ha tsona.

Mona ke mehlala e tobileng ea lits'ebetso moo li-tubes tsa tšepe tse porous li sebelisoang:

* Li-diffuser tsa moea:libakeng tsa ho hloekisa metsi a litšila ho kenya oksijene metsing bakeng sa kholo ea baktheria.

* Lifilimi tsa mafura:likoloing le likoloing tse ling ho tlosa litšila mafura.

* Li-implants tsa bongaka:bakeng sa ho kenya masapo le ho fana ka lithethefatsi.

* Litšehetso tsa Catalyst:ka li-reactor tsa lik'hemik'hale ho tšoara le ho aba li-catalysts.

* Li-Silencers:litsamaisong tsa mosi bakeng sa ho fokotsa lerata.

Qetellong, mabaka a tobileng a hore na ke hobane'ng ha motho a ka khetha tube ea tšepe e nang le porous e itšetlehile ka kopo e khethehileng le litlhoko tsa eona.Leha ho le joalo, motsoako oa bona o ikhethang oa ho hloekisa, ho phalla ho laoloang, ho tšoarella, le melemo e meng e etsa hore e be sesebelisoa sa bohlokoa bakeng sa mefuta e mengata ea liindasteri.

Mosebetsi o ka Sehloohong

Thesintered tšepe tubee batla e ts'oana le tse lingli-filters tsa tšepe tse sintered or sintered metal sparger.

Mosebetsi o ka sehloohong oa li-tubes tsa tšepe tsa porous ke ho fana ka mokhoa o sebetsang hantle le o ka tšeptjoang oa ho hloekisa, ho arohana le ho laola

ho phalla ha mokelikeli le khase.

Li-tubes tsena tsa tšepe tse porous li entsoe ka likaroloana tsa tšepe tsa boleng ba 316L SS tse kopantsoeng hammoho ka sintering.

ts'ebetso, ho theha sebopeho se nang le masoba a hokahaneng.Litšobotsi tse ikhethang tsa li-tubes tsa tšepe tse porous

li thusa ho etsa mesebetsi e mengata ea bohlokoa:

1. Sefe:

Sepheo sa mantlha sa li-tubes tsa tšepe tse porous ke ho sebetsa e le li-filters, ho tlosa litšila, likaroloana le litšila tse tsoang mokelikeli le likhase.Taolo e nepahetseng ea boholo ba pore e ba lumella ho fihlella tlhoekiso e ntle ho fihlela maemong a submicron, ho netefatsa bohloeki ba seaplane se sebetsoang.

2. Phatlalatso ea Khase le Mokelikeli:

Li-tubes tsa tšepe tse nang le porousdi sebedisoa ho hasa digase kapa lero ka ho lekana le ka ho tshoana.Ka ho laola boholo ba pore le ho ajoa, ba ka etsa mokhoa o ts'oanang oa phallo, ho thibela mocha le ho ntlafatsa katleho ea ho hasana.

3. Fluidization:

Lits'ebetsong tsa bethe tse nang le metsi, li-tubes tsena li sebelisoa ho ntša likaroloana tse tiileng, ho etsa hore ho be le boemo bo kang ba mokelikeli.Kabo e ts'oanang ea li-pores e thusa ho fihlela metsi a sebetsang hantle le a laoloang.

4. Venting le Pressure Equalization:

Li-tubes tsa tšepe tse nang le porous li sebelisoa bakeng sa ho ntša likhase, ho leka-lekanya khatello, kapa ho imolla maemo a vacuum lits'ebetsong le lisebelisoa tse fapaneng.Li nolofalletsa moea kapa khase ho feta ha li ntse li thibela ho kena ha litšila.

5. Phokotso ea Lerata:

Lits'ebetsong tse ling, li-tubes tsa tšepe tse porous li sebelisoa e le li-silencer kapa li-mufflers ho fokotsa maemo a lerata a hlahisoang ke phallo ea likhase kapa maro.

6. Phatlalatso:

Li-tubes tsa tšepe tse porous li thusa ho tsamaisa khase kapa mokelikeli ka ho lumella limolek'hule hore li fete ka masobeng a tsona a hokahaneng.Thepa ena e fumana ts'ebeliso likarolong tse fapaneng, joalo ka ts'ebetso ea catalysis le phetisetso ea batho ba bangata.

7. Tšehetso le Kabo:

Liindastering tse ling, li-tubes tsa tšepe tse nang le porous li sebetsa e le mehaho ea ts'ehetso bakeng sa li-catalysts kapa lintho tse ling, ho fana ka moralo o tsitsitseng le ho thusa kabong e tšoanang.

Ka lebaka la porosity ea bona e phahameng, ho tšoarella, ho hanyetsa lik'hemik'hale, le mekhoa e laoloang ea pore, li-tubes tsa tšepe tse nang le porous li fumana tšebeliso e ngata liindastering tse kang meriana, petrochemicals, phekolo ea metsi, likoloi, sebaka sa sefofane le tse ling tse ngata, moo ho sebetsang hantle ho hloekisa le ho laola ho phalla ho leng bohlokoa. bakeng sa ts'ebetso e nepahetseng le polokeho.

Molao-motheo oa ho sebetsa oa Sintered Porous Metal Tubes

Molao-motheo oa ts'ebetso oa li-tubes tsa sintered porous metal o thehiloe holim'a thepa e ikhethang ea sebopeho sa tšepe se sirelelitsoeng, se lumellang ho hloekisa hantle le ho laola ho phalla ha metsi le likhase.Mona ke kakaretso ea molao-motheo oa ts'ebetso:

1. Sintering Process:

Li-tubes tsa tšepe tse porous li etsoa ka mokhoa o bitsoang sintering.E kenyelletsa ho kopanya likaroloana tsa tšepe, hangata tšepe e sa hloekang kapa lisebelisoa tse ling tsa tšepe, hore e be sebopeho se ikhethileng, joalo ka tšupu.Likaroloana tsa tšepe li futhumatsoa mochesong o ka tlaasenyana ho moo ho qhibilihang, ho etsa hore li kopane, ho etsa marang-rang a tiileng le a hokahaneng a masoba.

2. Sebopeho sa Pore:

Li-tubes tsa sintered tsa tšepe li na le sebopeho sa pore se hlalositsoeng ka lebaka la ho hlophisoa ha likaroloana tsa tšepe nakong ea ts'ebetso ea sintering.Boholo, sebopeho le kabo ea li-pores tsena li ka laoloa ka nepo nakong ea tlhahiso ho fihlela litlhoko tse khethehileng tsa ho sefa.

3. Sefa:

Mosebetsi o ka sehloohong oa li-tubes tsa tšepe tse sintered ke ho hloekisa.Ha mokelikeli kapa khase e feta ka har'a tube, litšila, likaroloana le litšila li kenngoa ka har'a li-pores.Boholo ba pore bo etselitsoe ho lumella mokelikeli kapa khase e lakatsehang hore e fete ha e ntse e thibela lintho tse sa batleheng.

4. Bokhoni ba ho Sefa:

Bokhoni ba ho sefa ha li-tubes tsa tšepe tse sintered li itšetlehile ka boholo ba pore le sebaka sohle se teng bakeng sa ho sefa.Lipore tse nyane li ka tšoara likaroloana tse nyane, tse fanang ka ts'ebetso e phahameng ea ho sefa.

5. Taolo ea Phallo:

Sebopeho sa pore se hokahaneng sa li-tubes tsa tšepe tse sintered se nolofalletsa taolo e nepahetseng holim'a phallo ea mokelikeli kapa khase.Boholo le kabo ea li-pores li susumetsa lebelo la phallo le ho theoha ha khatello ho pholletsa le tube.Thepa ena e bohlokoa lits'ebetsong moo ho hlokehang kabo ea phallo e ts'oanang kapa ho laoloa ke metsi.

6. Ho tšoarella le ho hanyetsa:

Li-tubes tsa tšepe tse sintered li tšoarella ka nako e telele 'me li hanana le khatello ea kelello ea mochine, lik'hemik'hale le mocheso o phahameng.Mokhoa oa sintering o tiisa hore likaroloana tsa tšepe li tlamahane ka thata, li fana ka botšepehi ba sebopeho esita le tlas'a maemo a thata a ho sebetsa.

7. Ts'ebeliso hape le Bohloeki:

Sintered porous metal tubes e ka hloekisoa habonolo le ho sebelisoa hape.Li ka mamella mekhoa e fapaneng ea ho hloekisa, joalo ka ho hlatsoa mokokotlo, ho hloekisa ka ultrasonic, kapa ho hloekisa lik'hemik'hale, ntle le ho senya ts'ebetso ea tsona ea ho hloekisa.

Molao-motheo o sebetsang oa li-tubes tsa tšepe tse sintered o li etsa hore li feto-fetohe haholo 'me li loketse mefuta e mengata ea likopo liindastering tse kang petrochemicals, meriana, phekolo ea metsi, sefofane, le tse ling.Li khethiloe bakeng sa ho sefa ha tsona hantle, ho tšoarella, le bokhoni ba ho mamella maemo a thata, ho fana ka ts'ebetso e tšepahalang lits'ebetsong le lits'ebetsong tsa bohlokoa.

Seo U Lokelang ho se Hlokomela Ha Li-Tubes tsa Metal tse khethehileng tsa OEM bakeng sa merero ea hau ea ho sefa?

Ha u nahana ka li-tubes tse khethehileng tsa tšepe tsa OEM bakeng sa sistimi kapa merero ea hau ea ho sefa, ho na le lintlha tse 'maloa tsa bohlokoa tse lokelang ho nahanoa ho netefatsa ts'ebetso e nepahetseng le ts'ebetsong e atlehileng.Mona ke lintlha tse ling tsa bohlokoa:

1. Litlhoko tsa ho Sefa:

Hlalosa ka ho hlaka litlhoko tse khethehileng tsa ho sefa bakeng sa kopo ea hau.Etsa qeto ea bokhoni bo lakatsehang ba ho sefa, boholo ba pore, le sekhahla sa phallo se hlokahalang ho fihlela sephetho se lakatsehang.

2. Litšobotsi tsa Mokelikeli kapa Khase:

Utloisisa litšobotsi tsa mokelikeli kapa khase e lokelang ho sefshoa, ho kenyelletsa mocheso, khatello, viscosity le ho lumellana ha lik'hemik'hale.Etsa bonnete ba hore thepa e khethiloeng ea tšepe e nang le porous e ka mamella maemo a sebetsang a reretsoeng.

3. Boholo ba Pore le Sebopeho:

Sebetsa le moetsi oa OEM ho hlophisa boholo ba pore le sebopeho sa li-tubes tsa tšepe tse porous ho tsamaisana le litlhoko tsa kopo ea hau.Nahana ka boholo ba likaroloana tsa litšila tse lokelang ho tlosoa le litšobotsi tse lakatsehang tsa phallo.

4. Khetho ea Lintho:

Khetha thepa e nepahetseng ea tšepe e ipapisitseng le khanyetso ea eona ea lik'hemik'hale, thepa ea mochini, le ho tsamaellana le mochini o tlhotliloeng.Lisebelisoa tse tloaelehileng li kenyelletsa tšepe e sa hloekang, boronse, nickel le titanium.

5. Moralo le Geometry:

Sebelisana 'moho le moetsi oa OEM ho rala sebopeho le boholo ba tšupu hore e lekane sistimi kapa projeke ea hau.Nahana ka lintlha tse kang bolelele, bophara, le likhokahano tsa ho qetela bakeng sa ho kopanya habonolo.

6. Bokhoni ba ho Filtration le ho theoha ha Khatello:

Leka-lekanya ts'ebetso ea ho sefa le ho theoha ha khatello ho pholletsa le li-tubes tsa tšepe tse porous.Ts'ebetso e phahameng ea ho sefa e ka lebisa ho theoheng ha khatello, e ka amang ts'ebetso ea sistimi.

7. Bohloeki le Tlhokomelo:

Buisanang ka litlhoko tsa bohloeki le tlhokomelo ea li-tubes tsa tšepe tse porous.Netefatsa hore li ka hloekisoa habonolo le ho sebelisoa hape ho ntlafatsa nako ea bophelo le ho fokotsa nako.

8. Ho Itloaetsa le Boitsebelo:

Sebetsa le moetsi ea nang le boiphihlelo oa OEM ea nang le rekoto e netefalitsoeng ea ho hlahisa li-tubes tse khethehileng tsa tšepe.Ba lokela ho ba le boiphihlelo ba ho etsa li-tubes ho latela litlhoko tsa hau tse ikhethang.

Ka ho nahana ka lintlha tsena ka hloko le ho sebelisana haufi-ufi le moetsi oa OEM, u ka etsa bonnete ba hore li-tubes tsa tšepe tse khethehileng tsa OEM li entsoe le ho lokisoa ho kopana le sistimi ea hau ea ho sefa kapa litlhoko tse ikhethang tsa morero, 'me qetellong li lebisa ntlafatsong ea ts'ebetso, ts'epahalo le ts'ebetso.

LBH

1. Likarolo tsa bohlokoa tsa li-tubes tsa tšepe tse porous sintered ke life?

Li-tubes tsa tšepe tse nang le porous sintered li fana ka likarolo tse 'maloa tsa bohlokoa tse li etsang hore e be tse ikhethang le tse molemo haholo bakeng sa lits'ebetso tse fapaneng.Likarolo tsena li kenyelletsa:

- Katleho e Phahameng ea Filtration: Taolo e nepahetseng ea boholo ba pore e lumella ho hloekisa ka katleho ho fihlela maemong a submicron, ho netefatsa ho tlosoa ha litšila le litšila tse tsoang mokelikeli le likhase.

- Durability le Matla: Sintering process bonds likaroloana tsa tšepe, ho fana ka matla a mochine le ho hanyetsa deformation, esita le tlas'a maemo a thata.

- Bophara ba Mocheso le Khatello ea Khatello: Li-tubes li ka sebetsa libakeng tse feteletseng, li boloka botšepehi ba sebopeho le katleho ea ho hloekisa ho pholletsa le mefuta e mengata ea mocheso le likhatello.

- Tšebelisano ea Lik'hemik'hale: Ha li na lik'hemik'hale 'me ha li khone ho bola, li etsa hore li tšoanelehe bakeng sa ho sefa lik'hemik'hale tse mabifi le mecha ea litaba e senyang.

- Ho hloeka le ho Ts'ebelisoa hape: Li-tubes tsa tšepe tse nang le porous sintered li ka hloekisoa habonolo le ho sebelisoa hape hangata, ho fokotsa litšenyehelo tsa tlhokomelo le ho lelefatsa bophelo ba sefe.

2. Li-tubes tsa tšepe tse porous sintered li sebetsa joang e le li-filters?

Ho sebetsa ha li-tubes tsa tšepe tse nang le porous sintered e le li-filters ho ipapisitse le sebopeho sa tsona sa masoba se hokahaneng.Ha mokelikeli kapa khase e phalla ka har'a tube, litšila le likaroloana li nkoa ka har'a li-pores ha li ntse li lumella mokhoa o lakatsehang hore o fete.Boholo, kabo, le tlhophiso ea li-pores li khetholla bokhoni ba ho sefa le mofuta oa likaroloana tse ka ntšoang.Sintered metal's high porosity le li-pores tse ntle li thusa ho sefa ka katleho, ho etsa hore li-tubes tsena e be tse loketseng bakeng sa lits'ebetso tsa bohlokoa moo ho hlokahalang tlhoekiso e nepahetseng le e tšepahalang.

3. Ke lintlha life tse lokelang ho nahanoa bakeng sa ho kenya li-tubes tsa tšepe tse porous sintered tsamaisong?

Ho kenya ts'ebetso e nepahetseng ho bohlokoa ho netefatsa ts'ebetso e nepahetseng ea li-tubes tsa tšepe tse nang le porous sintered.Lintlha tse ling li kenyelletsa:

- Tiiso e Nepahetseng: Netefatsa likhokahano tse sireletsehileng le tse se nang ho lutla lipheletsong tse peli tsa tube ho thibela ho feta le ho boloka ts'ebetso e ntle ea ho sefa.

- Maikutlo: Beha tube ka nepo ho netefatsa hore tataiso ea phallo e lumellana le ts'ebetso ea eona e etselitsoeng, ebang ke ea ho sefa, ho kenya moea kapa ho ntša metsi.

- Tšehetso le Tšireletso: Fana ka tšehetso e lekaneng le tšireletso ho thibela tšenyo ea li-tubes nakong ea ho kenya le ho sebetsa.

4. Ke lits'ebetsong life tse ka sebelisoang li-tubes tsa tšepe tse nang le porous sintered?

Li-tubes tsa tšepe tse nang le porous sintered li fumana lits'ebetso ho liindasteri tse fapaneng, ho kenyelletsa:

- Petrochemicals le ho Hloekisa:Bakeng sa ts'ehetso ea li-catalyst, tlhoekiso ea maro a tšebetso, le ts'ebeliso ea phallo ea khase.

- Meriana:Litsing tsa moea tse hloekisitsoeng, tlhoekiso ea khase, le lits'ebetsong tsa phano ea lithethefatsi.

- Phekolo ea Metsi:Bakeng sa ho hloekisa metsi a litšila, ho kenya moea le ho sefa metsi a nooang.

- Sepakapaka:Litsing tsa mafura le tsa hydraulic bakeng sa ho tlhotla le ho kenya moea.

- Likoloi:Taolong ea mosi, tlhoekiso ea mafura, le lits'ebetso tsa lubrication.

- Lijo le Seno:Bakeng sa seno sa carbonation, aeration, le filtration ea mouoane.

5. Li-tubes tsa tšepe tse nang le porous sintered li kenya letsoho joang ho sebetsa hantle le ts'ebetsong ea tsamaiso?

Li-tubes tsa tšepe tse nang le porous sintered li ntlafatsa ts'ebetso le ts'ebetso ea sistimi ka:

- Ho netefatsa ts'ebetso e phahameng ea tlhoekiso, e lebisang ho maro a hloekileng le a hloekisitsoeng ho feta kapa likhase.

- Ho fana ka kabo ea phallo e ts'oanang, ho thibela kananelo kapa kabo e sa lekanang ea khatello.

- Ho mamella maemo a thata, ho fokotsa nako le litšenyehelo tsa tlhokomelo.

- Ho fana ka ts'ebetso ea ho hasana ha khase le ho ntša metsi, ho ntlafatsa karabelo ea lik'hemik'hale le ts'ebetso ea phetisetso ea bongata.

6. Ke mehato efe ea ho laola boleng e sebelisoang nakong ea ho etsoa ha li-tubes tsa tšepe tse nang le porous sintered?

HENGKO e le baetsi ba Top Sintered Metal Filter ba kenya tšebetsong mehato e thata ea taolo ea boleng nakong eohle ea tlhahiso.Sena se kenyelletsa:

- Boleng ba lintho tse bonahalang: Ho sebelisa likaroloana tsa tšepe tsa boemo bo phahameng ho netefatsa matla a mochine le khanyetso ea lik'hemik'hale.

- Taolo ea Boholo ba Pore: Taolo e nepahetseng ea li-parameter tsa sintering ho fihlela boholo bo lakatsehang ba pore le kabo.

- Ho nepahala ha Dimensional: Ho netefatsa mamello e tiileng ho fihlela litlhoko tsa bareki.

- Teko ea Ts'ebetso: Ho etsa liteko tsa ts'ebetso ea filthara, liteko tsa ho theoha ha khatello, le liteko tsa matla a mochini.

Bakeng sa litharollo tsa motho ka mong le tse sebetsang hantle tsa OEM Porous Metal Tubes, ikopanye le HENGKO kajeno hoka@hengko.com.

Sehlopha sa rona sa litsebi se ikemiselitse ho u thusa ho hlophisa tharollo e phethahetseng ea ho sefa bakeng sa litlhoko tsa hau tse ikhethileng.Hore na

ke bakeng sa ho sefa, ho hasana ha khase, ho ntša metsi, kapa ts'ebeliso efe kapa efe, re na le boiphihlelo le boiphihlelo ba ho fana.

li-tubes tsa tšepe tsa boleng bo holimo tse fihlelang litlhoko tsa hau.

Seke oa tsilatsila ho ikopanya le rona bakeng sa lipuisano lere lumelle re u thuse ho ntlafatsa sistimi ea hau ea filthara kapa projeke.

Re romelle lengolo-tsoibila hoka@hengko.comjoale 'me u nke mohato oa peleho lebisa katlehong e ntlafetseng le tshebetso ka

HENGKO's QualitySintered tšepe tube.