Sintering ke eng?

Ho bonolo ho re, Sintering ke mokhoa oa ho phekola mocheso o sebelisetsoang ho fetola thepa ea phofo hore e be boima bo tiileng, ntle le ho fihla boemong ba ho qhibiliha ka ho feletseng.

Phetoho ena e etsahala ka ho futhumatsa thepa e ka tlas'a ntlha ea ho qhibiliha ho fihlela likaroloana tsa eona li khomarelana.Sintering e sebelisoa haholo liindastering tse fapaneng tse kang metallurgy, ceramics, esita le khatiso ea 3D ho hlahisa thepa e teteaneng le e matla ho tloha phofo.

Empa na u ne u tseba hore taba ea ho bina ha se ntho e qapiloeng kajeno?

Ha e le hantle, tšimoloho ea eona e ka saloa morao ho pota 3000 BC, ha e ne e sebelisetsoa ho etsa lintho tsa ceramic.Kutloisiso ea sejoale-joale ea mahlale le tšebeliso e atileng ea indasteri ea sintering, leha ho le joalo, e tsoetse pele haholo lekholong le fetileng la lilemo.

Joalo ka ha u ka inahanela, sintering e bapala karolo ea bohlokoa mefuteng e mengata ea lits'ebetso.Ho tloha ho ho etsa li-spark plugs, li-ceramic capacitor, le meqhaka ea meno ho isa ho ho aha likarolo tsa indasteri ea theknoloji e phahameng, sintering e ipakile e le ea bohlokoa haholo.

Mefuta e sa tšoaneng ea Sintering

Kaha joale ua tseba hore na sintering ke eng le hore na e 'nile ea sebelisoa joang ho pholletsa le histori, ke nako ea ho u tsebisa ka mefuta e fapaneng ea ho bina.E, ho na le mekhoa e mengata ea ho etsa sebe!

Pele holimoke solid-state sintering.Mofuta ona ke mokhoa o tloaelehileng ka ho fetisisa le o tloaelehileng oa sintering.Mona, thepa e phofshoana e futhumatsoa ho fihlela likaroloana li qala ho kopana.Ho tšoana le ha u ka haha qhobosheane ea lehlabathe - lithollo tsa lehlabathe li khomarelana, empa ha li qhibilihe.

E 'ngoe,re na le mokelikeli phase sintering.Mofuta ona o kenyelletsa motsoako oa lisebelisoa tse peli kapa ho feta.Motsoako ona o futhumatsoa hoo se seng sa lisebelisoa se qhibilihang ebe se etsa mokelikeli, e leng se thusang ho kopanya likaroloana tse tiileng tse setseng.

Ea borarolethathamong le kentsoe sintering.Tabeng ena, ho sebelisoa li-additive kapa catalyst ho potlakisa ts'ebetso ea sintering.Nahana ka ho eketsa tomoso hlama - e etsa hore bohobe bo phahame ka potlako.

Qetellong,ho na le mekhoa ea sintering e thusang khatello joalo ka ho tobetsa hot le spark plasma sintering.Joalokaha lebitso le bontša, mekhoa ena e sebelisa khatello hammoho le mocheso ho potlakisa ts'ebetso ea sintering le ho hlahisa lisebelisoa tse teteaneng.

Mofuta o mong le o mong oa sintering o na le melemo ea ona mme o sebelisetsoa lits'ebetso tse ikhethileng.Khetho e itšetlehile ka lintlha tse kang thepa e sebelisoang, thepa e lakatsehang ea sehlahisoa sa ho qetela le thepa e teng.Likarolong tse tlang, re tla hlahlobisisa lisebelisoa tse khethehileng tsa sintered le ts'ebetso ea sintering ka boeona.

Lula u mametse bakeng sa lintlha tse ling tse khahlang tsa lefatše la sintering!

Ho hlahloba Lisebelisoa tse Sintered

Ebe Ka mor'a moo re hloka ho utloisisa mefuta e fapaneng ea lisebelisoa tsa sintered.

Kea kholoa ha joale, u se u ntse u utloisisa mokhoa oa ho bina.Empa ho thoe’ng ka lihlahisoa tsa tšebetso ee e thahasellisang?

E 'ngoe ea lisebelisoa tse atisang ho hlahisoa ke tšepe e sintered.Mokhoa ona o kenyelletsa ho kopanya le ho etsa phofo ea tšepe tlas'a mocheso, ho e fetola tšepe e tiileng.Phello ke tšepe e nang le tekanyo e phahameng ea bohloeki le ho tšoana.Sintered metal e ka fumanoa liindastering tse sa tšoaneng, ho tloha likarolong tsa likoloi ho ea ho li-implants tsa bongaka, ka lebaka la matla a eona le ho feto-fetoha ha maemo.

E 'ngoe,ha re bueng ka lejoe le sintered.Sintered Stone e hlahisoa ka ho sebelisa mocheso le khatello ho liminerale tsa tlhaho, letsopa le feldspar, ho etsa thepa e batlang e ke ke ea senyeha.Hangata u tla fumana lejoe le sirelelitsoeng libakeng tse nang le sephethephethe se phahameng joalo ka li-countertops tsa kichineng kapa lithaele tsa kamore ea ho hlapela, moo ho tšoarellang e leng senotlolo.

Sintering e boetse e bapala karolo ea bohlokoa ho lirafshoa.Ts'ebetso ena e re thusa ho bopa li-ceramics hore e be libopeho tse ngata tse nang le lijeometri tse rarahaneng tse neng li ke ke tsa khoneha ka mekhoa ea setso.Ho tloha ho lithaele tsa ceramic ho isa ho letsopa, sintering e bile le phello ea phetoho lekaleng lena.

Qetellong,ho na le lisebelisoa tse ling tse khethehileng tsa sintered tse lokelang ho hlahlojoa.Tsena li tloha ho lisebelisoa tse kopantsoeng, joalo ka metsoako ea tšepe-ceramic, ho ea ho lisebelisoa tse sebetsang hantle, moo sebopeho se fapaneng ho pholletsa le karolo.

Sintering Process Hlalosa

Ha re tsoeleng pele ho tloha lihlahisoa ho ea ts'ebetsong ka boeona.Sintering e etsahala joang, 'me mehato ea bohlokoa e amehang ke efe?

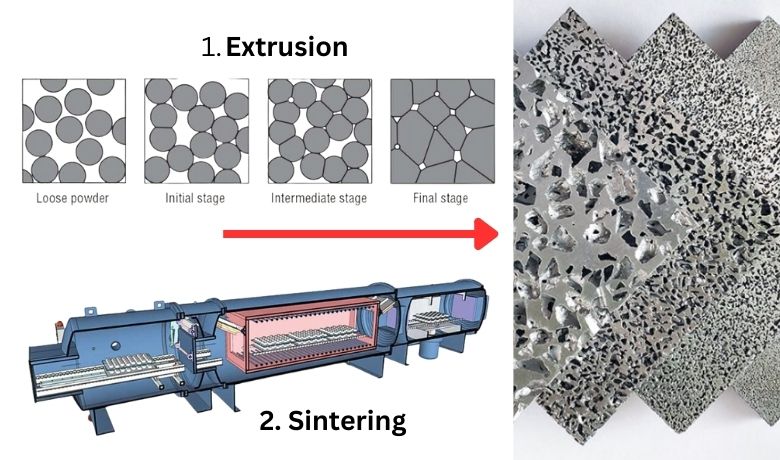

Ho qala, mehato ea pele ho sintering ke ea bohlokoa.Thepa e tala, ebang ke tšepe, ceramic, kapa ho seng joalo, e tlameha ho lokisoa ka mokhoa oa phofo.Phofo ena e ntan'o bōptjoa hore e be sebopeho se lakatsehang, hangata ka mokhoa o bitsoang 'green compacting'.

E latelang ho latela pelo ea ts'ebetso: ts'ebetso ea sintering.Phofo e bōpehileng e futhumatsoa sebakeng se laoloang, hangata seboping, ho ea mocheso o ka tlaase ho sebaka sa ho qhibiliha.Sena se lumella likaroloana ho kopana ntle le ho qhibiliha ka ho feletseng, ho etsa boima bo tiileng.

Hang ha ts'ebetso ea sintering e phethiloe, thepa e kena karolong ea ho pholile.Sena se hloka ho laoloa ka hloko, kaha ho pholisoa ka potlako ho ka lebisa ho petsoha kapa mathata a mang a sebopeho.Ho pholile butle ho lumella thepa hore e lule le ho tiisa ka katleho.

Qetellong,re ke ke ra lebala lintlha tse amang sintering, ka ho khetheha, mocheso le nako.Thempereichara ea sintering e lokela ho ba holimo ka ho lekaneng ho nolofatsa tlamahano empa e be tlase ho lekana ho thibela ho qhibiliha ho feletseng.Ka mokhoa o ts'oanang, nako eo thepa e e qetang e le sintering e ka ama haholo thepa ea sehlahisoa sa ho qetela.

Karolong e latelang ea saga ea rona ea sintering, re tla qoela ka botebo ka har'a li-filters tse sintered mme re utolle maemo a hlokahalang bakeng sa sintering.Kahoo lula u mametse!

Lisefe tse Sintered: Leseli la Ts'ebeliso

Re se re koahetse lintho tsa motheo tsa ho sintering, re hlahlobile mefuta e fapaneng ea lisebelisoa tsa sintered, 'me re buisane ka mokhoa oa ho sinta ka botlalo.

Joale, ha re shebeng ats'ebeliso e khethehileng ea li-filters tsa sintering.

Mohlomong e 'ngoe ea likopo tse hlokomelehang ka ho fetesisa tsa sintering ke ho theheng li-filters tsa tšepe tse sirelelitsoeng.Li-filters tsena li hlahisoa ho tsoa ho liphofshoana tsa tšepe, tse kopanngoeng le ho silafatsoa ho etsa filtara e porous empa e le matla.Boholo ba li-filters tsena bo ka laoloa ka nepo, 'me bo fana ka bokhoni bo phahameng ba ho sefa ha bo bapisoa le li-filters tse tloaelehileng tse lohiloeng tsa mesh.

U ka ipotsa,hobaneng sebelisali-filters tsa tšepe tse sintered?Karabo e itšetlehile ka ho tšoarella ha tsona le ho hanyetsa mocheso o phahameng le likhatello.Thepa ena e etsa hore li-filters tsa tšepe tse sirelelitsoeng e be tsa bohlokoa liindastering ho tloha ho tsa meriana ho isa ho li-petrochemicals le tlhahiso ea lijo le lino.

Tšebeliso e 'ngoe e khahlang ea sintering in filtration ke sintered glass filter.Tsena li entsoe ka ho kopanya likaroloana tse nyenyane tsa khalase mochesong o phahameng.Hangata li sebelisoa lilaboratoring bakeng sa ho sefa le ho ajoa ha khase ka lebaka la ho hanyetsa lik'hemik'hale tse phahameng le boholo bo nepahetseng ba pore.

Li-filters tse sintered, ekaba tšepe kapa khalase, li fana ka mohlala oa bokhoni ba ho etsa lisebelisoa tsa boleng bo holimo tse nang le melemo e ikhethang.

Ho Utloisisa Maemo a Sintering

Jwale, ha re lebiseng tlhokomelo ya rona ho maemo a sintering.Ha re bua ka mokhoa oa sintering, maemo ao e etsahalang tlas'a oona ke a bohlokoa ka ho fetisisa.

Ea pele,mocheso oa sintering o phetha karolo ea bohlokoa ts'ebetsong.E hloka ho ba ka tlase ho ntlha ea ho qhibiliha ea thepa, ho lumella likaroloana ho kopana ntle le ho qhibiliha ka ho feletseng.Ke tekano e bonolo e ka amang haholo boleng ba sehlahisoa sa ho qetela.

Joaleho na le taba ea khase.U ka 'na ua ipotsa, "Ke khase efe e sebelisoang ho sintering?"Ka tloaelo, sintering e etsoa sebakeng se laoloang ho thibela liketso tse sa rateheng pakeng tsa thepa le likhase tse potolohileng.Hangata, likhase tse sa sebetseng tse kang naetrojene kapa argon li sebelisoa, le hoja khetho e khethehileng e itšetlehile ka thepa e sintered.

Khatello e boetse e kena tšebetsong, haholo-holo mekhoeng e thusang ea khatello ea maikutlo.Khatello e phahameng e ka fella ka lisebelisoa tse teteaneng, kaha likaroloana li qobelloa ho atamelana.

Qetellong,thepa le thepa e sebelisoang ke lintlha tsa bohlokoa.Lisebelisoa tse fapaneng li arabela ka tsela e fapaneng mocheso le khatello, tse hlokang maemo a fapaneng bakeng sa sintering e nepahetseng.Mofuta oa sebōpi kapa mochini oa sintering o ka boela oa ama ts'ebetso, joalo ka ha re tla tšohla karolong e latelang.

Lula u mametse ha re ntse re hlahloba haholoanyane ka mechini ea sintering le karolo ea eona ts'ebetsong ea ho qoelisa!

Thepa ea Sintering: Ho Sheba Mechini ea Sintering

Ho fihlela joale, esale re ntse re hlahloba ka botlalo mohopolo oa sintering, lisebelisoa tsa sintered, le ts'ebetso ka boeona.

Joale ha re boneng sebapali se ka sehloohong se ka morao ho papali:mochine oa sintering.

Mochini oa sintering ke lejoe la sekhutlo la ts'ebetso ea sintering.Empa hantle-ntle mochini oa sintering ke eng?Ha e le hantle, ke sebōpi se khethehileng se etselitsoeng ho etsa sintering tlas'a maemo a laoloang ka hloko.

Ho na lemefuta e fapaneng ya metjhini e sinteringe fumanehang, e 'ngoe le e' ngoe e loketse lisebelisoa tse fapaneng le mekhoa ea sintering.

1. Tsena li kenyelletsaMechini e sa khaotseng ea sintering(e sebelisoa liindastering tse hlokang tlhahiso e phahameng haholo),

2.Mechini ea ho hlapa ka bongata(e tloaelehileng haholo ho li-lab kapa bakeng sa tlhahiso ea molumo o tlase), le

3. Mechini e hloekisang li-vacuum(tse lumellang ho sintering sebakeng se se nang metsi kapa se laoloang).

Tsela eo mochini oa sintering o sebetsang ka eona e otlolohile empa e ea khahla.E futhumatsa thepa e phofshoana ka mokhoa o ts'oanang ho mocheso o itseng, e boloka mocheso ona ka nako e reriloeng esale pele, ebe e pholisa thepa butle-butle, kaofela ha eona e ntse e netefatsa hore sepakapaka se ka hare se laoloa.

Ho bohlokoa ho khetha mochini o nepahetseng oa sintering 'me ho ipapisitse le lintlha tse' maloa, ho kenyelletsa le lisebelisoa tse lokelang ho siloa, tlhahiso e lakatsehang, le maemo a khethehileng a sintering a hlokahalang.

Bohlokoa le Bokamoso ba ho Sintering

Joale ke nako ea ho nahana ka taba e kholoanyane:Sintering e sebedisetsoa eng, lehobaneng e le bohlokoa?

Thelits'ebetsotsa sintering li ngata ebile li fapane.E sebelisetsoa ho etsa lihlahisoa tse teteaneng, tse tšoarellang tse nang le li-geometri tse rarahaneng, ho tloha likarolong tsa indasteri ho ea ho thepa ea bareki.Sintering e re fa monyetla oa ho hlahisa lisebelisoa tsa boleng bo holimo, joalo ka tšepe e sirelelitsoeng le lifilthara tsa sintered, tse nang le thepa e ikhethang joalo ka boholo ba pore e laoloang le ho tšoarella ho ntlafetseng.

Empabokamoso ba ho sintering bo shebahala joang?Mekhoa e hlahang e fana ka maikutlo a ho eketseha ha tšebeliso ea mekhoa ea sintering e thusang khatello bakeng sa ho hlahisa thepa e tsoetseng pele.Nts'etsopele ea mechini e sebetsang hantle haholo ea sintering le ts'ebeliso ea sintering tlhahisong ea li-additive (3D printing) ke mekhoa e meng e ts'episang.

Leha ho na le tsoelo-pele ena, sintering e boetse e tobane le mathata, joalo ka ho fumana taolo e kholo holim'a ts'ebetso le ho fokotsa tšebeliso ea matla.Ho sebetsana le tsena e tla ba senotlolo sa ho notlolla bokhoni bo felletseng ba ho bina nakong e tlang.

Qetello:Sintering, leha e le ts'ebetso e rarahaneng, e na le tšusumetso e kholo ho liindasteri tse fapaneng.Bokhoni ba eona ba ho fetola li-powders tse bonolo hore e be lisebelisoa tse matla, tse rarahaneng li etsa hore e be mokhoa oa bohlokoa haholo.Ha re ntse re lebeletse bokamoso, ho iphetola ha lintho le ntlafatso ea sintering li tšepisa menyetla e thabisang bakeng sa lisebelisoa tse ncha le lisebelisoa.

LBH

1. Mokhoa oa sintering ke ofe?

Sintering ke mokhoa oa ho phekola mocheso o fetolang lisebelisoa tse phofshoana hore e be boima bo tiileng ntle le ho qhibiliha thepa ka ho feletseng.E kenyelletsa ho futhumatsa thepa e phofshoana ka tlas'a ntlha ea eona ea ho qhibiliha ho fihlela likaroloana li qala ho khomarelana, ho etsa boima bo tiileng.Ts'ebetso ena e sebelisoa liindastering tse fapaneng tse kang metallurgy, ceramics, and additive products ho hlahisa thepa e teteaneng le e matla ho tloha phofo.

2. Sintering e sebetsa joang?

Ts'ebetso ea sintering e kenyelletsa mekhahlelo e meraro e meholo: ho futhumatsa, ho tšoara, le ho pholile.Thepa e entsoeng ka phofo e qala ho kopanngoa le ho etsoa sebopeho se lakatsehang, ebe se futhumatsoa sebakeng se laoloang ho mocheso o ka tlase ho sebaka sa ho qhibiliha.Mocheso o etsa hore likaroloana li kopane, ho etsa boima bo tiileng.Ka mor'a ho boloka mocheso ona ka nako e reriloeng esale pele, thepa e ntan'o pholile butle-butle ho thibela ho phunyeha kapa litaba tse ling tsa sebopeho.

3. Ke lisebelisoa life tse ka sitsoang?

Mefuta e mengata ea thepa e ka chesoa, ho kenyeletsoa tšepe, ceramics, polasetiki le likhalase.Lisebelisoa tse fapaneng li hloka maemo a fapaneng a sintering, joalo ka mocheso, khatello le sepakapaka.Lisebelisoa tse ling li ka tšeloa ka ho toba, ha tse ling li hloka li-additives kapa li-binders ho tsamaisa ts'ebetso.

4. Sintered filter ke eng, hona ke hobane'ng ha e sebelisoa?

Sintered filter ke mofuta oa filthara o hlahisoang ka mokhoa oa sintering.E ka etsoa ka tšepe, ceramic, kapa likhalase tse phofshoana, tse kopantsoeng le ho futhumatsoa ho fihlela likaroloana li kopana.Boholo ba pore ea li-filters tsena bo ka laoloa ka nepo, ho fana ka bokhoni bo phahameng ba ho sefa ha bo bapisoa le lihloela tsa setso.Li-filters tse sintered li tšoarella nako e telele ebile li hanana le mocheso o phahameng le likhatello, li li etsa hore li sebelisoe liindastering tse fapaneng joalo ka meriana, lik'hemik'hale tsa petrole, le tlhahiso ea lijo le lino.

5. Sintering e sebelisoa joang tlhahisong ea li-additive (3D printing)?

Ha ho etsoa li-additive, kapa khatiso ea 3D, sintering e sebelisoa ka mekhoa e kang selective laser sintering (SLS) le direct metal laser sintering (DMLS).Mekhoa ena e kenyelletsa ho sebelisa laser ho sinter lintho tse entsoeng ka phofo ka lera, ho haha ntho e lakatsehang ea 3D.Bokhoni ba ho laola ts'ebetso ea sintering ka nepo bo etsa hore ho khonehe ho hlahisa libopeho tse rarahaneng le li-geometri tseo ho ka bang thata kapa ho ke keng ha khoneha ho li fihlela ka mekhoa ea setso ea tlhahiso.

6. Bokamoso ba ho bina ke bofe?

Bokamoso ba ho bina bo shebahala bo ts'episa, ha tsoelopele ea theknoloji e bula menyetla e mecha.Ka mohlala, mekhoa ea sintering e thusoang ke khatello e ntse e ata haholo bakeng sa ho hlahisa thepa e tsoetseng pele.Nts'etsopele ea mechini ea sintering e sebetsang hantle le e nepahetseng haholoanyane, le ts'ebeliso ea sintering tlhahisong ea tlatsetso, ke mekhoa e meng e ts'episang.Leha ho le joalo, liqholotso tse kang ho fumana taolo e kholo holim'a ts'ebetso le ho fokotsa tšebeliso ea matla li hloka ho rarolloa ho bula ka botlalo bokhoni ba ho sintering.

Hore na o batla ho kenya tšebetsong lits'ebetso tsa sintering ts'ebetsong ea hau kapa ho batla lisebelisoa tsa boleng bo holimo bakeng sa merero ea hau, HENGKO e teng ho u thusa.Sehlopha sa rona sa litsebi se ikemiselitse ho fana ka likeletso, litharollo le lits'ebeletso tse tsamaellanang le litlhoko tsa hau tse ikhethileng.

Seke oa tsilatsila ho ikopanya le rona bakeng sa lintlha tse ling mabapi le ts'ebetso e khahlang ea ho bina kapa ho hlahloba mefuta e mengata ea lihlahisoa le lits'ebeletso tsa rona.Re romelle lengolo-tsoibila feela hoka@hengko.com, mme re tla kopana haufinyane.re ikemiselitse ho u thusa ho fetola menyetla ea phofshoana hore e be katleho e tiileng!

Re romelle molaetsa oa hau:

Nako ea poso: Jul-03-2023