-

Filtration ea Catalyst e nang le Lisefe tsa Lekhasi Sintered Metal Mesh Filter Disc bakeng sa Pholiso ...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

tšepe e sa hloekang 316 316L terata mesh tube / cartridge filter e sebelisetsoang bongaka ...

HENGKO sintered wire mesh tube/cartridge filters hangata e sebelisetsoa ho hloekisa le ho sefa metsi le khase, karohano le ho hlaphoheloa ha particl e tiileng...

Sheba lintlha -

304 316 316L 304 316 316L li-cartridge tsa mesh tsa tšepe tse sa hloekang tse tsoang HENGKO

E entsoe ka strained ea 316 kapa 304 stainless steel strainer e nang le likarolo tse ngata, e na le thepa ea ho hanyetsa mocheso, ho hanyetsa khatello, le ho hanyetsa kutu.

Sheba lintlha -

316 316L terata letlooeng la mesh poleiti e ngata / filthara ea disc...

Lifilimi tsa HENGKO sintered wire mesh li na le likarolo tse 5 tsa terata tse sirelelitsoeng tse nang le meaho e ikemetseng bakeng sa matla a mochini o matla le mocheso o phahameng...

Sheba lintlha -

Sefaele sa terata sa terata sa 316 SS sa terata sa kakaretso sa bongaka sa micron bakeng sa meriana...

Li-filters tsa tšepe tse sa hloekang tsa HENGKO hangata li sebelisoa ho hloekisa le ho sefa metsi le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, ...

Sheba lintlha -

Khatello e phahameng e hanyetsanang le 316l sintered steel mesh filter cartridge

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho khutlisa karolo e tiileng, pholiso ea phefumoloho ...

Sheba lintlha -

Sesefa sa filthara ea tšepe e sa hloekang ea terata ea letlooeng bakeng sa sefe ea kofi kapa moea oa moea...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

Sintered stainless steel wire mesh air filter cartridge bakeng sa ho tlosa lerole kapa metsi a hloekileng

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

Sintered seamless stainless 304/316L phala e sefang ea terata bakeng sa sistimi ea tlhoekiso

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

Customized 304/316L sintered tšepe terata letlooeng filter bakeng sa indasteri & Lab f...

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

90 100 Micron sintered porous tšepe filthara silindara terata strainer,...

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

2 5 50 100 150 300 Microns porous 304 316L SS tšepe e sa hloekang terata sintered letlooeng filter...

Mesh e entsoeng ka tšepe e sa hloekang e entsoe ka mesh e lohiloeng ka tšepe e sa hloekang, 'me ts'ebetso ea welding ea argon-arc e kopanya bokaholimo ba tiiso ea karolo ea sefe. ...

Sheba lintlha -

Round 25 50 100 micron sintered stainless steel mesh filter disc

Li-filters tsa HENGKO sintered disc li na le marang-rang a ts'oanang, a hokahaneng a li-pores tse nang le litselana tse bohloko tse tšoasang likaroloana tse tiileng ka har'a khase kapa metsi. Feta...

Sheba lintlha -

Oli e ka tloahelehang kapa moea o tlhotliloeng ka tšepe e se nang tšepe letlooeng filthara ea bleeder orifice valve

Lifilimi tsa HENGKO sintered wire mesh hangata li sebelisetsoa tlhoekiso le ho sefa metsi le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, transpirati...

Sheba lintlha -

40 micron sintered 316L tšepe filthara silindara mesh / phofo element

Li-filters tsa Sintered wire mesh hangata li sebelisetsoa tlhoekiso le ho sefa metsi le khase, karohano le ho khutlisa likaroloana tse tiileng, phepelo e pholileng ...

Sheba lintlha -

Reusable Resists High Temperature Microns Mesh Sintering Metal Filter Cartridge

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

Mofuta oa kerese Sintered 316L tšepe letlooeng filthara khatriji reusable

HENGKO e fana ka pokello e pharalletseng ea li-cartridge tsa tšepe tse se nang tšepe tse etselitsoeng ho sebelisoa liindasteri tse fapaneng, ho kenyeletsoa le lik'hemik'hale tsa petrole ...

Sheba lintlha -

Customized micron sintered porous tšepe silindara letlooeng filter tube bakeng sa o...

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

Sintered 5 10 40 100 microns porous 316L tšepe filthara terata letlooeng bakeng sa lerōle filthara

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha -

5 40 micron sintered tšepe e sa hloekang porous tšepe mafura oli / moea / lerole filtara terata letlooeng ca...

Li-filters tsa Sinter wire mesh hangata li sebelisetsoa tlhoekiso le tlhoekiso ea mokelikeli le khase, karohano le ho hlaphoheloa ha likaroloana tse tiileng, pholiso ea transpiration...

Sheba lintlha

Sintered mesh ke eng?

Ho bonolo ho re, Sintered mesh ke sefe ea tšepe e entsoeng ka ho kopanya likarolo tse ngata tsa mesh e lohiloeng.

ka mokgoa o bitsoang sintering.

Nakong ea sintering, lihlopha tsa mesh li futhumatsoa 'me li hatelloa hammoho, li etsa mohaho o matla le o tsitsitseng.

Sehlahisoa se hlahisoang se na le boholo bo lekanang ba pore mme se fana ka bokhoni bo botle ba ho sefa, se etsa hore se loketse

likopo tse fapaneng liindastering moo ho hlokahalang tlhoekiso e nepahetseng le e tšepahalang.

Hobaneng ha U Sebelisa Sintered Stainless Steel Mesh?

Sintered stainless steel mesh e fana ka melemo e mengata e etsang hore e be khetho e nepahetseng bakeng sa lits'ebetso tse fapaneng tsa indasteri:

1.Ho tšoarella:

Sintered stainless steel e hanyetsana haholo le kutu, e etsa hore e tšoanele libaka tse thata le tšebeliso e telele.

2.Tlhahiso e Phahameng ea Filtration:

Ts'ebetso ea sintering e etsa hore ho be le sebopeho sa pore se ts'oanang se lumellang ho sefa ka katleho ha likaroloana, ho fana ka katleho e phahameng ea ho hloekisa bakeng sa metsi le likhase.

3.Customizable Pore Sizes:

Baetsi ba ka etsa li-meshes tse sintered tse nang le boholo bo fapaneng ba pore ho fihlela litlhoko tse khethehileng tsa ho sefa, ho etsa hore li feto-fetohe bakeng sa lits'ebetso tse fapaneng.

4.Mechanical Matla:

Sintered stainless steel mesh e tiile 'me e khona ho mamella likhatello tse phahameng, mocheso le sekhahla sa phallo ntle le ho holofala.

5.Ho bonolo ho Hloekisa:

Li-meshes tsena li ka hloekisoa ka mekhoa e fapaneng (mohlala, ho ts'oaroa ha mokokotlo, ho hloekisa ka ultrasonic), e leng ho eketsang nako ea bophelo ba bona le ho boloka ts'ebetso.

6.Ho hanyetsa lik'hemik'hale:

Li khona ho sebetsana le mefuta e mengata ea lik'hemik'hale, e leng se etsang hore li tšoanelehe bakeng sa ho sebelisoa ha ho etsoa lik'hemik'hale, lijo le lino, le indasteri ea meriana.

7.Non-chefo le Sireletsehile:

Kaha li entsoe ka tšepe e sa hloekang, ha li na chefo 'me ha li kenye lintho tse kotsi ka thepa e entsoeng.

8.Litšenyehelo-Ka katleho:

Le hoja letsete la pele le ka 'na la e-ba holimo, ho tšoarella le ho sebelisoa hape ha mesh ea tšepe e sa hloekang e ka lebisang ho bolokeng litšenyehelo tsa nako e telele.

9.Likopo ho Liindasteri tse sa tšoaneng:

Li sebelisoa mafapheng a fapaneng, ho kenyelletsa kalafo ea metsi, oli le khase, meriana le phepelo ea lijo, ka lebaka la ho feto-fetoha ha tsona le ho ts'epahala.

Litšobotsi tsena li etsa hore mesh ea tšepe e sa hloekang e be khetho e ntle haholo bakeng sa liindasteri tse hlokang tharollo ea ts'ebetso e phahameng ea ts'ebetso.

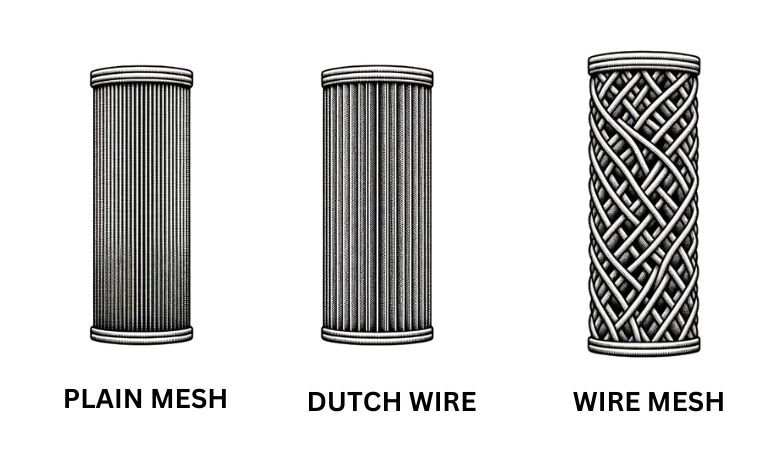

Mefuta ea Sefe ea Sintered Mesh ?

Li-filters tsa Sintered mesh li tla ka mefuta e fapaneng ho latela sebopeho sa tsona, likarolo le lits'ebetso tse ikhethileng. E meng ea mefuta e tloaelehileng e kenyelletsa:

1. Layer Sintered Mesh:

E entsoe ka lera le le leng la mesh e lohiloeng ea terata e sirelelitsoeng ho matlafatsa matla le ho tiea ha eona.

2. Multi-layer Sintered Mesh:

Sena se akarelletsa ho bokella likarolo tse 'maloa tsa letlooeng le lohiloeng ebe li li kopanya hammoho. Sebopeho sa mekhahlelo e mengata se matlafatsa matla a mochine le ho nepahala ha filtration.

3. Sintered Square Woven Mesh:

E entsoe ka likaroloana tsa mesh ea terata e kopantsoeng hammoho, mofuta ona o fana ka boholo bo lekanang ba pore 'me hangata o sebelisoa lits'ebetsong tse fapaneng tsa ho sefa.

4. Dutch Woven Sintered Mesh:

Sena se kopanya likarolo tse ngata tsa meshes ea terata e lohiloeng ea Madache, e ntan'o siloa. Sephetho ke sefe se nang le bokhoni bo botle ba ho sefa.

5. Perforated Metal Sintered Mesh:

Mofuta ona o kopanya karolo e le 'ngoe kapa ho feta ea letlooeng le lohiloeng ka tšepe e nang le perforated. Tšepe e nang le perforated e fana ka matla a eketsehileng, ha likarolo tsa terata li fana ka filtration.

6. Sintered Fiber Felt Mesh:

Ho e-na le terata e lohiloeng, sefe sena se sebelisa 'mete oa likhoele tsa tšepe. Likhoele li koaheloa 'moho ho etsa sebaka sa porous se setle haholo bakeng sa lisebelisoa tsa mocheso o phahameng le oa viscosity e phahameng.

7. Sintered Metal Powder Mesh:

Mofuta ona o entsoe ka li-porous metal powders ho etsa porous filtration medium. Hangata e sebelisoa ha ho hlokahala ho hloekisa hantle le ho boloka litšila tse phahameng.

E 'ngoe le e' ngoe ea mefuta ena e na le melemo ea eona 'me e etselitsoe lisebelisoa tse khethehileng. Ha u khetha filthara ea sintered mesh, ho bohlokoa ho nahana ka mofuta oa ntho e tlhotliloeng, boholo bo lakatsehang ba pore, maemo a ts'ebetso le lintlha tse ling tse amehang.

Mokhoa oa ho khetha li-filters tse nepahetseng tsa Sintered Mesh bakeng sa Sesebelisoa sa hau sa Filtration?

Ho khetha filthara e nepahetseng ea sintered mesh bakeng sa sesebelisoa sa hau sa ho sefa ho bohlokoa bakeng sa ts'ebetso e nepahetseng. Mona ke tataiso ea mohato ka mohato ho u thusa ho etsa qeto u na le tsebo:

1. Fumana Litlhoko tsa ho Filtration:

* Boholo ba Karolo: Utloisisa boholo ba karoloana e nyane haholo eo u hlokang ho e sefa. Sena se tla u tataisa ho khetha boholo bo nepahetseng ba pore ea letlooeng la sintered.

* Sekhahla sa Phallo: Nahana ka sekhahla se lakatsehang sa phallo ka sefe. Mefuta e meng ea mesh e lumella lebelo la phallo e potlakileng ntle le ho senya ts'ebetso ea ho sefa.

2. Lekola Maemo a Ts'ebetso:

Mocheso: Netefatsa hore mesh e khethiloeng ea sintered e khona ho mamella mocheso oa ts'ebetso ea ts'ebetso ea hau.

Khatello: Mekhoa e meng ea ho hloekisa e kenyelletsa khatello e phahameng. Khetha mesh e ka sebetsanang le likhatello tsena ntle le ho holofala.

Tšebelisano ea Lik'hemik'hale: Netefatsa hore thepa ea letlooeng e lumellana le lintho tse ntseng li tlhotloa, haholo-holo haeba lik'hemik'hale kapa lintho tse senyang li ameha.

3. Khetho ea Lintho:

Tšepe e sa hloekang ke lisebelisoa tse atileng haholo bakeng sa letlooeng la sintered ka lebaka la ho tšoarella ha eona le ho hanyetsa ho bola. Leha ho le joalo, lisebelisoa tse ling tse kang titanium kapa Monel li ka ba tse loketseng lits'ebetso tse ikhethileng.

4. Khetha Mofuta oa Sintered Mesh:

Single Layer vs. Multi-layer: Meshes e nang le mekhahlelo e mengata e fana ka matla a holimo le ho hloekisa ka mokhoa o nepahetseng haholoanyane empa e ka 'na ea e-ba boima ho feta lits'ebetso tse ling.

Woven vs. Non-Woven (Fiber Felt): Le hoja li-meshes tse lohiloeng li fana ka boholo ba pore bo lekanang, tse sa lohiloeng, tse kang fiber e ikutloang, li fana ka filtration e tebileng.

5. Nahana ka Tlhokomelo le Tlhoekiso:

Ke hangata hakae u tla hloka ho hloekisa kapa ho fetola sefe? Li-meshes tse ling tsa sintered li ka hlatsuoa habonolo, ha tse ling li ka hloka ho nkeloa sebaka ka mor'a nako e itseng.

6. Sheba Lintlha tsa Sefe:

Bokhoni ba ho sefa, boemo ba khatello e phatlohileng, le ho kenella habonolo ke lintlha tsa bohlokoa tse lokelang ho nahanoa. Netefatsa hore mesh e khethiloeng e kopana kapa e feta lintlha tse hlokahalang bakeng sa kopo ea hau.

7. Ikopanye le Baetsi kapa Litsebi:

Ho sebelisana le moetsi oa sintered mesh filter kapa setsebi ho ka fana ka lintlha tsa bohlokoa. Ba ka fana ka tlhahiso ea lihlahisoa tse ikhethileng kapa litharollo tse ikhethileng ho latela litlhoko tsa hau.

8. Maikutlo a Litšenyehelo:

Leha ho le bohlokoa ho fumana sefe e khahlang litlhoko tsa hau, ho bohlokoa hape ho leka-lekanya boleng le litšenyehelo. Nahana ka bobeli lichelete tsa pele le litšenyehelo tsa nako e telele tsa ts'ebetso.

9. Litifikeiti le Tiisetso ea Boleng:

Netefatsa hore moetsi o latela maemo a boleng joalo ka litifikeiti tsa ISO. Sena se tiisa ho ts'epahala le ho sebetsa ha li-filters tse sintered mesh.

Ka ho lekola litlhoko tsa hau ka hloko le ho buisana le litsebi, u ka khetha filthara e nepahetseng ea sintered mesh e netefatsang ho sefa hantle le ho phela halelele.

Sintered melt filthara vs Sintered porous metal filter ?

Li-filters tse sintered melt mesh le li-filters tsa tšepe tse entsoeng ka sintered li sebeletsa merero e fapaneng, leha ka bobeli li entsoe ka lits'ebetso tsa sintering.

Lisefa tsa Sintered Melt Mesh:

*Sebopeho: E entsoe ka lithapo tsa tšepe tse lohiloeng tse kopantsoeng hammoho ho etsa letlooeng.

*Kopo: Haholo-holo e sebelisetsoa ho hloekisa likaroloana tse kholoanyane le e le mokhoa oa ho tšehetsa mekhoa e meng ea ho hloekisa.

* Boholo ba Pore: Ka kakaretso e fana ka boholo bo boholo ba pore bo loketseng ho sefa mahoashe.

*Matla: E fana ka matla a matle a mochini mme hangata e sebelisoa lits'ebetsong moo ho tšoarellang ho leng bohlokoa.

Sintered Porous Metal Filters:

*Sebopeho: E entsoe ka li-pore tse sintered, tse hlahisang sebopeho sa pore se ts'oanang le se hokahaneng.

*Kopo: E loketse ho hloekisa hantle le ho hloekisa khase, e khonang ho hapa likaroloana tse nyenyane.

* Boholo ba Pore: E ka etsoa bakeng sa boholo bo khethehileng ba pore, e lumellang taolo e nepahetseng ea ho hloekisa.

* Ho feto-fetoha ha maemo: E loketse mefuta e mengata ea lisebelisoa, ho kenyelletsa le ho hloekisa metsi le khase liindasteri tse fapaneng.

Ka kakaretso, khetho pakeng tsa tse peli e itšetlehile ka litlhoko tse khethehileng tsa ho hloekisa, tse kang boholo ba likaroloana, litekanyetso tsa phallo, le mofuta oa kopo.

Mona re etsa tafole ea papiso bakeng sa li-filters tse sintered melt mesh le li-filters tsa tšepe tse entsoeng ka sintered:

| Sebopeho | Sesefa sa Sintered Melt Mesh | Sintered Porous Metal Filter |

|---|---|---|

| Sebopeho | Lithapo tse lohiloeng tsa tšepe li ne li sila hammoho | Sintered tšepe phofo |

| Kopo | Filtration e mahoashe, mokhoa oa ho tšehetsa | Filtration e ntle, ho hloekisa khase |

| Boholo ba Pore | Li-pore tse kholoanyane | E etselitsoe boholo bo khethehileng ba pore |

| Matla | Matla a matle a mochini | High durability le ho hanyetsa |

| Matla a ho Sefa | Katleho e tlase bakeng sa likaroloana tse nyane | Bokhoni bo phahameng bakeng sa likaroloana tse nyane |

| Ho feto-fetoha ha maemo | E lekanyelitsoe lits'ebetsong tse ikhethileng | E loketse liindasteri tse fapaneng |

| Tlhokomelo | Ho bonolo ho hloekisa | E ka hloekisoa ho sebelisoa mekhoa e mengata |

Kopo

Mona ke tse ling tsa lits'ebetso tse tsebahalang tsa li-filters tse sintered mesh, hammoho le litlhaloso tse qaqileng bakeng sa e 'ngoe le e 'ngoe:

1. Tlhahiso ea Meriana le Biotech:

* Tlhaloso: Liindastering tsa meriana le tsa biotech, bohloeki ba lihlahisoa bo bohlokoa haholo. Lisefa tsa Sintered mesh li bapala karolo ea bohlokoa ho netefatsa bohloeki bona ka ho tlosa litšila le litšila. Li sebelisoa lits'ebetsong tse kang sterile air filtration, venting, le cell culture media preparation. Thepa ea bona e sa sebetseng le bokhoni ba ho etsoa sterilized li etsa hore e be tse loketseng lits'ebetso tsena tse hlokolosi, ho netefatsa ts'ebetso ea sehlahisoa le polokeho ea mokuli.

2. Petrochemical Processing:

* Tlhaloso: Indasteri ea petrochemical e sebetsana le maro a fapaneng, ao bongata ba ona e leng li-viscous kapa a nang le litšila. Lisefe tsa sintered mesh li arola hantle likaroloana tse sa batleheng, tse nolofalletsang tlhahiso ea mafura a boleng bo holimo, mafura le lihlahisoa tse ling tsa lik'hemik'hale. Ka lebaka la mocheso oa bona o phahameng oa mocheso le khatello ea khatello, li-filters tsena li boetse li loketse maemo a feteletseng a ho sebetsa a tloaelehileng indastering ena.

3. Tlhahiso ea Lijo le Lino:

* Tlhaloso: Ho netefatsa bohloeki le polokeho ea lisebelisoa ke ntho e tlang pele tlhahisong ea lijo le lino. Li-filters tsa Sintered mesh li thusa ho sefa likaroloana tse sa batleheng, libaktheria le litšila tse ling tse tsoang linong tse kang lero, veine le syrups. Li boetse li sebelisoa ho kenya lisebelisoa ho netefatsa hore moea o hloekisitsoeng o kena ka litanka tse belisoang kapa likepeng tsa polokelo.

4. Phekolo ea Metsi:

* Tlhaloso: Ho fihlella metsi a hloekileng ho bohlokoa bakeng sa ts'ebeliso le lits'ebetso tsa indasteri. Li-filters tse sintered mesh li thusa ho tlosa likaroloana, libaktheria le litšila tse ling mehloling ea metsi, ho netefatsa hore metsi a nooa a bolokehile le ho hloekisa metsi a litšila. Ho thibela ho bola ha tsona ho molemo haholo ha ho sefa metsi a letsoai kapa a hloekisitsoeng ka lik'hemik'hale.

5. Libethe tsa Fluidized in Chemical Processing:

* Tlhaloso: Libethe tse nang le metsi li sebelisoa lits'ebetsong tse fapaneng tsa lik'hemik'hale moo likaroloana tse tiileng li hlokang ho emisoa mokelikeli. Li-filters tse sintered mesh li netefatsa phallo e ts'oanang ea moea kapa phallo ea mokelikeli, e etsa bonnete ba hore likaroloana li emisitsoe ka ho lekana, e leng sa bohlokoa bakeng sa karabelo e sa fetoheng ea lik'hemik'hale le boleng ba sehlahisoa.

6. Sefaufau le Sesefa sa Likoloi:

* Tlhaloso: Liindasteri tsa lifofane le tsa likoloi li hloka ho nepahala karolong e 'ngoe le e 'ngoe, ho kenyeletsoa ho sefa. Li-filters tse sintered mesh li sebelisoa lits'ebetsong tsa hydraulic, lits'ebetso tsa mafura le lits'ebetso tsa moea. Bokhoni ba bona ba ho mamella likhatello tse phahameng le ho hanela kutu bo etsa hore e be ba bohlokoa haholo libakeng tsena tse boima.

7. Tlhahiso ea Electronics le Semiconductor:

* Tlhaloso: Ha theknoloji e ntse e tsoela pele, tlhokahalo ea metsi a hloekileng haholo le moea ho elektronike le tlhahiso ea semiconductor e ba ea bohlokoa le ho feta. Li-filters tse sintered mesh li thusa ho fihlela bohloeki bona ka ho sefa likaroloana tsa sub-micron, ho netefatsa hore likarolo tsa elektronike tsa boleng bo holimo lia hlahisoa.

8. Likarolo tse Phefumolohang Ka har'a Mehaho ea Thepa:

* Tlhaloso: Likotla tsa lisebelisoa, joalo ka tsa lisebelisoa tsa motlakase kapa li-gearbox, hangata li hloka ho "hema" ho lekanya khatello kapa ho lokolla mocheso. Li-filters tse sirelelitsoeng ka har'a li-vents tse kenyang moea li netefatsa hore ha moea o feta, litšila tse kang lerōle kapa mongobo lia bolokoa, li sireletsa lisebelisoa tse ka hare.

E 'ngoe le e 'ngoe ea lits'ebetso tsena e bonts'a ho feto-fetoha le bokhoni ba lifilthara tse sintered mesh, e totobatsang bohlokoa ba tsona liindastering tse fapaneng.

LBH

Ke lisebelisoa life tse tloaelehileng tse sebelisoang bakeng sa letlooeng la sintered?

Lisebelisoa tse tloaelehileng li kenyelletsa tšepe e sa hloekang, nickel, titanium, boronse le li-polymer tse fapaneng.

Khetho ea thepa e itšetlehile ka lintlha tse kang ho lumellana ha lik'hemik'hale, ho hanyetsa mocheso, le matla a mochine.

Melemo ea li-filters tse sintered mesh ke life?

Li-filters tse sintered mesh li fana ka melemo e mengata, ho kenyelletsa:

* Porosity e phahameng le sekhahla sa phallo

*Bokhoni bo botle ba ho sefa

* Tšireletseho le bophelo bo bolelele ba tšebeletso

*Ho hana ho corrosion le abrasion

* Boholo ba pore bo ka khonehang bakeng sa lits'ebetso tse ikhethileng

Lisebelisoa

Lisebelisoa tse ling tse tloaelehileng tsa li-filters tsa sintered mesh ke life?

Li-filters tse sintered mesh li sebelisoa liindastering tse fapaneng, ho kenyelletsa:

* Ts'ebetso ea lik'hemik'hale

*Tlhahiso ea meriana

*Ho lokisa lijo le lino

*Tlhahiso ea tikoloho

* Sepakapaka le tšireletso

* Lisebelisoa tsa bongaka

Li-filters tsa sintered mesh li sebelisoa joang ts'ebetsong ea lik'hemik'hale?

Ts'ebetsong ea lik'hemik'hale, li-filters tse sintered mesh li sebelisetsoa:

*Sefero sa mokelikeli ho tlosa litšila le litšila

*Sefefo sa khase ho tšoara lintho tse itseng

* Tšehetso ea Catalyst bakeng sa karabelo ea lik'hemik'hale

Tlhahiso le Thepa

Sintered mesh e etsoa joang?

Sintered mesh hangata e etsoa ka mokhoa o kenyelletsang:

1. Ho lokisa phofo:

Metal kapa polymer powders li lokisoa ka kabo ea boholo bo lakatsehang.

2. Ho theha:

Li-powders li hatelloa ka sebopeho se lakatsehang ho sebelisa hlobo.

3.Sintering:

Thepa e entsoeng e futhumetse mocheso o phahameng ho kopanya likaroloana, ho theha sebopeho sa porous.

Ke lintlha life tse susumetsang boholo ba pore le porosity ea sintered mesh?

Boholo ba pore le porosity ea sintered mesh e ka laoloa ke:

* Boholo ba likaroloana:Likaroloana tse nyane hangata li baka li-pores tse nyane.

*Khatello nakong ea ho theha:Khatello e phahameng e ka fokotsa porosity.

* Sintering mocheso le nako:Mocheso o phahameng le linako tse telele tsa sintering li ka eketsa porosity.

Matla a mochini a sintered mesh a ka ntlafatsoa joang?

Matla a mochini a sintered mesh a ka ntlafatsoa ka:

* Ho sebelisa thepa e matla haholoanyane

* Ho eketsa mocheso oa sintering

*Eketsa sesebediswa se matlafatsang

Tlhokomelo le Tlhoekiso

Lisefe tsa sintered mesh li lokela ho hloekisoa le ho hlokomeloa joang?

Mekhoa ea ho hloekisa le ho hlokomela e itšetlehile ka ts'ebeliso e khethehileng le mofuta oa litšila tse tlhotliloeng. Mekhoa e tloaelehileng e kenyelletsa:

*Ho hlatsoa mokokotlo:Bakeng sa ho sefa metsi, ho qobella mokelikeli ho khutlela ka har'a sefe ka lehlakoreng le fapaneng.

*Sonication:Ho sebelisa maqhubu a ultrasonic ho tlosa litšila ho tloha sebakeng sa sefe.

* Ho hloekisa lik'hemik'hale:Ho sebelisa lisebelisoa tse nepahetseng tsa ho hloekisa ho qhaqha kapa ho tlosa litšila.

Ke matšoao afe a hore sefe ea sintered mesh e hloka ho nkeloa sebaka?

Matšoao a hore sefe ea sintered mesh e hloka ho nkeloa sebaka a kenyelletsa:

* Khatello e ntseng e eketseha

*Sekhahla sa phallo e fokotsehile

*Tšenyo e bonahalang kapa ho aparoa

*E fokotsehile ts'ebetso ea ho sefa

Iteanye le rona

U batla litharollo tse khethehileng tsa ho sefa?

Finyella ho HENGKO ka kotloloho hoka@hengko.comho OEM li-filters tsa hau tse ikhethang tsa sintered mesh.

Ha re sebetseng bokhabane hammoho!