-

Tloaelo ea 35 50 microns fuel filter sintered bronze filter disc disk bakeng sa mosebetsi o boima le ho ...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

Metal powder sintered porous porosity bronze 316 stainless steel micro filters discs

Sefate sa bronze se nang le porous sintered se entsoe ka phofo ea koporo ea alloy e sintered mocheso o phahameng. E na le ts'ebetso e phahameng ea ho sefa, moea o motle oa permeabili ...

Sheba lintlha -

Boiketlo ba motho ka mong 15 45 90 micron phofo sintered koporo boronse porous tšepe oli fi...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

porous tšepe filthara disc sekwere strainer micron sintered boro filtara lakane

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

sintered metal filter disc bakeng sa kalafo ea metsi a litšila, 5 20 micron 304 316L stainless ste...

Maqephe a tebileng a filthara a sebelisoa ho tlosa likaroloana tsa maro. Sena se bolela hore maro a ka hloeka, a hloekile kapa a sefuoa. Maqephe a sefa a loketse...

Sheba lintlha -

Sintered filthara likarolo le micron sintered porous tšepe boronse filtara disc

Hlalosa Sehlahisoa HENGKO e etsa lisebelisoa tsa sefahla ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo le sebapali ...

Sheba lintlha -

3 5 18 30 60 90 Micron porous sintered bronze air filter disc bakeng sa ho sefa liindasteri...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha -

R=11/30 limilimithara bophara 20 micron sintered multilayer boronse tšepe e sa hloekang sintered filte...

HENGKO e etsa lisebelisoa tsa filthara ka mefuta e mengata e fapaneng ea lisebelisoa, boholo le lisebelisoa hore li ka hlalosoa habonolo ka litšobotsi le tlhophiso...

Sheba lintlha

Tšebeliso e ka Sehloohong ea Sintered Metal Discs

Lits'ebetso tse 5 tsa mantlha tsa li-discs tsa tšepe tsa sintered:

* Filtration:

Li-discs tsa tšepe tse sintered li sebelisoa haholo lits'ebetsong tsa ho sefa ka lebaka la boholo ba tsona bo nepahetseng ba pore, ho kenella hantle, le matla a phahameng. Li ka sebelisoa ho sefa mefuta e fapaneng ea lintho, ho kenyelletsa le maro, likhase, esita le litšepe tse qhibilihisitsoeng. Ka mohlala, li sebelisoa ho sefa lino-mapholi, meriana, lik’hemik’hale, moea le metsi liindastering tse sa tšoaneng . Li ka etsoa ka mokhoa o ikhethileng hore li be le boholo bo fapaneng ba pore, ho latela ts'ebeliso e khethehileng ea filthara.

* Fluidization:

Li-discs tsa tšepe tsa sintered li sebelisoa lits'ebetsong tsa bethe tse nang le metsi, tse sebelisoang mekhoeng e fapaneng ea indasteri, joalo ka ho omisa, ho hlophisa le ho roala. Tsamaisong ea bethe e nang le metsi, khase e fetisoa betheng ea likaroloana, e leng se etsang hore likaroloana li itšoare joaloka mokelikeli. Li-discs tsa sintered metal li sebelisetsoa ho aba khase ka mokhoa o ts'oanang ho pholletsa le bethe le ho thibela likaroloana hore li se ke tsa baleha.

* Licheso tsa mocheso:

Li-discs tsa tšepe tse sintered li ka sebelisoa e le li-exchangers tsa mocheso ka lebaka la conductivity ea tsona e phahameng ea mocheso le sebaka se seholo sa holim'a metsi. Lisebelisoa tsa mocheso li sebelisetsoa ho fetisetsa mocheso ho tloha mokelikeli o mong ho ea ho o mong. Li-disc tsa tšepe tse sirelelitsoeng li ka sebelisoa lits'ebetsong tse fapaneng tsa phapanyetsano ea mocheso, joalo ka sistimi e futhumatsang moea, li-radiator le li-boilers.

* Likarolo tsa Friction:

Li-discs tsa tšepe tse sintered li sebelisoa ka likarolo tse fapaneng tsa likhohlano, joalo ka lipoleiti tsa clutch le li-brake pads. Sintered tšepe discs ka etswa ho tloha mefuta e fapaneng ya thepa, ho akarelletsa le tšepe, koporo, le boronse. Thepa e khethehileng e sebelisoang e tla itšetleha ka thepa e lakatsehang ea likhohlano. Ka mohlala, li-disc tsa tšepe tse sintered li atisa ho sebelisoa ka lipoleiti tsa clutch hobane li matla ebile ha li senyehe.

* Ho fokotsa molumo:

Sintered metal discs e ka sebelisoa ho fokotsa molumo. Li ka sebelisoa lits'ebetsong tse fapaneng, joalo ka lienjineri tsa makoloi, lisebelisoa tsa motlakase le mechini ea indasteri. Sintered metal discs e ka monya maqhubu a molumo le ho fokotsa maemo a lerata.

Lintlha tse ka Sehloohong tsa Sintered Metal Discs

Sintered metal discs fana ka motsoako o ikhethang oa thepa e etsang hore e be ea bohlokoa lits'ebetsong tse fapaneng tsa indasteri. Mona ke tse ling tsa likarolo tsa bona tsa mantlha:

1. Porosity e Phahameng le Permeability:

* Li-discs tsa tšepe tsa sintered li entsoe ka phofo ea tšepe e hatelitsoeng ebe e futhumatsoa ho ea mocheso o phahameng ka tlas'a ntlha ea ho qhibiliha, e leng se etsang hore likaroloana li kopane hammoho. Ts'ebetso ena e etsa marang-rang a li-pores tse hokahaneng ho pholletsa le disc, ho lumella maro kapa likhase hore li fete ha li ntse li hapa likaroloana tse kholo ho feta boholo ba pore.

* Porosity ea disc e ka laoloa ka nepo nakong ea ts'ebetso ea tlhahiso, e nolofalletsang ho itlhophisa bakeng sa litlhoko tse khethehileng tsa ho sefa. Sena se lumella karohano e atlehileng ea lisebelisoa tse lakatsehang ho tsoa ho litšila tse sa batleheng.

2. Matla a Phahameng le Tšireletseho:

*Ho sa tsotellehe sebopeho sa tsona se nang le masoba, li-disc tsa sintered metal li bonts'a matla le ho tšoarella ho makatsang. Kamano pakeng tsa likaroloana tsa tšepe e etsa hore ho be le mohaho o matla o ka mamellang likhatello tse phahameng le khatello ea mechine.

*Sena se li etsa hore li tšoanelehe bakeng sa lits'ebetso tse batloang haholo libakeng tse thata, joalo ka ho sefa metsi a senyang kapa ho sebetsa tlas'a khatello e matla.

3. Ho Hanyetsa Mocheso o Ntle:

* Thepa e sebelisoang ho li-disc tsa tšepe tse sirelelitsoeng, joalo ka tšepe e sa hloekang kapa boronse, ka tlhaho li hanana le mocheso o phahameng. Ba ka sebetsa ka katleho libakeng tse chesang ntle le ho senya botšepehi ba bona ba sebopeho kapa ts'ebetso ea ho hloekisa.

Tšobotsi ena e li etsa hore li tšoanelehe bakeng sa lisebelisoa tse kenyelletsang maro a chesang, likhase kapa litšepe tse qhibilihisitsoeng.

4. Corrosion le Wear Resistance:

* Thepa e sebelisoang ka har'a li-disc tsa tšepe tse sirelelitsoeng hangata li bonts'a khanyetso e ntle ea ho bola le ho senyeha. Sena ke 'nete ka ho khetheha bakeng sa li-disk tsa tšepe tse sa hloekang, tse ka mamellang ho pepesehela lik'hemik'hale tse thata le libaka tse senyang.

* Ho hanyetsa hona ha kutu le ho apara ho netefatsa bophelo bo bolelele ba ts'ebeletso bakeng sa li-disc, ho fokotsa tlhoko ea ho nchafatsa khafetsa.

5. Reusability le Bohloeki:

* Li-disc tsa tšepe tse sirelelitsoeng li ka sebelisoa hape, 'me li fana ka monyetla o sa sebetseng hantle le oa tikoloho. Li ka hloekisoa habonolo le ho hlatsuoa ka morao, ho lumella ho sebelisoa khafetsa lits'ebetsong tsa ho sefa.

* Ts'ebeliso ena e fokotsa litšila le litšenyehelo tsa tlhokomelo ha e bapisoa le mecha ea litaba ea filthara.

6. Ho feto-fetoha ha maemo le ho Itloaetsa:

* Sintered tšepe discs ka etsoa ka libopeho tse sa tšoaneng, boholo, le boholo pore ho kopana le litlhoko tse itseng tsa dikopo tse fapaneng. Li ka boela tsa etsoa ka thepa e fapaneng, e 'ngoe le e' ngoe e fana ka thepa e ikhethang bakeng sa litlhoko tse khethehileng tsa ho sefa.

* Ho feto-fetoha hona ho ba etsa tharollo e feto-fetohang haholo bakeng sa mefuta e mengata e fapaneng ea lits'ebetso tsa ho sefa le karohano ea indasteri.

LBH

1. Ke mefuta efe e fapaneng ea li-filters tsa sintered metal disc?

Li-filters tsa sintered metal disc li ka aroloa ho latela lintlha tse 'maloa:

* Boitsebiso:

Ts'epe e sa hloekang ke thepa e atileng haholo ka lebaka la ho hanyetsa ha eona ho hoholo, matla,

le mefuta e mengata ea mocheso o sebetsang. Lisebelisoa tse ling li kenyelletsa boronse, nickel, esita le lisebelisoa tse sa tloaelehang

joalo ka Hastelloy bakeng sa tikoloho e senyang haholo.

* Porosity le boholo ba pore:

The porosity e bolela peresente ea sebaka se se nang letho ka har'a sefe, ha boholo ba pore

e khetha karolo e nyane ka ho fetisisa eo filthara e ka e hapang. Li-filters li fumaneha ka mefuta e mengata ea li-porosity

le boholo ba pore, ho tloha ho li-micron ho ea ho limilimithara, ho lumellana le litlhoko tse fapaneng tsa ho hloekisa.

* Palo ea mekhahlelo:

Li-disc tsa lera le le leng li fana ka litefiso tse phahameng tsa phallo empa matla a fokolang a ho ts'oara litšila. Multi-layer

li-discs li na le boholo ba pore, tse fanang ka tlhoekiso e ntle le matla a phahameng a ho boloka litšila ha li ntse li boloka.

likhahla tse amohelehang.

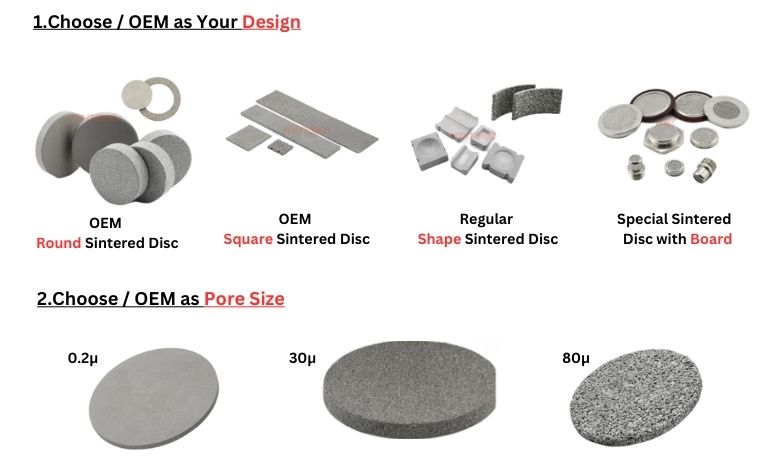

* Sebopeho:

Le hoja li-discs e le sebopeho se tloaelehileng ka ho fetisisa, li-filters li ka boela tsa etsoa ka libopeho tse sa tšoaneng

joalo ka lisekoere, likhutlo li tharo, lisilindara, kapa esita le libopeho tse khethehileng tsa geometri bakeng sa lits'ebetso tse ikhethileng.

2. Melemo le melemo ea ho sebelisa li-filters tsa sintered metal disc ke life?

Melemo:

* Matla a phahameng le ho tšoarella nako e telele: Li khona ho mamella likhatello tse phahameng, mocheso le tikoloho e thata.

* Filtration e nepahetseng le e tsitsitseng: Boholo bo sa fetoheng ba pore bo netefatsa karohano e tšepahalang ea lisebelisoa tse lakatsehang ho tsoa ho litšila tse sa batleheng.

* Versatility: E fumaneha ka lisebelisoa tse fapaneng, li-porosity, boholo ba pore le libopeho ho fihlela litlhoko tse fapaneng tsa ts'ebeliso.

* Ho sebelisoa hape le ho hloeka: Li ka hloekisoa habonolo le ho sebelisoa hape, ho fokotsa litšila le litšenyehelo tsa tlhokomelo.

* Thermal conductivity e phahameng: E loketse lits'ebetso tse kenyelletsang phetisetso ea mocheso.

Mefokolo:

* Theko ea pele e holimo ha e bapisoa le li-filters tse ling tse lahliloeng.

* E ka koala ka likaroloana tse ntle haholo, tse hlokang ho hloekisoa khafetsa kapa ho hlatsuoa ka morao.

* Ha e loketse lino tse nang le viscous haholo ka lebaka la meeli e ka bang teng ea sekhahla sa phallo.

3. Ke khetha sefe se nepahetseng sa sintered metal disc bakeng sa kopo ea ka?

Ho khetha filthara e nepahetseng ho hloka ho ela hloko lintlha tse 'maloa:

* Thepa ea mokelikeli: Mofuta oa mokelikeli o tlhotliloeng (mokelikeli, khase, joalo-joalo) le viscosity ea oona.

* Boholo le mofuta oa likaroloana: Boholo le litšobotsi tsa likaroloana tseo u batlang ho li hapa.

* Sekhahla sa phallo e lakatsehang: Sekhahla se hlokahalang sa phallo ea mokelikeli ka sefeng.

* Khatello ea ho sebetsa le mocheso: Khatello le mocheso oo filthara e tla kopana le ona nakong ea ts'ebetso.

* Tšebelisano ea lik'hemik'hale: Ho lumellana ha thepa ea sefa le maro a ntseng a sefuoa.

* Litlhoko tsa lichelete le ho sebelisoa hape: Litsenyehelo tsa pele khahlano le ho boloka litšenyehelo tsa nako e telele ka ho sebelisoa hape.

Ho buisana le setsebi sa filtration kapa moetsi oa sefe ho khothaletsoa ho etsa bonnete ba hore o khetha sefe se nepahetseng sa sintered metal disc bakeng sa ts'ebeliso ea hau e ikhethileng.

4. Ke hloekisa le ho boloka li-filters tsa sintered metal disc joang?

Mokhoa oa ho hloekisa o ipapisitse le mofuta oa sefe, lintho tse silafatsang tse tlhotliloeng, le likhothaletso tsa moetsi. Mekhoa e tloaelehileng ea ho hloekisa e kenyelletsa:

* Ho hlatsuoa ka morao: Ho qobella mokelikeli o hloekileng ka sefahla ka lehlakoreng le ka morao ho lahla likaroloana tse qabeletsoeng.

* Ho hloekisoa ha Ultrasonic: Ho sebelisa maqhubu a molumo ho theola likaroloana tse tsoang ho li-filter pores.

* Ho hloekisa lik'hemik'hale: Ho sebelisa litharollo tse khethehileng tsa ho hloekisa tse tsamaellanang le lisebelisoa tsa sefa mme li bolokehile bakeng sa ts'ebeliso e reriloeng ea sehlahisoa se tlhotliloeng.

Ho bohlokoa ho latela litaelo tsa moetsi bakeng sa tlhoekiso e nepahetseng le tlhokomelo ho netefatsa ts'ebetso e nepahetseng le bophelo bo bolelele ba filthara ea sintered metal disc.

5. Nka fumana boitsebiso bo eketsehileng hokae ka sintered metal disc filters?

Lisebelisoa tse 'maloa li teng ho ithuta haholoanyane ka li-filters tsa sintered metal disc:

* Liwebosaete tsa baetsi ba lifilimi:

Boholo ba bahlahisi ba fana ka leseli le felletseng mabapi le lihlahisoa tsa bona, ho kenyeletsoa litlhaloso, litataiso tsa ts'ebeliso, le lisebelisoa tsa tekheniki.

* Lingoliloeng tsa indasteri le liwebsaete:

Lingoliloeng tsa khoebo le liwebsaete tse shebaneng le theknoloji ea filtration hangata li na le lingoliloeng le lisebelisoa tse buang ka mefuta e fapaneng ea filthara, ho kenyeletsoa li-disk tsa tšepe tse sintered.

* Mekhatlo ea boenjiniere le ea ho sefa:

Mekhatlo ea profeshenale e joalo ka American Filtration & Separations Society (AFSS) e fana ka lisebelisoa tsa thuto le tlhaiso-leseling mabapi le mahlale a fapaneng a ho sefa.

Ka ho nahana ka Lipotso tsena le ho batla lintlha tse ling, u ka etsa qeto e nepahetseng mabapi le hore na li-filters tsa sintered metal disc ke tharollo e nepahetseng bakeng sa litlhoko tsa hau tsa ho sefa.

ITEANYE LE RONA

Notlolla bokhoni ba lisebelisoa tsa hau ka li-disc tsa tšepe tse siling tsa OEM tse tsoang ho HENGKO.

Re romelle lengolo-tsoibila kajeno hoka@hengko.comho hlahloba bokhoni ba rona ba tlhahiso e tsoetseng pele le

nka mohato oa pele ho ts'ebetso le boleng bo phahameng.

Ha re theheng ntho e ikhethang hammoho. Ikopanye le rona hona joale!