-

Filter Regulator bakeng sa Diaphragm Pump Accessories

Filter Regulator bakeng sa Diaphragm Pump Accessories Mona ho u fa malebela a ka a mabeli a theknoloji ka ho sebelisa selaoli se nang le litekanyetso tsa pneumatic actuator ke ntho e ntle haholo...

Sheba lintlha -

Li-valve tsa Tsela e le 'ngoe bakeng sa Phokotso ea Bolumo ba Matšoafo a Bronchoscopic

Li-valve tsa Tsela e le 'ngoe bakeng sa Phokotso ea Bolumo ba Matšoafo ea Bronchoscopic Mekhoa e meng ea Bronchoscopic ho e-na le opereishene ea ho fokotsa molumo oa matšoafo (LVRS) e sa tsoa sisinngoa; ea...

Sheba lintlha -

Filter ea Sintered Cartridge bakeng sa Polysilicon

Sintered cartridge filter bakeng sa tlhahiso ea polysilicon HENGKO sintered metal filters e fana ka moea o hloekileng, oo le oona o ntlafatsang bophelo ba batho, o sireletsa mohlahlobisisi...

Sheba lintlha -

Sesefa sa Steam bakeng sa Indasteri ea Mouoane

Sesefo sa Mouoane bakeng sa Indasteri ea Mouoane Sesebelisoa sa bohlokoahali se tsamaisang mecha ea litaba Sefahla sa mouoane ke sesebelisoa sa bohlokoa haholo ho pipeli...

Sheba lintlha -

Monocrystalline silicon pressure transmitter sintered metal porous filter disc

U sebelisa mochine o le mong oa crystal silicon piezoresistive technology pressure sensor, sebetsa indasteri ea tekanyo ea boemo ba mokelikeli lisebelisoa tsa sintered filter disc:...

Sheba lintlha -

Sintered Stainless Stainless Stainless Sensor Housing bakeng sa Sensor ea Khatello

Ntlo ea sensor e ka aroloa ka mokhoa o bonolo ho sireletsa sensor ka boeona ka katleho, 'me ntlo ea sensor e na le ts'ebetso ea ho ts'oara le ho ts'oara ...

Sheba lintlha -

Air Compressor & Blower Silencers -E fokotsa lerata la lisebelisoa

Li-compressor le li-blower li ka fumanoa libakeng tse ngata tsa mosebetsi. Ka linako tse ling u kanna oa se tsebe le hore li teng haeba batho ba sebelisa li-silencer tse tlhotliloeng kapa moea ...

Sheba lintlha -

Sefe ea tšepe e rekisoang e rekisoang ka ho fetisisa Sintered Metal, Male Thread G1-1/2 kapa G2

3 5 Micron Sintered Pneumatic Exhaust Muffler Silencer/Diffuse air & Noise Reducer. Li-mufflers tsa moea tse entsoeng ka tšepe ea boleng bo holimo ea HENGKO li kopana le ...

Sheba lintlha -

Filter ea Khase e ka hare ho Mohala Sintered Filter bakeng sa Bolaoli ba Khatello ea Morao

Balaoli ba kotsing ea ho senyeha ho tsoa likarolong tsa tsamaiso. Kahoo lilaoli tse fokotsang khatello li fanoa ka mochini oa khatiso oa 20-100 µm 316 SS o ka nkeloang sebaka ...

Sheba lintlha -

Sesefa sa Mouoane Matlo a Sefe ea tšepe e sa Hlokang Mokelikeli Bakeng sa Ho Hlatsoa Moeeng o Hlatsoang, Mouoane le Mokelikeli.

Libakeng tsa tlhahiso, li-filters tsa tšepe tsa HENGKO le litharollo tsa moea tse hloekileng li bohlokoa ho sireletsa lits'ebetso tse tsoetseng pele kapa tse hlokolosi tsa tlhahiso...

Sheba lintlha -

Filter ea tšepe e nang le porous sintered ea ozone le moea o ka metsing

Mokhoa oa ho etsa li-disc tsa bophara bo boholo (80-300 mm) tsa litšepe tse sa hloekang le tse thibelang kutu li hlalosoa. Litšobotsi tsa i...

Sheba lintlha -

Sintered Porous Metal Leaf Disc Filter Bakeng sa Polymer Melt Industry

Lisefe tsa Leaf Disc le Solid Plate bakeng sa lits'ebetso tsa ho sefa tsa polymer tse chesang haholo. Leaf disc le li-filters tse tiileng tsa poleiti li etselitsoe ho h...

Sheba lintlha -

Setlhoa se Sintered se Hlatsoang Khase e Hloekileng Bakeng sa Lits'ebetso tse le 'Ngoe Tse Tlase tsa Phallo

Setlhopha se Sintered sa Setlhoeki sa Khase bakeng sa Likopo tse Leng, tse Tlase Phallo e Le 'ngoe E etselitsoe ho hloeka ho hoholo le lits'ebetso tsa bohloeki bo phahameng tse hlokang maemo a litšila...

Sheba lintlha -

Sefa sa Porous Metal Filter Media le OEM Sintered Stainless Steel Filter bakeng sa Khase ea Hydrogen

Mecha ea litaba ea porous metal filter ea boqapi ba hajoale e kenyelletsa yuniti e sefang e tlosang litšila ho khase ea haedrojene, le valve ea tsela e le 'ngoe e laolang ...

Sheba lintlha -

Porous Metal Sintered Mini Cylinder

Litšepe tse nang le porous ke e 'ngoe ea lisebelisoa tse ngata tse loketseng ho etsa li-bearings. Melemo ea Sintered Mini Cylinder Metals Powdered e na le palo e kholo ...

Sheba lintlha -

Lisebelisoa tsa Stainless Sintered Inline bakeng sa Tšireletso ea Karolo e Nyane ea Phallo ea Phallo

Likaroloana tse laolang phallo e nyane joalo ka lifilthara tsa inline sintered steel stainless steel hangata li kengoa moeeng, khase, vacuum le litsamaiso tsa phallo ea mokelikeli ho ...

Sheba lintlha -

Sintered In-line Metal Gas Filter bakeng sa Sisteme ea Tlhoekiso ea Khase ea Semiconductor

Lisefa tsa khase ea tšepe e kentsoeng ka har'a mohala li sebetsa ho leleka litšila tse kenyelletsang mongobo, oksijene, carbon dioxide, carbon monoxide, hydrocarbons le carbonyls tsa tšepe ka ...

Sheba lintlha -

Sintered 316l Stainless Steel Filter In-line Strainer Tri clamp Sanitary Filter bakeng sa Mil...

Sintered 316l Stainless Steel Filter In-line Strainer Tri clamp Sanitary Filter for Milk Filtration Milk ke e 'ngoe ea lisebelisoa tse nang le limatlafatsi tse ngata haholo. Ke...

Sheba lintlha -

Sintered metal round deep filter sheets bakeng sa tlhahiso ea oli ea cannabis

Filtration Ho hlahisoeng ha lihlahisoa tse tsitsitseng tsa cannabinoid ho sefa ke mohato oa bohlokoa. Ho tlosa boka, mafura le oli ho tloha mariha a mangata ...

Sheba lintlha -

Sintered porous metal filter disc 20 micron bakeng sa tlhoekiso ea Khase le tlhahlobo

Finyella Karohano e Ke keng ea Bapisoa ea Khase/Solids ka Li-disc tsa HENGKO tsa Sintered Stainless Steel Filter! Sistimi ea rona ea ho sefa, e nang le sintered stainless ...

Sheba lintlha

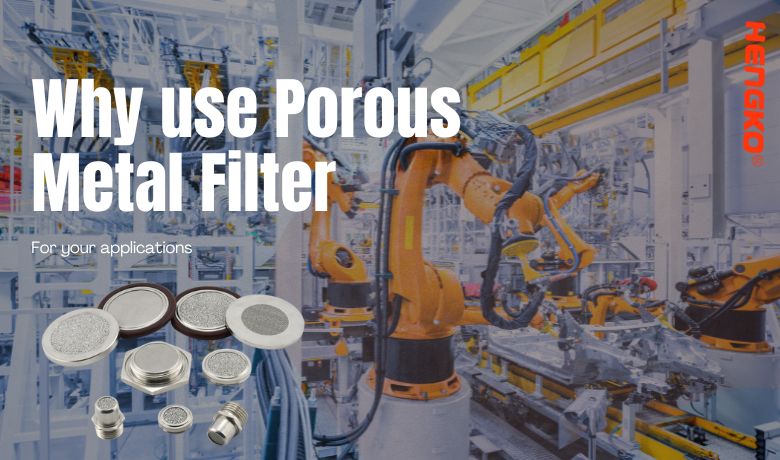

Hobaneng u sebelisa Sesefa sa Porous Metal bakeng sa projeke ea hau ea ho sefa?

Li-filters tsa tšepe tse nang le porous li fana ka melemo e mengata e ba etsang khetho e ntle bakeng sa merero e fapaneng ea ho sefa,

kahoo re thathamisa likarolo tse ling tsa mantlha, ka kopo sheba tse latelang:

1.High Durability le Matla:

Li-filters tsa tšepe tse nang le porous hangata li entsoe ka thepa e matla joalo ka tšepe e sa hloekang, e fanang ka boleng bo holimo

ho hanyetsa likhatello tse phahameng, khatello ea mocheso, le libaka tse senyang.

Sena se etsa hore li tšoanelehe bakeng sa lits'ebetso tsa indasteri moo ho tšoarellang ho leng bohlokoa.

2.Efficient Filtration:

Li-filters tsena li entsoe ka sebopeho sa pore se laoloang se nolofalletsang karohano e nepahetseng ea likaroloana,

esita le ka boholo bo nyane haholo. Taolo e nepahetseng holim'a kabo ea boholo ba pore e netefatsa ts'ebetso e tsitsitseng

ka ho hapa ditshila.

3.Bokhoni ba Mocheso o Phahameng:

Li-filters tsa tšepe li ka sebetsa ka katleho mocheso o phahameng haholo ho feta li-filters tse thehiloeng ho polymer, ho li etsa

e loketseng bakeng sa lits'ebetso tse kenyelletsang mocheso o phahameng, joalo ka indastering ea lik'hemik'hale le ea petrochemical.

4.Ho hanyetsa lik'hemik'hale: Li-filters tsa tšepe li hanana le mefuta e mengata ea lik'hemik'hale, e li lumellang hore li sebelisoe

lisebelisoa tse kenyelletsang lihlapolli tse matla, li-acids le li-bases ntle le ho senya.

5.Cleanability le Reusability:

Li-filters tsa tšepe tse nang le porous li ka hloekisoa le ho sebelisoa hape, e seng feela ho boloka chelete e ngata empa hape e fokotsa litšila.

Mekhoa e kang ho khutlela morao, ho hloekisa ka ultrasonic, le ho hloekisa lik'hemik'hale li ka tsosolosa matla a ho hloekisa.

6.Customizability:

Li ka etsoa enjene ho fihlela litlhoko tse khethehileng tsa ho sefa, ho kenyelletsa le libopeho tse fapaneng, boholo le lisebelisoa.

Mokhoa ona oa ho ikhethela o lumella litharollo tse hlophisitsoeng tse lumellanang le litlhoko tse khethehileng tsa ts'ebetso.

7.Sintered Metal Matla:

Sintering, mokhoa o sebelisoang ho etsa li-filters tse ngata tsa tšepe tse nang le porous, li kopanya likaroloana tsa tšepe hammoho ntle le ho qhibiliha

bona, e leng se bakang sebopeho se nang le masoba haholo empa se le matla se mamellang likhatello tsa mochini le mocheso hamolemo

hofeta balekane ba senang sintered.

Litšobotsi tsena li etsa hore li-filters tsa tšepe tse porous e be khetho e tšepahalang bakeng sa makala a kang meriana, lijo le lino,

aerospace, le tlhahiso ea indasteri, moo ts'ebetso e phahameng le ts'epo e hlokahalang.

Hobaneng o Khetha HENGKO bakeng sa Lisefa tsa Metal tse Sintered Porous?

HENGKO e fana ka mefuta e mengata ea likhetho ho fihlela litlhoko tse ikhethileng tsa projeke. Li-filters tsa rona li na le rekoto e netefalitsoeng indastering e fapaneng

lits'ebetso tse joalo ka ho sefa, ho fokotsa metsi, sparging, ts'ireletso ea sensor, taolo ea khatello, le tse ling.

Joaloka moetsi oa boleng bo holimo oa li-filters tse nang le porous metal sintered China, re fana ka tse latelang:

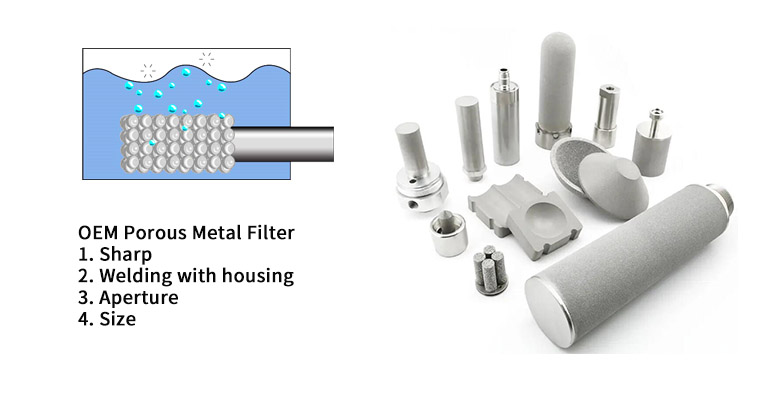

* Meetso e ikhethang ea OEMka boholo, boholo ba pore, lisebelisoa, mekhahlelo le libopeho

* Sehlopha sa litsebi tsa R&D bakeng sa tharollo ea phepelo e potlakileng le e sebetsang hantle

* Lihlahisoa tse fihlelang litekanyetso tsa CE tsa boleng le botsitso

* Ts'ebeletso e felletseng ho tloha ho boenjiniere ho isa ho tšehetso ea kamora thekiso

* Phihlelo e ruilengle Tsebo ea merero ea ts'ebeliso ea indasteri ea lik'hemik'hale, lijo le lino.

Tšebeliso ea Lihlahisoa tsa Sintered Porous Metal Filters

1. Ho sefa liindasteri tsa khase le metsi:

Li-filters tsa tšepe tse sirelelitsoeng li sebelisoa ho sefa metsi le likhase liindastering tse fapaneng tsa ts'ebetso, ho kenyeletsoa tlhahiso ea petrochemical, lik'hemik'hale le tsa meriana.

2. Lisebelisoa tsa bongaka tsa ho sefa le ho arola:

Lisefa tsa tšepe tse sirelelitsoeng li sebelisoa lisebelisoa tsa bongaka tse kang mechini ea dialysis, li-ventilator le lihloela tsa mali. Li-filters tsena li khethiloe bakeng sa ho nepahala ha tsona ho phahameng, boholo ba pore le sebopeho se sa fetoheng, le biocompatibility.

3. Sefello sa khase ea mosi oa likoloi:

Li-filters tsa tšepe tse sintered li sebelisoa lits'ebetsong tsa likoloi ho fokotsa mesi le ho ntlafatsa ts'ebetso ea enjine. Li ka sebelisoa ho sefa likaroloana le likhase tse tsoang mocheng oa metsi ho fokotsa tšilafalo ea moea.

4. Sefa lijo le seno:

Sintered porous metal filters li sebelisoa indastering ea lijo le lino ho sefa le ho hlakisa maro. Li bohlokoa haholo bakeng sa lits'ebetso tse kenyelletsang mocheso o phahameng, khatello e phahameng kapa lik'hemik'hale tse matla.

5. Mekhoa ea ho hloekisa metsi:

Li-filters tsa tšepe tse sintered li sebelisoa lits'ebetsong tsa kalafo ea metsi ho tlosa litšila, ho hloekisa metsi le ho ntlafatsa boleng ba metsi. Li ka boela tsa sebelisoa lits'ebetsong tsa ho hloekisa metsi a litšila ho arola lintho tse tiileng ho metsi.

6. Sistimi ea mafura ea sepakapaka:

Li-filters tsa tšepe tse entsoeng ka sintered li sebelisoa lits'ebetsong tsa mafura a moeeng ho netefatsa hore mafura ha a na litšila le ho sireletsa lipompo tsa mafura le liente. Li fana ka tlhoekiso e sebetsang hantle haholo, phallo e tsitsitseng, le ho theoha ha khatello e tlase.

7. Mekhoa ea tlhahiso ea Biopharmaceutical:

Li-filters tsa tšepe tse sintered li sebelisoa mekhoeng ea tlhahiso ea biopharmaceutical ho hlakisa le ho hloekisa metsi. Li bohlokoa haholo lits'ebetsong tse nang le litlhoko tse phahameng tsa sterilization le filtration.

8. Tokiso ea tikoloho le taolo ea tšilafalo:

Li-filters tsa tšepe tse sintered li sebelisoa tokisong ea tikoloho le taolong ea tšilafalo ho tlosa litšila tse tsoang moeeng, metsing le mobung. Li ka sebelisoa ho phekola metsi a ka tlas'a lefatše a silafetseng, ho tlosa litšepe tse boima melapong ea litšila, le ho fana ka moea o hloekileng libakeng tsa indasteri.

Engineered Solutions

Ho HENGKO, re na le rekoto e netefalitsoeng ea ho fana ka litharollo tse ikhethileng le tse sebetsang ho fetisisa

mathata a rarahaneng a ho sefa le ho laola phallo bakeng sa bareki lefatšeng ka bophara. Sehlopha sa rona sa R&D se ikemiselitse ho fana ka

tharollo e molemohali bakeng sa litlhoko tsa indasteri ea hau. Selekane le rona 'me re u fe tsebo ea rona ea ho sefa tšepe le

fana ka tharollo e molemohali bakeng sa merero ea hau.

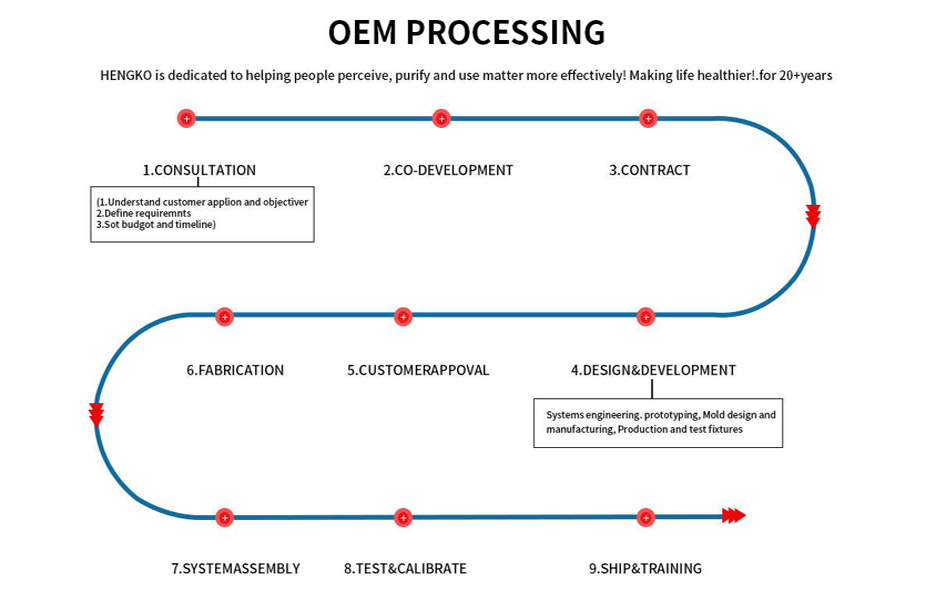

Mokhoa oa ho Customize Sintered Sintered Porous Metal Filters

Ho iketsetsa li-filthara tsa tšepe tsa Sintered Porous ka HENGKO

Haeba u na le litlhoko tse khethehileng tsa ho sefa 'me u sa khone ho fumana sehlahisoa se loketseng, ikopanye le HENGKO. Sehlopha sa rona

e tla sebetsa le uena ho fumana tharollo e molemohali. Mokhoa oa ho etsa li-filters tsa tšepe tsa sintered porous o kenyelletsa:

1.Ho ikopanya le HENGKO bakeng sa lipuisano

2.Nts'etsopele e kopanetsoeng

3.Ho saena konteraka

4.Moqapi le nts'etsopele

5.Teko ea bareki

6.Fabrication le tlhahiso ea bongata

7.Kopano ea tsamaiso

8.Teko le teka-tekano

9.Shipping le koetliso

HENGKO e nehetsoe ho thusa batho ho laola, ho hloekisa le ho sebelisa litaba ka katleho

lilemo tse fetang 20, ho etsa hore bophelo bo phele hantle.

HENGKO ke feme e tsebahalang ebile e na le boiphihlelo hosintered porous metal filters. Setsebi sa rona sa botekgeniki

lihlopha li tsepamisitse maikutlo ho nts'etsopele, ho rala le ho etsa lisebelisoa tsa boleng bo holimo tsa sintered porous metal

le lisebelisoa tsa porous, tse finyellang litlhoko tsa liindasteri tse sa tšoaneng le likopo. Ka phihlelo e pharaletseng

le botsebi, re thehile litšebelisano tsa maano le likhoebo tse ngata tsa theknoloji e phahameng le lilaboratori tsa bohlokoa

liunivesithing lefats'e ka bophara, ho ntlafatsa bokhoni ba rona ba ho fana ka litharollo tse ncha bakeng sa bareki ba rona.

Likarolo tsa Sintered Porous Metal Filters

1. Ho bonolo ho bopa, ho sebetsa, ho kopanya, le ho hloekisa.

2. E fana ka ho nepahala ha filtration ho tloha ho 0,2 ho isa ho 200 microns.

3. E na le matla a ho hloekisa le ho sebelisoa khafetsa.

4. E fana ka tšehetso ea motho ka mong bakeng sa mefuta e fapaneng ea lisebelisoa le litekanyo.

5. Ka tloaelo e sebelisoa libakeng tse nang le mocheso ho tloha ho 200°C ho isa ho 650°C (ho ea holimo ho 900°C) le

maemong a acid kapa alkali corrosion.

FAQ Tataiso ea Lisefe tsa Metal tse Sintered Porous :

Lisefa tsa tšepe tsa Sintered Porous ke eng?

Li-filters tsa tšepe tse sirelelitsoeng, tse boetseng li rehiloe li-filters tsa tšepe tse sainted, bakeng sa phepelo ea mantlha ea HENGKO 316L lifaele tsa tšepe tse se nang tšepe,

hobane ho na le masoba a manyane haholo ka har'a tšepe, e le hore khase le mokelikeli li fete le ho arola

litšila tse sa batleheng le lintho tse tiileng, hape hobane 316L tšepe e sa hloekang e ka fihlella boholo ba tlhoekiso e hlokahalang empa ka mokhoa o utloahalang.

theko bakeng sa boholo ba bareki. kahoo rea u amohela ho ikopanya le rona ho tseba lintlha tse ling.

Li-filters tsa Sintered li sebelisetsoa eng?

A:Bakeng sa li-filters tse sintered tse ts'oanang le tse ngata tse tloaelehileng, tse ka sehloohong ho arola litšila tse sa batleheng le lintho tse tiileng ho khase ea rona le

lisebelisoa tsa metsi, ho etsa hore khase ea rona e hloeke kamoo morero o hlokang kateng.

Na Sintered Metal Porous?

A:E, tšepe e entsoeng ka sintered e na le masoba ka hare, li-pores tse sa tloaelehang tsa micron, e le ho hloekisa litšila ka khase kapa metsi, e le hore

finyella sepheo sa tlhoekiso

Ke tšepe efe e nang le Porous?

A:Bakeng sa Metal e Tloaelehileng ha e na li-porous tse nyane.

Empa batho ba fumane hore tšepe e 'ngoe e na le ts'ebetso e ikhethang joalo ka ho sefa, ho joalo le ho feta

tšepe ho etsa ka porous by sintered technology, ho etsa hore e be mefuta ea boqapi

sintered metal elements to used as filters, ho sefa litšila ka khase kapa mokelikeli, ka

taelo ea ho fihlela sepheo sa tlhoekiso

U Etsa Joang Hore Metal Porous?

A:Hajoale, re atisa ho sebelisa mokhoa oa sintering, ho hlahisa litlolo tse fapaneng tsa tšepe

ka libopeho bakeng sa lits'ebetso tse fapaneng tsa boenjiniere ho fihlela sepheo sa ho sefa

Sesebelisuoa se Senyehileng ka ho Fetisisa ke sefe?

A:Ho fihlela joale, lisebelisoa tsa tšepe tse tsebahalang joalo ka li-filters ke tse latelang;

- Sefe ea tšepe e se nang tšepe; 316L, 304L, 310, 347 le 430

- Boronse

- Inconel® 600, 625 le 690

- Nickel200 le Monel® 400 (70 Ni-30 Cu)

- Titanium

- Alloys

Na koporo ke tšepe e nang le masoba?

Lisebelisoa tse ngata li ntse li sebelisa tšepe ea koporo ea koporo, hobane e theko e tlase.

empa ke mosing ke nako ea ts'ebeletso e ke keng ea nka nako e telele ho feta lisebelisoa tse ling tsa boleng, joalo ka

ts'epe e sa beng le mabali.

Phapang ke efe pakeng tsa porous le non-porous?

A:Phapang e Khōlō bakeng sa porous le e seng porous ke , porous metal e ka lumella khase kapa mokelikeli ho feta.

empa bao e seng porous ha ba khone.

Haeba u ntse u rata ho tseba haholoanyane kasintered filter sebetsa molao-motheo, ka kopo sheba lintlha tsa rona tsa ho hlahloba blog.

U ntse u na le Lipotso 'me u rata ho tseba lintlha tse ling bakeng saSintered Metal Filter, Ka kopo ikutloe u lokolohile ho Iteanya le Rona Hona joale.

Hape U ka khonaRe romelle ImeileKa ho toba ka tsela e latelang:ka@hengko.com

Re tla khutlisa ka lihora tse 24, re leboha mokuli oa hau!

Re romelle molaetsa oa hau: